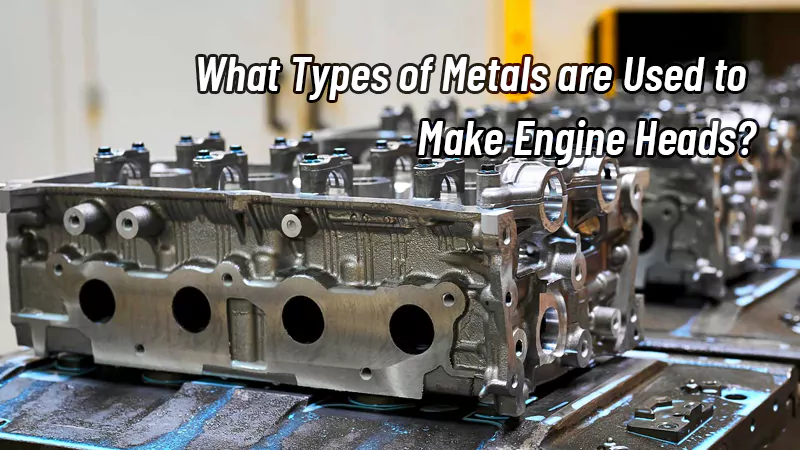

The engine head, also known as the cylinder head, is one of the most important parts of a car’s engine. It sits on top of the engine block and forms the combustion chamber where fuel burns to generate power. Because the cylinder head is exposed to high temperatures, extreme pressure, and constant stress, the material it is made from plays a crucial role in engine performance, longevity, and efficiency. Choosing the right metal can mean the difference between an engine that runs smoothly for hundreds of thousands of miles and one that experiences warping, cracking, or early failure.

Cast Iron

Traditionally, cast iron has been a popular choice for engine heads. Cast iron is extremely strong and resistant to wear, making it ideal for heavy-duty engines or older vehicles where durability outweighs weight concerns. It handles high temperatures well and is less prone to warping compared to many other metals. However, cast iron is heavy, which can reduce fuel efficiency and overall vehicle performance. It is also more difficult to machine into complex shapes, which limits some design possibilities. Despite these limitations, cast iron remains in use today for trucks, industrial engines, and some high-torque applications because of its proven reliability.

Aluminum Alloy

In modern passenger vehicles, aluminum alloy has become the dominant material for engine heads. Aluminum is lightweight, which helps improve fuel efficiency and vehicle handling. It also has excellent heat dissipation properties, allowing engines to run cooler and reducing the risk of overheating. Aluminum heads are easier to machine and shape into complex designs, which gives engineers more flexibility in optimizing airflow and combustion efficiency. The main drawback is that aluminum is softer than cast iron and can warp under extreme heat if not reinforced. To address this, manufacturers often use aluminum alloys that include elements like silicon or copper, improving strength while retaining lightness. Today, aluminum engine heads are common in almost all passenger cars and many high-performance vehicles.

Magnesium Alloy

For high-performance and racing applications, magnesium alloy is sometimes used. Magnesium is even lighter than aluminum, which can significantly reduce engine weight and improve vehicle performance. Its heat dissipation is also very good, making it ideal for engines that operate at extreme temperatures. However, magnesium is more expensive and less durable than aluminum or cast iron. It also requires careful handling during manufacturing to prevent defects. As a result, magnesium heads are rare in mass-produced vehicles and are usually reserved for racing cars or high-end sports cars where every kilogram matters.

Titanium

Titanium is a premium metal occasionally used for cylinder heads in elite racing or aerospace engines. Titanium offers exceptional strength while remaining lightweight. It also resists high temperatures and corrosion better than most other metals. The challenge is its cost, which is extremely high, and the difficulty of machining it into complex shapes. Titanium heads are therefore very uncommon in consumer vehicles, but they demonstrate what is possible when performance and durability are prioritized over cost.

How Manufacturers Choose the Right Metal?

The choice of metal for an engine head depends on several factors. The type of vehicle is a major consideration. Trucks and heavy-duty vehicles often benefit from the durability of cast iron, while passenger cars tend to use aluminum to save weight and improve efficiency. Engine performance requirements also play a role. High-performance sports cars may utilize aluminum, magnesium, or even titanium to maximize power-to-weight ratio and cooling efficiency. Cost is another factor, with cast iron being the most economical, aluminum being mid-range, and magnesium or titanium reserved for premium applications. Modern production techniques, including advanced casting and CNC machining, have expanded the possibilities for aluminum and other alloys, allowing more complex and efficient designs.

Conclusion

Choosing the right metal for an engine head is crucial for optimal performance. Cast iron offers durability and heat resistance but is heavy, making it suitable for trucks and industrial engines. Aluminum provides a balance of light weight, strength, and excellent heat dissipation, making it the standard choice for most modern vehicles. Magnesium and titanium are reserved for high-performance and racing engines due to their lightweight and superior properties, though cost and manufacturing complexity limit their use. Steel, while strong, is mainly used for reinforcement or in specialized high-performance engines. Each metal brings its own advantages and compromises, and manufacturers select the best option based on vehicle type, engine requirements, and budget.

If you are looking for high-quality OEM engine cylinder heads or blocks, our factory specializes in producing durable, precise components. Whether you need aluminum, cast iron, or customized alloy heads, we provide solutions for passenger cars, trucks, and high-performance engines. Contact us today to discuss your requirements and receive a quote.