What Cylinder Head Porting Involves

Stock cylinder heads are typically designed with a focus on durability, emissions, and manufacturing efficiency rather than optimal airflow. This means that even minor restrictions or turbulence within the port can reduce the amount of air that enters the cylinder. Porting addresses these issues by adjusting the size, shape, and surface finish of the ports to achieve smoother airflow.

How Porting Enhances Engine Performance

Porting can benefit a wide range of engines. Naturally aspirated engines often see significant gains because they rely entirely on atmospheric pressure to draw air into the cylinders. Turbocharged or supercharged engines also benefit, as smoother airflow reduces turbulence and allows forced induction systems to operate more efficiently.

Techniques Used in Cylinder Head Porting

There are several approaches to cylinder head porting, each with its own advantages and considerations.

Hand Porting is a traditional method where skilled technicians use grinders, carbide burrs, and sanding tools to refine the shape of the ports manually. This method allows for precise customization, enabling the port to be tailored to specific engine characteristics, camshaft profiles, and intended performance goals. However, hand porting requires experience and patience, as mistakes can compromise structural integrity or airflow balance.

CNC Porting utilizes computer-controlled milling machines to shape the ports with high precision and consistency. CNC porting is ideal for production runs or for engines where exact replication is necessary. While it provides repeatable results and reduces the risk of human error, CNC machining may lack the nuanced adjustments that hand finishing can provide.

Some high-performance applications combine both techniques: CNC roughing followed by hand finishing. This approach balances efficiency with the fine-tuning capabilities needed for optimal airflow.

Key Areas of Focus During Porting

Not all sections of a cylinder head have the same impact on airflow. Understanding which areas to modify is essential for effective porting.

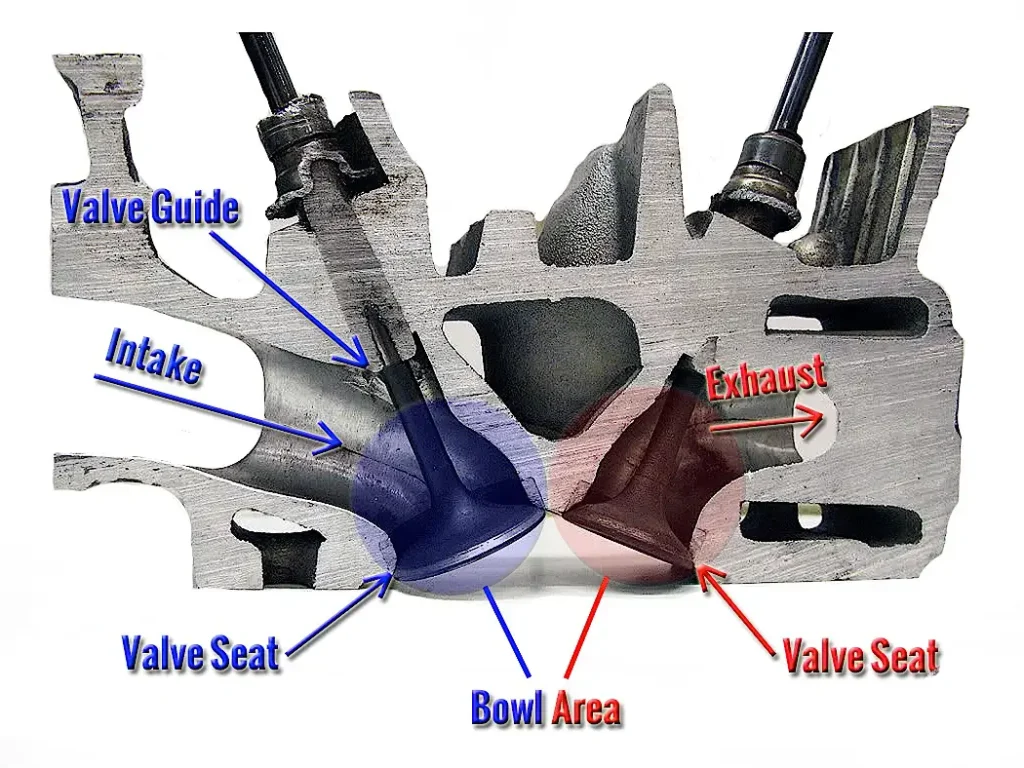

Intake Ports are critical for drawing air into the combustion chamber. Smoothing the walls, eliminating sharp edges, and slightly enlarging the port can improve air velocity and reduce turbulence. Proper intake port design ensures that the air-fuel mixture is evenly distributed to all cylinders, which is particularly important for multi-cylinder engines.

Exhaust Ports allow the engine to expel combustion gases efficiently. Restrictive exhaust ports can create backpressure, limiting performance. Porting the exhaust involves smoothing surfaces, optimizing port shape, and sometimes enlarging the passage to reduce resistance while maintaining proper exhaust velocity.

Valve Seats are the areas where the valves make contact with the cylinder head. Precision in shaping valve seats is vital for proper sealing, which affects compression and combustion efficiency. Porting often includes slight adjustments to the seat angles to enhance airflow without compromising valve function.

Combustion Chambers may also be lightly modified during porting to improve mixture swirl and promote more complete combustion. These changes can lead to smoother engine operation, improved fuel efficiency, and reduced emissions.

Measuring Airflow and Performance

Effective porting requires careful measurement and testing. Airflow benches are commonly used to measure the cubic feet per minute (CFM) of air passing through the ports at various valve lifts. By comparing these readings between stock and ported heads, engineers can quantify improvements and ensure consistency.

Flow dynamics within the port are also important. The goal is not only to increase the volume of air but to maintain laminar flow while minimizing turbulence. Well-ported heads balance these factors to optimize both power and efficiency. Performance gains can then be evaluated through engine dyno testing, which provides data on horsepower, torque, and throttle response.

Risks and Considerations

Porting offers substantial benefits, but it carries certain risks if performed improperly. Over-porting can thin the metal walls of the head, compromising structural integrity. Excessive material removal can also alter the compression ratio, potentially requiring additional tuning of the fuel system or camshaft selection.

Matching porting work to other engine components is crucial. Camshaft profiles, intake manifolds, and exhaust systems all influence how effectively the ported head can perform. A well-executed porting job should consider these interactions to maximize overall engine efficiency without introducing mechanical issues.

Experience and precision tools are essential. Porting is as much an art as it is a science, and even small mistakes can lead to performance losses or engine damage. Consulting experienced professionals or thoroughly studying airflow dynamics is highly recommended for anyone considering cylinder head porting.

Choosing Cylinder Heads for Porting

Not all cylinder heads respond equally well to porting. Material composition, original design, and valve configuration all play roles in determining potential gains. Aftermarket heads designed for high-performance applications often offer better flow potential than standard stock heads. These heads may feature larger ports, higher valve lift capacities, and improved materials that tolerate aggressive porting and higher operating temperatures.

Stock heads can also benefit from porting, but the extent of improvement depends on the initial design limitations. Assessing the airflow characteristics and structural capacity of a head before modification helps determine the best approach and expected performance outcomes.

If you are considering upgrading or replacing your cylinder heads, we offer high-quality new cylinder heads suitable for porting. You can contact us directly to discuss options that match your engine type and performance goals, ensuring a professional and reliable solution.

Conclusion

Cylinder head porting is a precise and effective method for enhancing engine performance. By refining airflow through the intake and exhaust ports, optimizing valve seats, and making subtle adjustments to the combustion chamber, porting can significantly improve power output, torque delivery, and overall engine efficiency. Proper technique, measurement, and attention to detail are essential to avoid structural issues and to maximize performance gains.

Understanding the science behind airflow in the cylinder head empowers enthusiasts and engineers to make informed decisions about engine modifications. Porting is more than cosmetic work; it is a technical process that, when executed correctly, brings measurable benefits to any high-performance or precision-tuned engine.