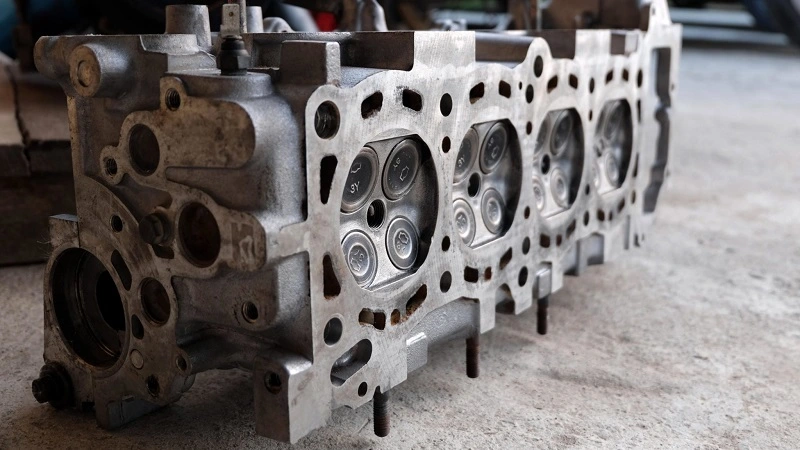

Why the Cylinder Head Is So Vulnerable

- Combustion temperatures exceeding 2,000°C inside the chamber

- Constant thermal expansion and contraction

- High clamping forces from head bolts

- Exposure to coolant, engine oil, fuel, and exhaust gases

The Most Common Cylinder Head Problem: Head Gasket Failure

What Is a Cylinder Head Gasket?

- Seal combustion pressure inside each cylinder

- Prevent coolant and oil from mixing

- Maintain proper compression

Why Head Gasket Failure Is So Common

- The aluminum cylinder head expands faster than the cast-iron block

- Uneven expansion reduces the clamping force on the gasket

- Local hot spots damage the gasket material

- The cylinder head may begin to warp

Common Symptoms of Cylinder Head and Head Gasket Problems

1. Engine Overheating

2. White Smoke from the Exhaust

3. Coolant Loss with No External Leak

4. Milky Oil or Sludge

5. Rough Idle and Misfires

Cylinder Head Warping: A Closely Related Issue

How Cylinder Heads Warp

Can a Warped Cylinder Head Be Repaired?

Cracked Cylinder Heads: Less Common but More Severe

Common Causes of Cylinder Head Cracks

- Severe or repeated overheating

- Sudden temperature changes (thermal shock)

- Casting defects or material fatigue

- Improper torqueing during installation

Cracks often form between valve seats, around spark plug holes, or near coolant passages.

Symptoms of a Cracked Cylinder Head

Valve Seat and Valve Guide Wear

Why Valve Components Wear

- Continuous high-speed operation

- Poor lubrication

- Contaminated engine oil

- Excessive exhaust heat

Worn valve guides allow oil to enter the combustion chamber, while damaged valve seats reduce compression and efficiency.

Symptoms of Valve-Related Cylinder Head Problems

- Blue smoke from the exhaust

- Increased oil consumption

- Loss of power

- Ticking or tapping noises

While these issues may not immediately disable an engine, they significantly reduce performance and longevity.

How Cooling System Failures Lead to Cylinder Head Damage

Common Cooling System Issues That Affect Cylinder Heads

- Low coolant levels: Insufficient coolant reduces heat dissipation and increases hot spots in the head.

- Failed thermostats: Malfunctioning thermostats prevent proper coolant circulation, leading to localized overheating.

- Blocked radiators: Deposits or debris reduce the radiator’s cooling efficiency.

- Faulty water pumps: Poor circulation exacerbates temperature spikes in the cylinder head.

- Air trapped in the system: Air pockets block coolant flow, causing uneven cooling and potential warping.

Why Regular Cooling System Maintenance Matters

Diagnosing Cylinder Head Problems Correctly

Common Diagnostic Methods

- Compression tests: Measure cylinder pressure to detect leaks.

- Leak-down tests: Identify whether pressure escapes from the cylinder head, valves, or gasket.

- Cooling system pressure tests: Detect internal leaks in the head or block.

- Exhaust gas analysis in coolant: Reveals if combustion gases are entering the cooling system.

- Visual inspection after disassembly: Confirms warping, cracks, or gasket damage.

Importance of Professional Diagnosis

Repair vs Replacement: What Makes More Sense?

Key Factors to Consider

- Degree of warping or cracking: Minor warping can often be machined, but severe cracks may require full replacement.

- Engine age and value: Older engines might benefit more from repair or replacement based on cost-effectiveness.

- Availability of replacement parts: Some engines have limited aftermarket support.

- Intended vehicle use: Commercial or high-performance engines often require higher reliability, favoring replacement.

In modern engines and commercial applications, replacement usually provides better long-term reliability than repeated repairs.

Preventing Cylinder Head Problems

Effective Preventive Measures

- Monitor engine temperature closely: Detect overheating early.

- Maintain proper coolant levels and quality: Ensure adequate heat transfer.

- Follow correct torque procedures: Proper installation prevents uneven stress.

- Avoid prolonged overheating: Minimize high-temperature exposure.

- Address cooling system issues immediately: Fix faults before they escalate into cylinder head damage.

Preventive maintenance is far less expensive than repairing a damaged cylinder head and protects overall engine longevity.

Why Cylinder Head Quality Matters

Importance for Businesses and B2B Applications

Final Thoughts

So, what is the most common cylinder head problem?

The answer is clear: head gasket failure caused by overheating, often combined with cylinder head warping. While other issues, such as cracks and valve wear, do occur, they are far less frequent and usually linked to extreme operating conditions.At XinJin Auto Parts, we are a factory-direct manufacturer specializing in high-quality engine components, including cylinder heads designed for durability, precision, and real-world reliability.

If you have questions about cylinder head applications, specifications, or sourcing for your business, feel free to reach out to us through our Contact Us page. Our team is always ready to support your needs with professional, factory-level solutions.