Visual Inspection

Exterior Surfaces and Casting

Start by examining the block’s exterior. Look closely at the casting for any cracks, dents, or scratches. Mounting points and corners are particularly vulnerable. Even hairline cracks can expand once the engine is under pressure. Rust or corrosion, especially on iron blocks, should also raise a red flag, as it may indicate poor storage or previous exposure to moisture. Aluminum blocks tend to resist corrosion better, but they still deserve a careful eye.

Signs of Previous Work or Damage

Check for any signs that the block has been worked on before. Evidence of welding, poorly applied sealant, or uneven paint can hint at past repairs or modifications. Take your time, using a flashlight to illuminate hard-to-see areas. Small imperfections that you might initially overlook can reveal larger problems lurking beneath the surface.

Cleanliness and Contamination

Cylinder Bores

Cylinder bores are the heart of the block. Inspect them closely for scratches, scoring, or metal shavings. A bore light or magnifying glass can help reveal subtle imperfections. The interior surface should be smooth and free of contaminants that could affect piston fit or ring performance.

Oil and Coolant Passages

Inspect all fluid passages for blockages, debris, or corrosion. Clean, unobstructed oil and coolant channels are essential for proper engine operation and longevity. Any restriction can lead to overheating, poor lubrication, or catastrophic failure.

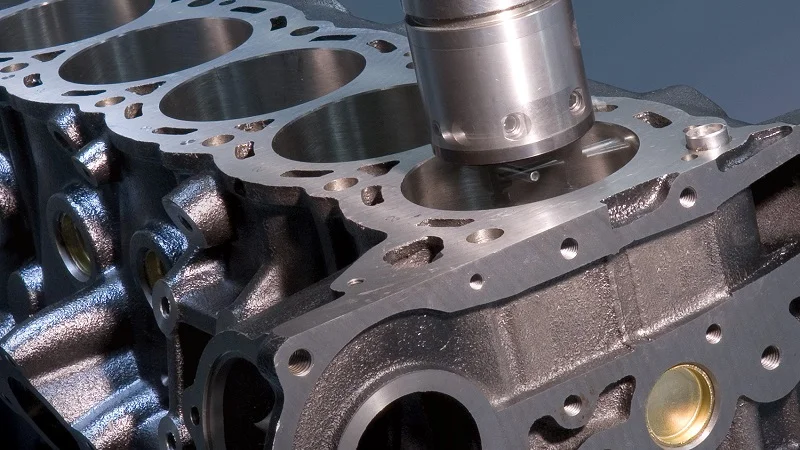

Deck Surface and Threads

Examine the deck surface where the cylinder head mounts. It should be smooth, flat, and free from nicks or leftover gasket material. Threads for head bolts and other fasteners should be clean and undamaged. Cross-threaded or stripped threads can compromise assembly and sealing.

Cylinder Bore Measurement

Checking Diameter and Roundness

Precision in cylinder bore dimensions is critical. Using a dial bore gauge, measure the cylinder diameter at multiple points along the bore. Check for taper or out-of-round conditions. Cylinders that deviate from manufacturer specifications can lead to poor piston fit, compression loss, or increased wear.

Comparison with Specifications

Compare your measurements to official tolerances for the engine model. Cylinders outside these tolerances may require boring or honing before assembly, adding time and cost to the project.

Main Bearing Surfaces

Visual Inspection

The main bearings support the crankshaft and experience significant stress. Look for scoring, discoloration, or signs of overheating. Misaligned main bores can cause premature bearing wear or crankshaft issues.

Alignment and Torque Marks

Check the alignment of the main caps and bearing surfaces. Proper torque application during assembly ensures correct bearing preload, which is vital for engine longevity. Witness marks or torque marks can help verify that assembly procedures were followed correctly.

Cylinder Head and Deck Considerations

Deck Flatness

The deck surface must be perfectly flat to ensure a proper seal with the cylinder head. Use a straight edge and feeler gauge to check for warping or unevenness.

Bolt Holes and Threads

Threads for cylinder head bolts should be intact and clean. Damaged threads or cross-threading can cause improper torque and lead to leaks or compression loss.

Valve Seat Areas

For blocks with integrated valve seats, inspect the surfaces to ensure they are smooth and undamaged. Imperfections in this area can compromise sealing and reduce engine efficiency.

Pressure and Leak Testing

Water Jacket Pressure Test

Leakdown Test

For assembled engines, a leakdown test helps determine whether cylinders maintain proper compression. It can also reveal issues with piston rings, valves, or head gaskets that might otherwise go unnoticed.

Bottom End Inspection

Crankshaft and Connecting Rods

The bottom end houses the crankshaft and connecting rods, components that undergo extreme stress. Remove the oil pan to inspect these parts carefully. Look for scratches, scoring, or other signs of wear.

Metal Debris and Contamination

Presence of metal shavings or unusual deposits can indicate previous damage or inadequate maintenance. Catching these issues early prevents potential engine failure.

Material Quality and Build

Cast Iron vs Aluminum

Cast iron blocks offer durability and wear resistance, while aluminum blocks provide lighter weight and better heat dissipation. Both require precision casting and machining for optimal performance.

Machining and Casting Integrity

Examine the block for casting defects such as porosity or bubbles. Critical surfaces should be smooth, flat, and precisely aligned. Poor casting or machining can compromise engine reliability and lifespan.

Final Verification

Documentation and Authenticity

Check casting numbers, part numbers, and specifications to ensure the block is genuine and matches your engine requirements. Documentation from the manufacturer or rebuilder provides assurance of quality.

Included Components and Reputable Sources

Verify that all advertised components, such as freeze plugs or bearing inserts, are included. Purchasing from a trusted supplier reduces the risk of receiving a substandard engine block.

Conclusion

For those looking to purchase a high-quality engine or engine block, XinJin Auto Parts offers a range of premium products backed by professional service. Our commitment to quality ensures that every engine you receive meets strict standards for performance and durability. Contact us today to find the right engine solution for your needs and experience the reliability that comes with working with XinJin Auto Parts.