The cylinder head is a critical component of an internal combustion engine. Mounted on top of the engine block, it closes off the cylinders to form the combustion chamber. More than just a cap, the cylinder head contains intricate pathways and components that control airflow, fuel injection, exhaust, and engine timing. Without it, your engine wouldn’t run.

Understanding how the cylinder head works is essential not just for mechanics and technicians but also for vehicle owners who want to make informed decisions about repairs and upgrades. In this guide, we’ll explain everything you need to know about the cylinder head—its design, functionality, common problems, and its impact on engine performance.

The Function of a Cylinder Head

- Sealing the Combustion Chamber: It provides the top seal over each cylinder, working with the head gasket to contain the intense pressure from combustion.

- Air and Fuel Management: It houses the intake and exhaust ports that allow the air-fuel mixture to enter and burned gases to exit.

- Supports the Valvetrain: It includes valves, camshafts (in overhead camshaft designs), rocker arms, and related parts that control engine timing.

- Houses Spark Plugs and Injectors: In gasoline engines, the head holds the spark plugs. Modern engines may also include fuel injectors in the head.

- Manages Cooling and Lubrication: Internal passages allow coolant and oil to circulate, keeping temperatures under control and parts properly lubricated.

- Structural Mounting Point: The head also serves as a structural base for key engine components, such as the intake and exhaust manifolds, valve cover, and timing gear.

Common Cylinder Head Designs

Side Valve (Flathead)

This older design places the valves in the engine block. The head itself is a simple metal plate with no moving parts. While easy to manufacture, this setup restricts airflow and combustion efficiency.

Overhead Valve (OHV or Pushrod)

Valves are placed in the head, but the camshaft stays in the block. Pushrods and rocker arms transfer motion from the camshaft to the valves. This design is compact and durable but limits high-RPM performance.

Overhead Camshaft (OHC & DOHC)

These modern designs place one or two camshafts in the head itself, offering more precise control of valve timing. Dual overhead camshaft (DOHC) heads are commonly used in high-performance and multivalve engines.

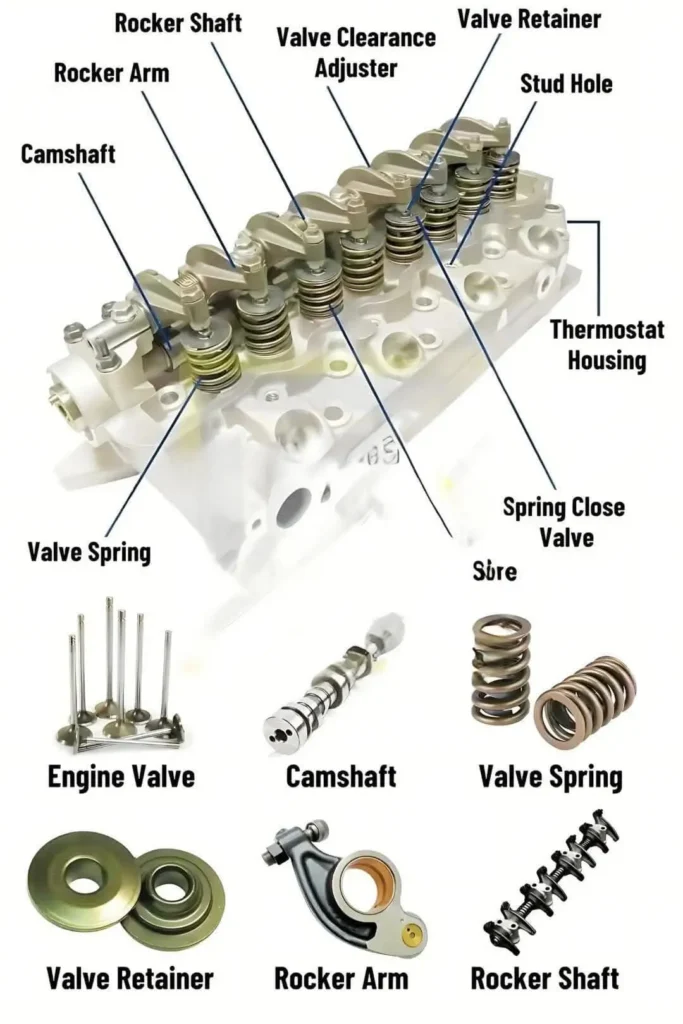

Key Components of a Cylinder Head

Combustion Chamber

This is the space where air and fuel mix and ignite. Its shape directly affects power, efficiency, and emissions. The size and geometry of the chamber also influence compression ratio and detonation resistance.

Valves and Valve Seats

- Intake valves allow the air-fuel mixture into the combustion chamber.

- Exhaust valves let gases exit after combustion. Each valve rests on a valve seat to form a tight seal.

Valve Springs and Retainers

These ensure that valves close properly and maintain correct tension. Weak or broken springs can cause valve float, which leads to loss of power and engine misfires.

Camshaft

Found in OHC and DOHC engines, the camshaft operates valves by pressing against lifters or directly against the valves via cam lobes. Camshaft design (lift, duration, overlap) significantly influences performance characteristics.

Rocker Arms and Rocker Shafts

Used in OHV engines, rocker arms transfer motion from the camshaft (via pushrods) to the valves. Rocker shafts support these arms. Some high-performance setups use roller rockers to reduce friction.

Valve Clearance Adjusters

Also known as hydraulic lifters, these maintain the correct spacing between valves and rocker arms, reducing wear and improving noise control.

Stud Holes and Bolt Passages

These threaded holes allow the head to be bolted securely to the engine block. In performance engines, head studs are used for better strength and even clamping.

Thermostat Housing

Often attached to or integrated into the head, this housing controls coolant flow by regulating when the thermostat opens.

Spark Plug and Fuel Injector Mounts

Spark plugs ignite the air-fuel mixture in gasoline engines. Fuel injectors may also be installed here in direct injection setups. Proper positioning affects combustion efficiency and emissions.

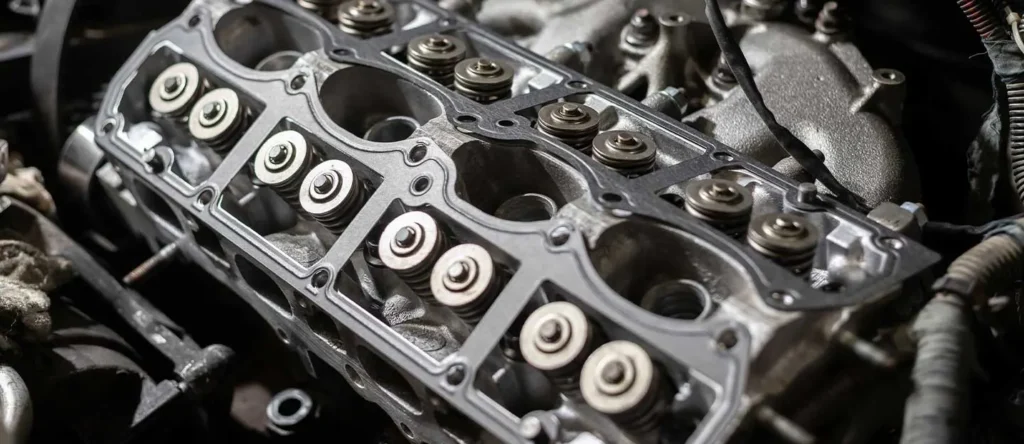

Oil and Coolant Passages

These internal channels help maintain optimal engine temperatures and lubrication. They’re essential for longevity and are often the first areas inspected when diagnosing head cracks or leaks.

Materials and Construction

- Cast Iron: Durable and strong, ideal for heavy-duty or diesel applications.

- Aluminum: Lightweight and dissipates heat quickly, used in most modern gasoline engines.

Common Cylinder Head Problems

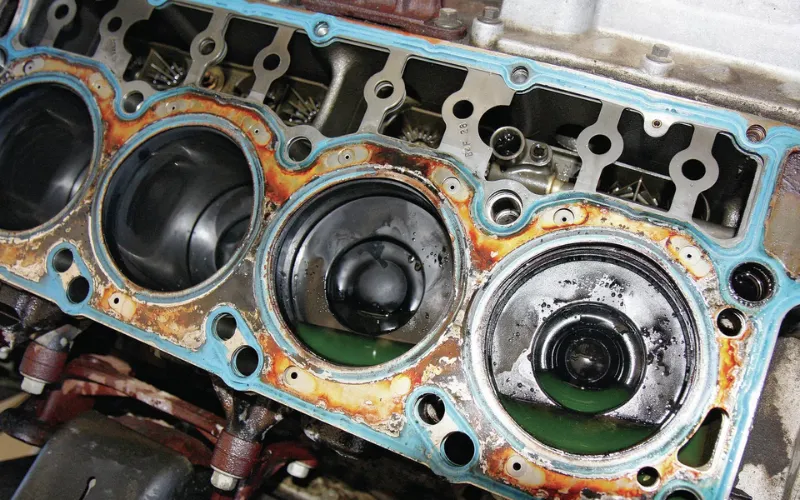

Warping and Cracks

Overheating can warp the head or cause cracks, leading to combustion leaks or coolant loss. Warped heads may require machining to restore a flat surface.

Head Gasket Failure

If the gasket fails, it can allow oil and coolant to mix or leak into the cylinders. Symptoms include white smoke from the exhaust, engine misfires, or overheating.

Valve and Seat Wear

Worn valves or seats reduce compression and engine performance. Poor seating can lead to power loss and increased emissions.

Oil or Coolant Leaks

Carbon Buildup

Deposits on valves and ports can reduce airflow and efficiency. Regular maintenance and high-quality fuel can help prevent excessive buildup.

Cylinder Head Maintenance and Repair

Regular coolant flushes and oil changes help extend head life by preventing buildup and overheating. At signs of failure (e.g., overheating, poor performance, white smoke), the cylinder head should be inspected for cracks or warping. Repairs may involve:

- Surface machining

- Valve replacement or regrinding

- Installing new valve guides or seals

- Pressure testing for cracks

- Replacing the head gasket

For performance applications, cylinder heads may be ported and polished, have larger valves installed, or upgraded to multi-angle valve jobs to improve airflow and combustion.

Cost of Cylinder Head Replacement

Costs vary by vehicle type and engine complexity. Replacing a head on a four-cylinder passenger car may cost $1,000 to $2,500, while performance or diesel engines can cost significantly more. Rebuilt or aftermarket heads may offer savings.

Labor costs can also vary greatly depending on engine layout. In some vehicles, replacing the head requires removal of timing chains, turbochargers, or intake manifolds, which adds to the bill.

Frequently Asked Questions

What causes a cylinder head to fail? Common causes include engine overheating, manufacturing defects, poor coolant maintenance, and extreme operating conditions.

Can you drive with a cracked cylinder head? It’s not recommended. A cracked head can cause coolant loss, misfires, and engine damage. Continued driving may result in a blown head gasket or total engine failure.

How long does a cylinder head last? With proper maintenance, a cylinder head can last the life of the engine. However, heat and stress can eventually cause warping or cracks, especially in high-mileage vehicles.

Is it better to repair or replace a damaged head? It depends on the extent of the damage. Minor warping or wear can often be repaired. Cracks or severe damage usually require replacement.

Can cylinder heads be upgraded for performance? Yes. Upgrades like porting, larger valves, multi-angle valve jobs, and improved materials (e.g., billet aluminum) can significantly boost performance.

Final Thoughts

The cylinder head is one of the most vital components of any internal combustion engine. From sealing the combustion chamber to controlling airflow, timing, and cooling, its design and health directly influence engine performance and reliability. Understanding how it works can help vehicle owners maintain their engines better and make informed repair decisions.

Whether you’re driving a compact commuter car, a diesel truck, or a high-performance sports car, the condition of your cylinder head is key to your engine’s health and your vehicle’s longevity.