What Is a Cylinder Block?

Materials and Manufacturing

Key Components Inside a Cylinder Block

1. Cylinders

Cylinder Lining

2. Crankshaft and Main Bearings

3. Piston Assemblies

Piston Rings

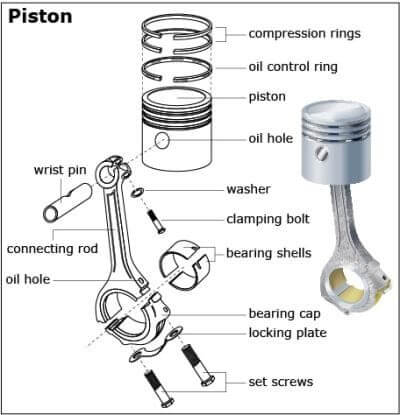

Piston rings are installed around the piston to ensure a tight seal between the piston and the cylinder wall. They prevent combustion gases from escaping into the crankcase while also controlling oil consumption. Most pistons have multiple rings, including compression rings and oil control rings, each performing a distinct function.

Connecting Rod and Wrist Pin

The connecting rod links the piston to the crankshaft. The wrist pin (or gudgeon pin) connects the piston to the small end of the connecting rod, allowing pivoting movement. This connection must withstand extreme forces during the combustion process and maintain precise alignment to ensure smooth engine operation.

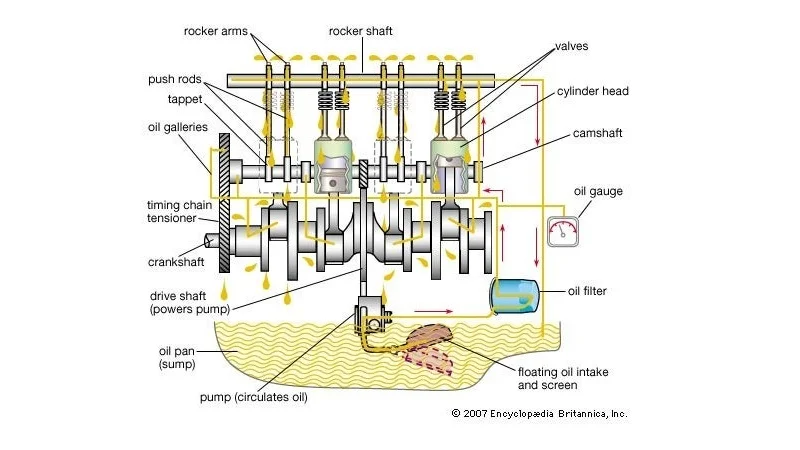

4. Oil Galleries

Oil galleries are internal channels within the cylinder block that deliver lubricating oil to critical components, including the crankshaft, camshaft, and pistons. Proper lubrication reduces friction, prevents overheating, and minimizes wear. The design of oil galleries plays a crucial role in engine reliability, especially under high-performance or heavy-load conditions.

5. Coolant Passages

6. Additional Integrated Components

How Pistons Work Inside the Cylinder Block

- Intake Stroke: The piston moves down the cylinder, drawing in a mixture of air and fuel. The intake valve opens to allow the mixture to enter the combustion chamber.

- Compression Stroke: The piston moves upward, compressing the air-fuel mixture. Compression increases the mixture’s temperature and pressure, preparing it for ignition.

- Power Stroke: The spark plug ignites the compressed mixture, causing rapid combustion. The expanding gases push the piston down, generating mechanical force.

- Exhaust Stroke: The piston moves upward again, expelling burnt gases through the open exhaust valve.

Piston-Cylinder Interaction

The fit between pistons and cylinder walls is crucial. Too tight a fit increases friction and can cause seizure, while too loose a fit reduces compression, leading to power loss and oil consumption. Engineers use precise measurements for piston diameter, cylinder bore, and piston ring thickness to maintain the correct tolerances.

Heat and Stress Management

Pistons experience extreme heat and mechanical stress during combustion. Cylinder blocks help dissipate heat through metal conductivity and integrated coolant passages. Additionally, piston designs often include features such as reinforced crowns, skirts, and pin bosses to handle high loads without deforming.

Common Maintenance Considerations

Maintaining the cylinder block and pistons is critical for engine longevity. Regular oil changes ensure proper lubrication of pistons and crankshaft bearings, while coolant maintenance prevents overheating and cylinder distortion. Engine inspections often include checking cylinder walls for scoring, piston rings for wear, and crankshaft bearings for alignment.

Replacing worn pistons or cylinder liners, when necessary, can restore engine performance and prevent further damage. Proper torque settings during assembly and precise machining are essential to maintain the integrity of the cylinder block-piston system.