At the core of most vehicles on the road today is the internal combustion engine (ICE), a complex machine that transforms chemical energy stored in fuel into mechanical work. Unlike external combustion engines, where fuel is burned outside the engine (e.g., steam engines), ICEs perform combustion inside the cylinders.

The combustion inside an engine involves igniting a precise mixture of fuel and air. This chemical reaction releases energy rapidly, producing expanding gases that push pistons downward. This linear piston movement is then converted into rotational motion by the crankshaft, which ultimately turns the vehicle’s wheels.

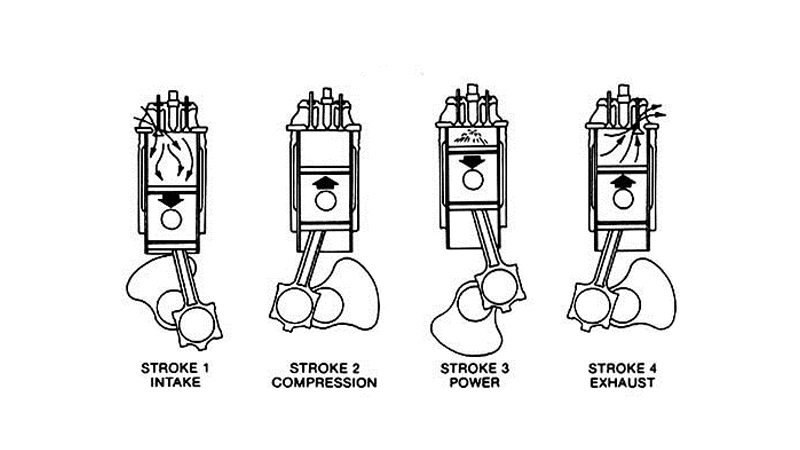

The Four-Stroke Combustion Cycle

The vast majority of modern engines operate on a four-stroke cycle, which consists of the following stages:

- Intake Stroke: The intake valve opens, allowing a mixture of fuel and air to enter the combustion chamber as the piston moves downward, increasing cylinder volume.

- Compression Stroke: Both intake and exhaust valves close. The piston moves upward, compressing the fuel-air mixture to increase pressure and temperature, improving combustion efficiency.

- Power (Combustion) Stroke: At the top of the compression stroke, a spark plug ignites the mixture (in gasoline engines), causing a rapid expansion of gases that force the piston downward, generating mechanical power.

- Exhaust Stroke: The exhaust valve opens, and the piston pushes the burnt gases out of the cylinder as it moves upward.

This cycle repeats thousands of times per minute at varying speeds depending on the engine’s RPM (revolutions per minute).

Diesel Engine Variations

Diesel engines share the same four-stroke cycle but differ in ignition method. They operate on the compression ignition principle, where air is compressed to very high pressures and temperatures, and diesel fuel is injected at the top of the compression stroke, igniting spontaneously without spark plugs. This results in higher torque output and better fuel economy, especially at low RPMs.

Engine Layouts and Cylinder Configurations

Engine layout significantly affects a vehicle’s packaging, weight distribution, and performance characteristics. The two main considerations are how cylinders are arranged physically and how many cylinders are present.

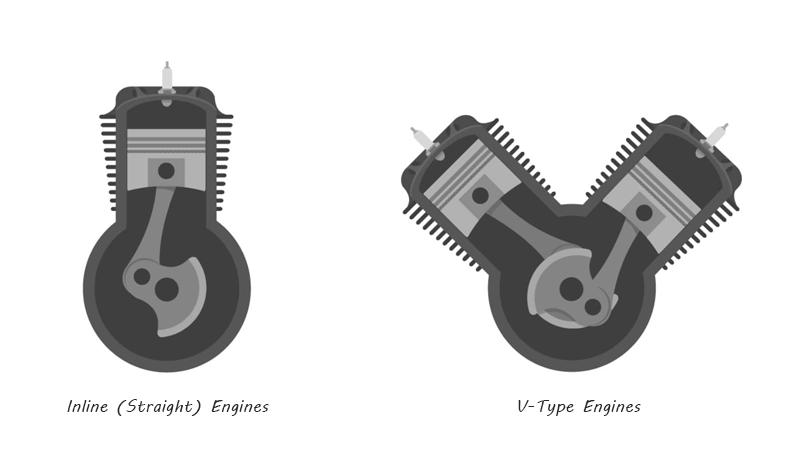

Common Engine Layouts

- Inline (Straight) Engines: Cylinders arranged in a single row, usually vertically oriented. Inline-four engines dominate small to midsize vehicles due to their simplicity, balance, and compact width. Inline-six engines provide exceptional smoothness but require more length.

- V-Type Engines: Cylinders arranged in two banks forming a “V” shape, typically at 60° or 90°. This configuration allows more cylinders in a shorter engine length. V6 and V8 engines are common in performance and luxury cars, providing high power density and smooth operation.

- Flat (Boxer) Engines: Cylinders are horizontally opposed in two banks, lying flat opposite each other. This layout lowers the center of gravity, improving vehicle handling and balance. Subaru and Porsche famously use boxer engines.

- Rotary (Wankel) Engines: Instead of pistons, these engines use a triangular rotor moving inside an epitrochoid chamber. They are compact and lightweight, capable of producing high RPMs and smooth power delivery but tend to have higher fuel consumption and emissions. Mostly used in niche sports cars like the Mazda RX series.

Cylinder Count and Impact on Performance

The number of cylinders in an engine plays a crucial role in power delivery and smoothness:

- Two-Cylinder Engines: Typically found in motorcycles and small cars, they are lightweight and fuel-efficient but limited in power output.

- Three-Cylinder Engines: Popular in small, efficient vehicles. When turbocharged, these engines can provide a balance of power and economy.

- Four-Cylinder Engines: The most common configuration, especially in economy cars and sedans, offering good power and fuel efficiency.

- Six-Cylinder and Higher: Used in high-performance cars and trucks, providing greater horsepower and torque with smoother operation due to more frequent firing intervals.

Enhancing Power - Turbocharging and Supercharging

Modern engines often incorporate forced induction to increase power without enlarging displacement:

- Turbochargers use exhaust gases to spin a turbine compressing intake air, improving efficiency and power but may introduce turbo lag.

- Superchargers are mechanically driven by the engine and provide immediate boost at the cost of some efficiency.

Both methods increase the oxygen supply, allowing more fuel combustion and higher output.

Conclusion

Understanding how different engine types and configurations work is essential for making informed vehicle choices. Whether you prioritize power, fuel economy, emissions, or maintenance, knowing the basics helps tailor your decision to your driving needs.

At XINJIN, we specialize in manufacturing precision-engineered cylinder heads, engine blocks, and related parts designed to maximize your vehicle’s performance and reliability. Whether you need OEM replacements or custom solutions, our products meet the highest standards for durability and fitment.

Looking for expert advice or a quote on your next engine component? Contact XINJIN today and let our experienced team help you find the perfect parts tailored to your application.