What Is Cylinder Head Skimming?

Cylinder head skimming, also known as cylinder head resurfacing, is a precision machining process that removes a thin layer of material from the cylinder head’s sealing surface. This restores flatness and smoothness, ensuring a perfect seal between the cylinder head and the engine block. Proper skimming prevents common engine problems such as gasket failure, coolant leaks, and compression loss.

Why Does Cylinder Head Warping Occur?

Cylinder head warping is a frequent cause for cylinder head skimming. Understanding why warping happens helps prevent costly repairs:

- Engine Overheating: Overheating is the primary cause of cylinder head warping. Faulty cooling systems, low coolant levels, or clogged radiators cause uneven heat distribution and thermal expansion, leading to distortion.

- Poor Maintenance: Neglecting coolant changes or ignoring leaks allows corrosion and buildup, damaging the cylinder head surface.

- Detonation and Pre-Ignition: Abnormal combustion causes excessive pressure and heat, stressing the cylinder head and causing surface damage.

- Physical Damage: Mishandling during repairs or accidental impact can deform the cylinder head.

Why Is Cylinder Head Skimming Necessary?

- Restores Sealing Surface Flatness: Warped or damaged cylinder heads prevent proper sealing of the head gasket, leading to coolant leaks, loss of compression, and engine overheating.

- Prevents Head Gasket Failure: A flat cylinder head surface ensures the head gasket compresses evenly, increasing durability and engine reliability.

- Improves Engine Performance and Efficiency: Skimming ensures consistent combustion chamber volume, resulting in optimal fuel combustion and reduced emissions.

- Extends Engine Lifespan: Proper sealing and heat dissipation reduce engine wear and avoid costly repairs.

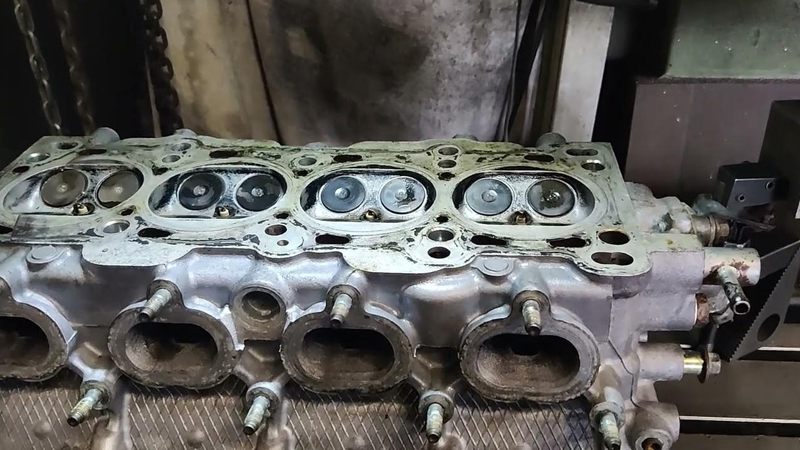

How Is Cylinder Head Skimming Performed?

- Inspection: The cylinder head is removed and checked for warping and cracks using precise measuring tools.

- Machining: Specialized milling machines remove a thin layer from the cylinder head surface to restore flatness.

- Quality Check: After skimming, the head is re-measured to meet manufacturer flatness specifications.

- Reassembly: The cylinder head is cleaned and reinstalled with a new head gasket.

How to Prevent Cylinder Head Warping and Damage?

- Regular Cooling System Maintenance: Check coolant levels and quality, flush and replace coolant as recommended, and ensure radiator and water pump function properly.

- Avoid Engine Overheating: Address any overheating issues promptly to prevent damage.

- Use Quality Coolants: Use manufacturer-recommended coolants to prevent corrosion.

- Drive Responsibly: Avoid excessive engine loads and prolonged high RPMs to reduce thermal stress.

Signs You Need Cylinder Head Skimming

- Engine overheating frequently

- White smoke from exhaust (coolant leaking into combustion chamber)

- Loss of coolant with no visible leaks

- Poor engine performance or misfires

- Visible coolant or oil leaks at the head gasket area

Conclusion

Cylinder head skimming is a vital maintenance and repair process that restores the integrity of your engine’s sealing surface. By understanding the causes of cylinder head warping and taking preventive measures, you can avoid costly repairs and maintain optimal engine performance. If you experience symptoms of a warped cylinder head or head gasket failure, consult a professional mechanic immediately to assess the need for cylinder head skimming.

As a leading manufacturer specializing in high-quality cylinder heads and engine parts, XINJIN is committed to providing durable and performance-driven products tailored to meet your engine repair and customization needs. Whether you require cylinder heads, engine blocks, or related components, we offer customized solutions designed for reliability and longevity.

If you’re looking for dependable engine components or want expert advice on cylinder head skimming and related services, don’t hesitate to get in touch with us.