Modern engine tuning is a blend of precision engineering and airflow optimization. Among the most impactful techniques used by performance builders and enthusiasts is cylinder head porting. While often discussed alongside terms like engine porting, the process centers around a very specific component: the cylinder head. In this article, we’ll explore what cylinder head porting is, why it matters, how it’s performed, and whether it’s a worthwhile investment for your build.

What Is Cylinder Head Porting?

Cylinder head porting refers to the reshaping and smoothing of the intake and exhaust ports in the cylinder head to improve airflow. In a stock engine, these ports are often designed with a balance of cost, manufacturability, and emissions compliance in mind. However, they are rarely optimized for maximum performance.

Porting the cylinder head allows air and fuel to flow more freely into the combustion chamber and exhaust gases to exit more efficiently. This leads to more complete combustion, improved volumetric efficiency, and ultimately, increased power.

Why Airflow Matters

Engines are air pumps. The more air an engine can draw in and push out, the more power it can produce. Cylinder head porting improves the efficiency of this airflow process in several ways:

- Reduced turbulence: Smoother ports mean less disruption in airflow.

- Improved velocity: Proper shaping helps maintain high air speed, critical for combustion.

- Balanced flow: Matching port sizes and shapes across cylinders ensures even power delivery.

Methods of Cylinder Head Porting

There are multiple approaches to porting a cylinder head, each with its level of complexity, cost, and effectiveness. Selecting the right method depends on your engine’s configuration, goals, and budget.

1. Hand Porting

Hand porting is a traditional, time-intensive method that involves using carbide burrs, sanding rolls, and die grinders to reshape the ports manually. Skilled builders can tailor the port shapes to specific airflow requirements, achieving highly customized results. When paired with flow bench testing, hand porting can deliver exceptional gains, particularly for unique or non-standard engine builds.

2. CNC Porting

CNC (Computer Numerical Control) porting is a modern alternative that uses automated machinery to shape the ports based on a digital model. The key advantage of CNC porting is consistency—every cylinder head receives identical treatment. This is ideal for high-volume applications, such as spec engines or professional motorsports. CNC porting also allows for intricate geometries that would be difficult to replicate by hand.

3. Pocket Porting

Pocket porting is a more budget-friendly option that focuses on the bowl area beneath the valve seat. It improves airflow where it matters most during low- to mid-lift valve events. Though it doesn’t provide the full benefits of complete porting, it offers meaningful performance gains for street engines and moderate builds.

4. Port Matching

Port matching ensures a seamless transition between the cylinder head and intake/exhaust manifolds. If the ports are misaligned, airflow is disrupted, reducing efficiency. This process involves shaping the edges of the port openings so they align perfectly with the mating components. It is often used in conjunction with other porting methods.

5. Short Side Radius and Long Side Radius Shaping

Within each port, airflow follows a curve as it moves around the short side and long side radius. Reshaping these areas helps direct the flow more efficiently. A well-formed short side radius is especially important for preventing separation and turbulence, which can reduce velocity and volumetric efficiency.

6. Valve Guide and Boss Modifications

The valve guides and the area surrounding them—known as the guide boss—can obstruct airflow if left untouched. By streamlining these features, builders can reduce drag and improve flow. However, care must be taken not to compromise guide stability or cooling.

7. Texturing and Surface Finish Tuning

While smooth surfaces are generally better for exhaust flow, intake ports may benefit from a slightly textured surface to promote fuel-air mixing. Achieving the right surface finish requires experience and varies depending on the application.

The Role of Flow Bench Testing in Cylinder Head Porting

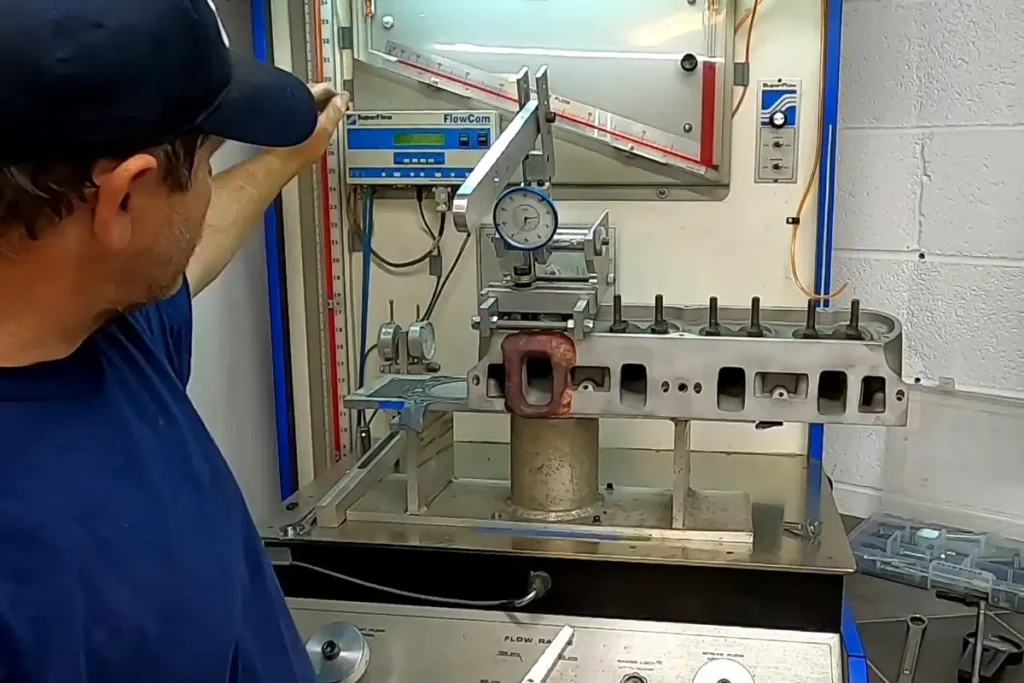

Flow bench testing is a critical part of validating and optimizing cylinder head porting work. A flow bench is a diagnostic device that measures the volume and quality of air that can pass through a cylinder head at various valve lifts. By simulating how air would move through the ports during engine operation, it allows builders to quantify improvements and identify problem areas.

A typical flow bench test records airflow in cubic feet per minute (CFM) and is performed at standardized pressure differentials. The test can highlight whether reshaping a port has increased flow, created turbulence, or altered velocity in a beneficial or harmful way.

Importantly, flow data should not be viewed in isolation. While higher CFM numbers suggest better airflow, the shape of the airflow curve and air velocity at different valve lifts are equally crucial. In some cases, chasing maximum airflow can come at the expense of port velocity, which may reduce performance in low- to mid-range RPMs.

Professional builders often use flow benches iteratively—porting a small section, testing results, then refining the shape—until optimal flow is achieved across all cylinders. For this reason, when selecting a cylinder head porting service, ensuring that flow bench testing is part of their process is a mark of a data-driven and performance-oriented approach.

Common Mistakes to Avoid

Porting a cylinder head is as much an art as it is a science. Here are some common errors that can reduce the effectiveness—or even harm the performance—of the modification:

- Over-porting: Removing too much material can reduce air velocity and hurt low-end torque.

- Inconsistent port shapes: Mismatched ports can lead to uneven airflow between cylinders.

- Rough finishes: Contrary to popular belief, mirror-polishing intake ports can sometimes hurt performance by causing fuel to drop out of suspension.

- Ignoring the valve job: The valve seats and angles must complement the port shape for optimal flow.

When Is Porting Worth It?

Not every engine benefits equally from porting. Factors to consider include:

- Engine type: Naturally aspirated engines benefit more from increased airflow than forced induction ones, which rely on boost.

- RPM range: High-revving engines see more gains from improved airflow.

- Other modifications: Porting yields the best results when combined with cams, headers, and tuned intake systems.

- Budget: Quality porting is not cheap. Weigh the cost against the performance goals for your build.

How to Choose a Cylinder Head Porting Service

If you’re not doing it yourself, choosing the right shop is key. Look for:

- Experience with your engine type

- Flow bench testing capability

- Before-and-after flow data

- Customer reviews and portfolio of past work

Final Thoughts

Cylinder head porting remains one of the most effective methods to unlock hidden horsepower from an internal combustion engine. While it’s often referred to in the broader context of engine porting, the real gains come from refining the airflow paths within the cylinder head.

By improving the breathing efficiency of the engine, you’re enhancing its ability to make power, respond quickly to throttle inputs, and run more efficiently overall. Whether you’re chasing lap times or simply looking for a more spirited drive, a properly ported cylinder head can make all the difference.

Before making the leap, assess your engine setup, budget, and performance goals. With the right planning and execution, cylinder head porting can be a transformative upgrade in any performance build.