When it comes to vehicle engines, most buyers focus on horsepower or torque numbers. But the real heart of an engine lies in its ability to move air and fuel efficiently. At the center of this process is the cylinder head. Without a properly designed and manufactured cylinder head, even the most robust engine block and pistons cannot achieve peak performance.

For businesses sourcing high-quality cylinder heads, understanding their construction, types, and maintenance requirements is essential. Our factory specializes in precision-engineered cylinder heads, designed to meet OEM standards while allowing customization for high-performance and industrial applications.

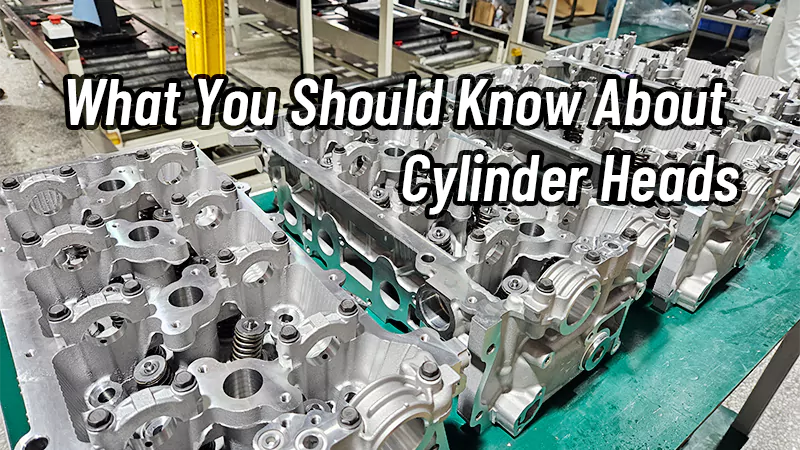

The Role of Cylinder Heads

Your engine block contains all the moving components—the crankshaft, pistons, and connecting rods—that convert combustion energy into rotational power. However, the cylinder head is what turns those cylinders into controlled combustion chambers. It manages airflow, controls intake and exhaust valves, houses cooling passages, and ensures proper ignition or fuel injection.

For automotive businesses, the quality and precision of cylinder heads directly affect engine performance, reliability, and longevity. High-performance vehicles and modified engines demand heads that optimize airflow, handle higher RPMs, and maintain stability under intense driving conditions. Our factory ensures every cylinder head meets these exacting standards.

Anatomy of a Cylinder Head

While designs vary, most cylinder heads include:

- Combustion Chambers: Shape and volume directly affect compression ratio, efficiency, and power output.

- Valves and Ports: Intake and exhaust ports with valves control the airflow into and out of the cylinder. Intake valves are usually larger than exhaust valves for optimal breathing.

- Valve Train Components: Depending on engine design, the head may house camshafts, rocker arms, pushrods, or lifters.

- Cooling Passages: Water jackets or cooling channels prevent overheating, a common cause of head failure.

- Spark Plug or Injector Mounts: Critical for fuel ignition or direct injection systems.

- Gasket Surfaces: Precision-machined surfaces ensure proper sealing between the head and block, preventing leaks.

Our factory produces cylinder heads from aluminum or cast iron, depending on application, balancing weight, heat dissipation, and durability.

Common Cylinder Head Types

In modern engines, only two types of cylinder heads are commonly used. Both types are supported by our manufacturing capabilities and can be customized for volume production or high-performance needs.

Overhead Valve (OHV / Pushrod) Heads

OHV engines, also known as pushrod engines, place the valves in the cylinder head but operate them via pushrods connected to a camshaft in the engine block. This design improves airflow compared to older flathead engines and allows larger engine displacement.

Overhead Cam (OHC) Heads

OHC engines have one or two camshafts directly in the cylinder head, operating valves without pushrods. DOHC (dual overhead cam) heads allow more precise valve timing, higher RPM performance, and improved airflow.

Common Cylinder Head Issues and Solutions

Even the best engines can face cylinder head problems if maintenance or cooling systems fail. Common issues include:

- Overheating: Can warp or crack the head. Aluminum heads dissipate heat quickly but may warp under repeated high temperatures. Cast iron heads are more robust but slower to cool. Our factory designs heads to maintain structural integrity under prolonged high-load conditions.

- Freezing: Insufficient antifreeze can crack water jackets. We provide precision-cast cooling passages to prevent failure in extreme temperatures.

- Mechanical Damage: Valve breakage, detonation, or foreign object damage can compromise the head. Factory-grade materials and quality control reduce the risk of early failure.

Regular inspection and proper cooling system maintenance extend the service life of cylinder heads. For B2B clients, sourcing from a reliable factory ensures consistent quality and fewer warranty claims.

Conclusion

Cylinder heads are a critical component in engine operation. They control airflow, manage combustion, and regulate temperature. For businesses sourcing engine components, choosing a high-quality, factory-supplied cylinder head is essential to ensure reliability, performance, and customer satisfaction.

Cylinder heads are a critical component in engine operation. They control airflow, manage combustion, and regulate temperature. For businesses sourcing engine components, choosing a high-quality, factory-supplied cylinder head is essential to ensure reliability, performance, and customer satisfaction.

Your engines deserve cylinder heads built with precision, durability, and performance in mind. Partnering with our factory ensures that your business can supply or maintain engines that operate efficiently, reliably, and powerfully—every time.