The cylinder block is the heart of any internal combustion engine. Serving as the main structure, it houses essential components such as cylinders, coolant passages, and oil galleries, providing the foundation for engine operation. Understanding the various types of cylinder blocks is crucial not only for automotive enthusiasts and engineers but also for those interested in engine maintenance, repair, and performance optimization. This article explores the different types of cylinder blocks, their construction methods, materials, and applications, helping readers gain a clear insight into this critical engine component.

What Is a Cylinder Block?

Before diving into the types, it is important to define what a cylinder block is. Also known as the engine block, it is a robust structure that contains the cylinders where pistons move up and down. The cylinder block supports and aligns many other engine parts, including the crankshaft, camshaft, and cylinder head. It must withstand high internal pressures, heat, and mechanical stresses during engine operation, requiring both strength and precision in manufacturing.

Classification of Cylinder Blocks

1. Based on Material

Cast Iron Cylinder Blocks

Traditionally, most cylinder blocks have been made from cast iron due to its excellent strength, durability, and wear resistance. Cast iron blocks handle high combustion pressures and temperatures well, making them suitable for heavy-duty and industrial engines.

- Advantages: High strength, good wear resistance, excellent vibration damping.

- Disadvantages: Heavy weight leading to reduced fuel efficiency, potential corrosion issues.

Despite the rise of lighter materials, cast iron remains popular for trucks, commercial vehicles, and some passenger cars where durability is prioritized.

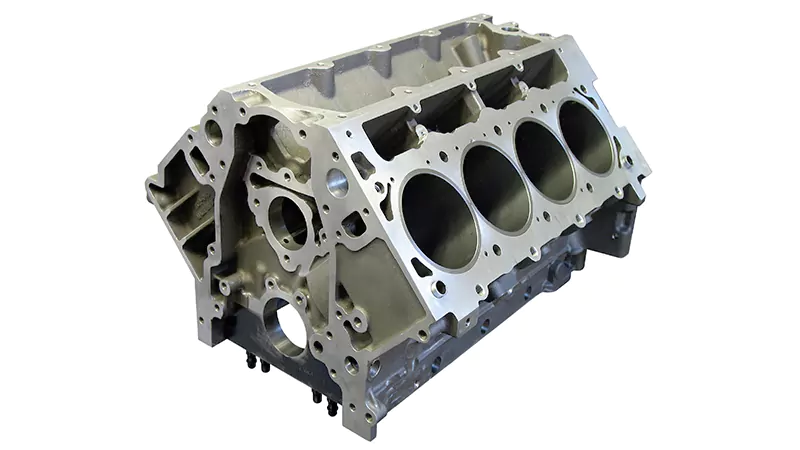

Aluminum Alloy Cylinder Blocks

Aluminum alloy blocks have become increasingly popular in modern engines, particularly in passenger vehicles and high-performance cars. The key benefit is significant weight reduction compared to cast iron, which improves fuel efficiency and handling.

- Advantages: Lightweight, good thermal conductivity for better heat dissipation, corrosion-resistant.

- Disadvantages: Lower strength compared to cast iron, often requires iron or steel cylinder liners to withstand wear.

To compensate for aluminum’s lower wear resistance, manufacturers often insert cast iron or steel cylinder liners or apply special coatings like Nikasil on cylinder walls.

Composite and Other Advanced Materials

Some cutting-edge engines use composite materials or magnesium alloys to further reduce weight and improve thermal management. While still niche and costly, these materials show promise for future engine designs.

2. Based on Construction Method

Monoblock Cylinder Blocks (One-Piece Construction)

A monoblock cylinder block is cast or machined as a single piece, incorporating all cylinders and main bearing supports in one solid structure. This is the most common type in automotive and motorcycle engines.

- Advantages: High structural integrity and rigidity, fewer assembly issues, simpler manufacturing process.

- Applications: Most passenger cars, motorcycles, and light trucks.

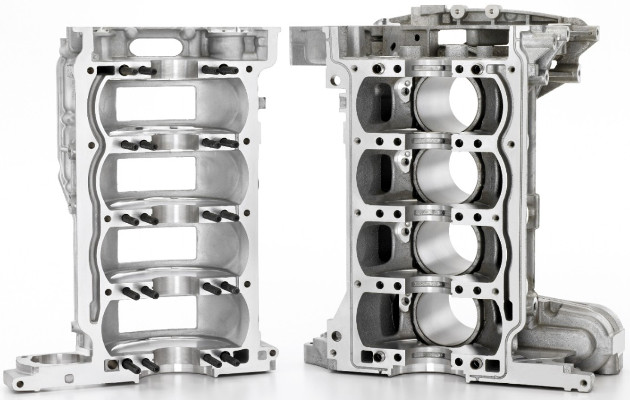

Split Cylinder Blocks (Modular or Sectional Construction)

In some heavy-duty engines, the cylinder block is made in separate sections bolted or fastened together. This design allows easier maintenance and repair, such as replacing damaged sections without scrapping the entire block.

- Advantages: Easier servicing, replacement of damaged parts, can reduce repair costs.

- Disadvantages: Increased manufacturing complexity, potential for leaks or alignment issues at joints.

Such blocks are common in large diesel engines, marine engines, and industrial machinery.

Bedplate Cylinder Blocks

This design combines a separate lower structural member called a bedplate with the upper block containing cylinders. The bedplate improves bottom-end rigidity, reduces vibration, and enhances durability.

- Advantages: Enhanced strength, reduces main bearing deflection, suitable for high-performance or heavy-duty engines.

- Applications: High-performance sports cars, racing engines, large industrial engines.

3. Based on Cylinder Arrangement

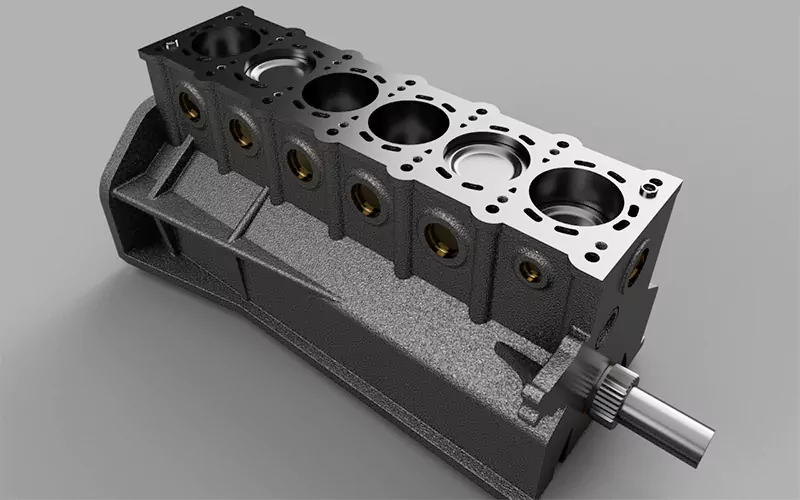

Inline Cylinder Blocks

The simplest configuration, all cylinders are arranged in a straight line. This layout is easy to manufacture and maintain, making it common in four-cylinder and six-cylinder engines.

- Advantages: Compact, simple design, efficient cooling and lubrication.

- Disadvantages: Length can be an issue in larger engines.

V-Type Cylinder Blocks

Cylinders are arranged in two banks set at an angle to form a “V” shape. This layout allows more cylinders in a shorter length, useful for V6, V8, and larger engines.

- Advantages: Compact lengthwise, better balance in some configurations, more power in less space.

- Disadvantages: More complex manufacturing, higher cost.

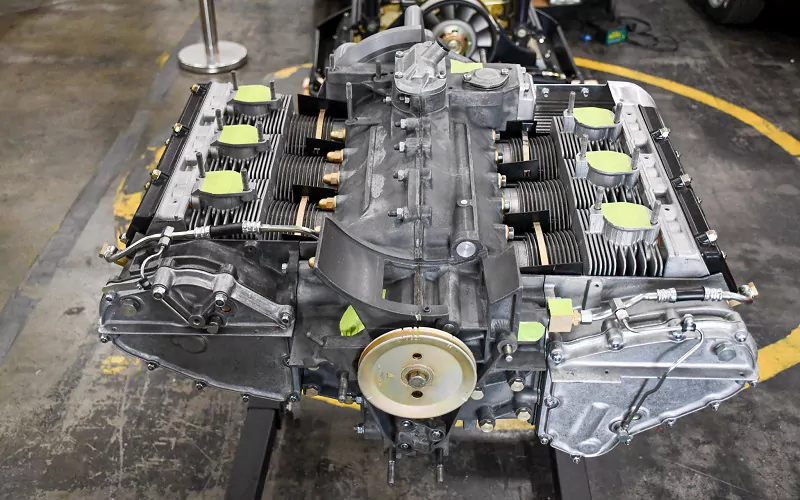

Flat or Boxer Cylinder Blocks

Here, cylinders lie horizontally opposed in two banks. This design lowers the engine’s center of gravity and improves handling in vehicles.

- Advantages: Low center of gravity, smooth operation due to balanced layout.

- Disadvantages: Wide engine size, more complex construction.

Manufacturing Techniques

Cylinder blocks are manufactured primarily through casting and machining processes. The choice of casting (sand casting, die casting, or precision casting) depends on the material and production volume. After casting, the block undergoes extensive machining to ensure precise cylinder bore dimensions, flatness of mating surfaces, and alignment of bearing seats.

Advancements in manufacturing, such as computer numerical control (CNC) machining and 3D printing for prototypes, have improved the accuracy and quality of cylinder blocks.

Factors Influencing the Choice of Cylinder Block Type

Selecting the right cylinder block depends on several important factors that impact engine performance, durability, and cost.

- Engine Application: Heavy-duty vehicles like trucks often use cast iron blocks for their superior strength and ability to handle high stresses and heat. Passenger cars, aiming for better fuel efficiency and lighter weight, typically favor aluminum blocks that offer good thermal conductivity and reduce overall vehicle weight.

- Performance Requirements: High-performance engines demand stronger, more rigid blocks such as bedplate or modular designs. These provide better support to key components under high loads and RPMs, enhancing reliability. For everyday use, simpler monoblock designs are usually sufficient.

- Cost Constraints: Cast iron monoblock blocks are cost-effective for large-scale production due to easier manufacturing. Aluminum and modular blocks tend to be more expensive because of complex casting and assembly processes.

- Maintenance Needs: Modular blocks allow easier repairs by enabling part replacements without discarding the entire block, which benefits commercial applications. However, they add complexity during assembly. Monoblocks, though simpler, can be harder to repair if damaged.

Overall, balancing these factors ensures the chosen cylinder block matches the engine’s purpose, budget, and maintenance capabilities effectively.

Conclusion

The cylinder block plays an indispensable role in engine performance, durability, and efficiency. Understanding the different types — based on materials, construction methods, and cylinder arrangements — provides valuable insight into engine design choices and their implications. Whether it’s the heavy cast iron block of a commercial diesel engine or the lightweight aluminum monoblock in a sports car, each type balances strength, weight, and cost differently to meet specific needs.

By selecting the right cylinder block type, manufacturers and mechanics can optimize engine longevity, performance, and fuel economy, aligning with evolving automotive standards and consumer demands.