Understanding Cylinder Head Function

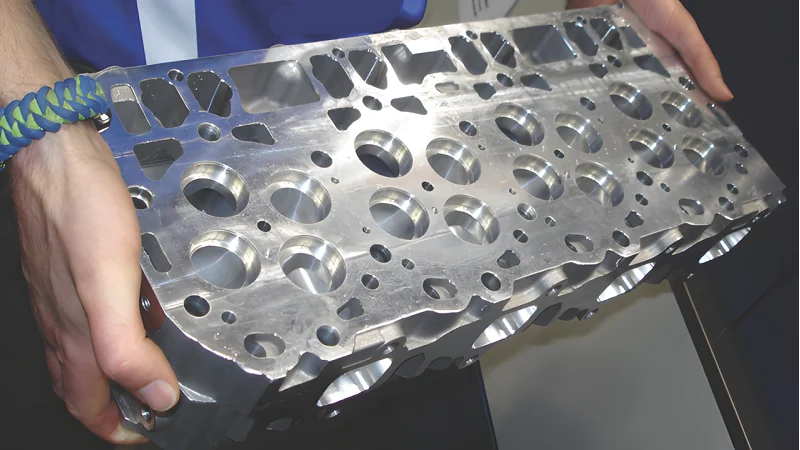

- Valves and valve seats – Control intake and exhaust flow.

- Camshafts and timing components – Manage valve timing and lift.

- Cooling passages – Circulate coolant to prevent overheating.

- Combustion chambers – Where fuel and air ignite to generate power.

A properly functioning cylinder head ensures efficient combustion, optimal airflow, and minimal energy loss. Any damage, warping, or design limitation can compromise engine performance and longevity.

Signs You Might Need Aftermarket Cylinder Heads

1. Engine Performance Upgrades

- Improved port shapes and sizes – Enhancing airflow and volumetric efficiency.

- Higher-quality materials – Allowing the engine to withstand higher combustion pressures.

- Optimized valve angles and sizes – Maximizing intake and exhaust efficiency for specific applications.

These modifications can result in significant horsepower and torque gains, which stock heads may not safely accommodate.

2. Repairing Severe Damage

- Cracks in the head casting.

- Warped surfaces that prevent proper sealing.

- Burned or pitted valves.

- Persistent coolant or oil leaks.

In such cases, aftermarket heads can be a viable replacement, particularly if OEM parts are expensive, discontinued, or prone to recurring issues. Aftermarket heads often provide equivalent or improved quality while offering options for enhanced durability.

3. Engine Swaps or Custom Builds

- Porting configurations – To match custom intake and exhaust setups.

- Compatibility with high-performance components – Like aftermarket camshafts or forced induction kits.

- Weight reduction – Some aftermarket heads are cast in aluminum to reduce overall engine weight.

Custom builds often demand non-standard cylinder head solutions, making aftermarket options an essential consideration.

4. Improving Fuel Efficiency and Emissions

- Enhanced airflow leading to more complete combustion.

- Reduced carbon buildup on valves and ports.

- Optimized combustion chamber design for cleaner fuel burn.

While this is more relevant to performance-oriented or older engines being retrofitted with newer technologies, it is an important factor for those looking to maintain efficiency alongside performance.

5. Extending Engine Lifespan

- Superior thermal management to prevent overheating.

- Harder valve seats and guides for prolonged durability.

- Reinforced construction to withstand higher pressures over time.

For vehicles that see extreme operating conditions, investing in aftermarket heads can prevent recurring maintenance issues and reduce long-term costs.

Choosing the Right Aftermarket Cylinder Head

Material

- Cast iron heads are durable and resist wear, making them ideal for heavy-duty applications.

- Aluminum heads are lighter and dissipate heat faster, making them suitable for high-performance engines where weight reduction and thermal efficiency are priorities.

The choice of material directly affects engine performance, weight, and heat management.

Port Design

- Port shape and cross-sectional area.

- Smoothness of internal surfaces to reduce turbulence.

- Compatibility with existing intake and exhaust manifolds.

Valve Configuration

Upgrading to aftermarket heads may also involve changes to valves, including size, angle, and number per cylinder. Larger valves and optimized valve angles can improve airflow, but must be balanced with engine compression and fuel requirements.

Head Gasket Compatibility

Aftermarket heads may have different combustion chamber volumes or surface finishes, which can affect gasket selection. Ensuring proper sealing is crucial to prevent leaks and maintain compression.

Manufacturer Reputation

Not all aftermarket cylinder heads are created equal. Quality control, material selection, and machining precision vary widely. Choosing reputable manufacturers with proven performance and reliability records is essential to avoid potential engine damage.

Installation Considerations

- Torque specifications – Follow manufacturer recommendations closely to avoid warping or leaks.

- Head gasket selection – Ensure compatibility with the aftermarket head.

- Camshaft and valve timing adjustments – Required if the aftermarket head changes geometry.

- Coolant and oil passages – Verify alignment to prevent flow restrictions.

Professional installation is recommended, particularly for high-performance engines, to ensure optimal performance and reliability.

Cost vs. Benefit Analysis

Aftermarket cylinder heads can vary in price from several hundred to several thousand dollars. When considering a replacement or upgrade, weigh the benefits against the costs:

- Performance gains – Are you seeking increased horsepower, torque, or efficiency?

- Durability improvements – Will the aftermarket head extend engine life or prevent recurring repairs?

- Compatibility with upgrades – Does your build require heads that OEM cannot support?

For some users, repairing or reconditioning the original cylinder head may be sufficient. However, for high-performance or specialized applications, the benefits of aftermarket heads often outweigh the costs.

Conclusion

Aftermarket cylinder heads are not just a replacement option—they can be a critical component in performance enhancement, engine repair, and custom builds. Whether you are upgrading for more power, addressing severe head damage, or optimizing a custom engine, aftermarket heads provide flexibility and options beyond what OEM parts can offer. Key factors in deciding include performance requirements, engine condition, material choice, port and valve design, and installation considerations. By carefully assessing your needs and choosing a quality aftermarket solution, you can enhance your engine’s performance, reliability, and longevity.

Investing in the right aftermarket cylinder head can make a significant difference, turning a standard engine into a high-performing, durable, and efficient power unit.