If you peek under the hood of most modern cars, you’ll notice a common feature: four valves per cylinder. It’s so standard now that it’s easy to take it for granted. But this design didn’t appear overnight. The journey from two valves to four, and even the occasional five, is a story of engineering driven by the quest for more power, better fuel efficiency, and cleaner emissions. Understanding multi-valve technology is essential for anyone who cares about how an engine performs or wants to make informed decisions when sourcing engine components.

How Multi-Valve Engines Work?

At its core, an engine is about controlling airflow. A four-stroke engine needs a precise balance of intake and exhaust. The intake valves let the air-fuel mixture in, and the exhaust valves let spent gases out. Better airflow means the engine can burn fuel more completely, produce more power, and use less fuel.

Think of it this way: a single large intake valve in a two-valve engine can only let in so much air. Split that valve into two smaller ones, and suddenly you have more total flow. Engineers calculate that with the same valve lift, two smaller valves can allow roughly 50 percent more air into the cylinder than one large valve of the same diameter. This simple tweak has a big impact, letting the engine breathe more freely and perform better at high speeds.

Beyond airflow, valve placement is key. Multi-valve designs allow the spark plug to sit near the center of the chamber, promoting smoother and faster combustion. Lighter valves reduce stress on the camshaft, letting engines rev higher without compromising durability.

From Two Valves to Three Valves

Two-valve engines dominated cars and motorcycles for decades. One intake, one exhaust—it’s simple, easy to manufacture, and reliable. Low-speed torque was strong, which suited the driving conditions of the time. But as cars got faster and emissions regulations tighter, the limits of two-valve engines became clear.

The three-valve layout appeared as a compromise. Typically, this meant two intake valves and one exhaust valve, offering better airflow without making the engine too complicated or expensive. Some motorcycles still use this setup to balance performance and cost. In cars, three-valve engines were briefly explored in the early 2000s, but they never caught on because four-valve designs offered a clearer advantage.

Four-Valve Engines

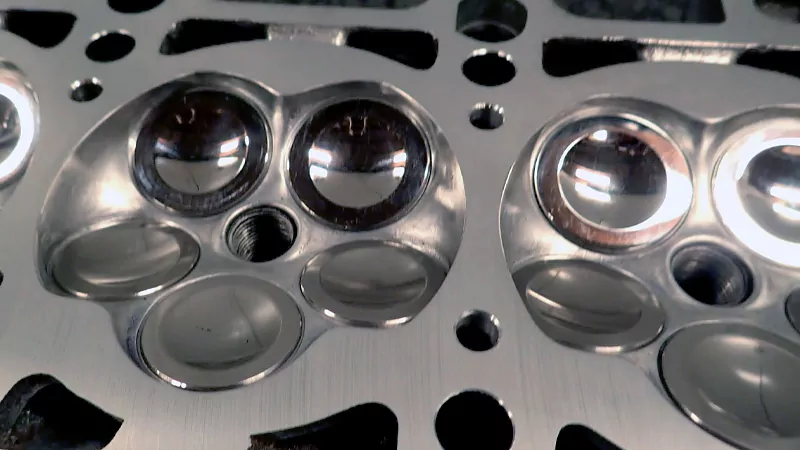

Today, four valves per cylinder is the rule rather than the exception. Two intake and two exhaust valves give engines more breathing room, improving both power and efficiency. This layout also allows engineers to optimize combustion, especially when combined with technologies like variable valve timing (VVT), direct fuel injection, and turbocharging.

The benefits are tangible. Engines can rev higher thanks to lighter valves, airflow is more efficient, and fuel burns more completely. Four-valve designs help engines stay cooler under load and give engineers flexibility in cylinder head design. Even small engines benefit, producing more power per liter while remaining fuel efficient. It’s no wonder that from city cars to sports models, four-valve engines dominate the market.

Five-Valve Engines

In the 1990s, some manufacturers experimented with five valves per cylinder—usually three intake and two exhaust—to push airflow even further. High-performance motorcycles and some sports cars used this configuration. The idea was promising, but the reality didn’t live up to expectations. The extra complexity increased costs and maintenance demands, while performance gains were modest. Today, five-valve engines are mostly a historical footnote, with four valves per cylinder remaining the practical standard.

Advantages of Multi-Valve Engines

Multi-valve engines provide several advantages beyond simple airflow improvements. Smaller, lighter valves reduce mechanical stress and allow higher engine speeds, resulting in increased specific output. Better valve placement enables more efficient combustion and allows for advanced technologies such as variable valve timing, direct injection, and turbocharging. Four-valve layouts also improve cooling of the cylinder head, helping engines maintain performance under sustained load and reducing the risk of overheating.

In addition to performance gains, multi-valve engines often achieve better fuel efficiency and lower emissions. Even in smaller engines, these benefits contribute to smoother operation and more reliable performance, showing that multi-valve designs are advantageous across a wide range of vehicles.

Why Two-Valve Engines Are Rare Today

Two-valve engines are no longer common in cars, and for good reason. Their limited airflow constrains high-speed power, and combustion is less efficient. Even though they were once praised for strong low-speed torque, modern four-valve engines with VVT can surpass them in every aspect. Two-valve engines now mainly exist in older vehicles, certain small motorcycles, or very low-cost applications where simplicity and reliability are more important than performance.

Conclusion

The evolution from two to four valves per cylinder reflects the engineering drive to meet real-world performance, efficiency, and emission demands. While two-valve engines have historical significance and three-valve setups appear occasionally in motorcycles, four-valve designs are the practical standard for modern automotive applications.

For manufacturers, understanding multi-valve technology is crucial when designing or sourcing engine components. Cylinder heads and engine blocks must accommodate optimal valve arrangements, combustion efficiency, and heat management.

We are a professional manufacturer specializing in engine components, including cylinder heads and engine blocks. Our expertise in multi-valve design and precision manufacturing ensures components that meet the highest standards of performance and durability. Contact us to discuss how our solutions can support your engine development and production needs.