Choosing the right cylinder head can make or break your engine’s performance. Whether you’re rebuilding a high-performance engine, upgrading an older vehicle, or selecting components for a custom build, the cylinder head plays a pivotal role in airflow, compression, and overall engine efficiency.

But with so many materials, port configurations, valve sizes, and compatibility concerns, it can be overwhelming to know where to begin. This guide will walk you through the key factors you need to consider when choosing a cylinder head, helping you make an informed decision that suits your performance goals and budget.

What Does a Cylinder Head Do?

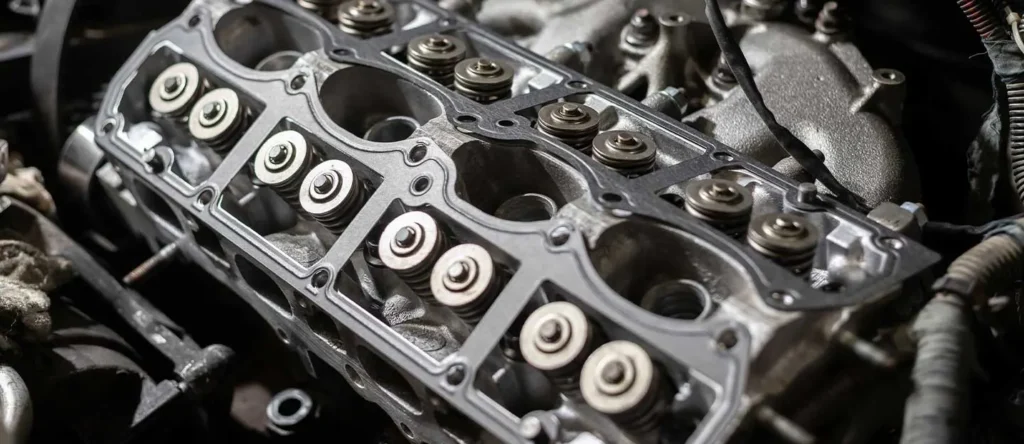

Before diving into the selection process, it’s essential to understand the function of the cylinder head. Mounted on top of the engine block, the cylinder head seals the combustion chamber and manages the intake and exhaust airflow. It houses critical components such as valves, spark plugs, and in some configurations, the camshaft(s).

The right cylinder head can significantly improve horsepower, torque, fuel efficiency, and even emissions. Conversely, a poorly matched cylinder head can create bottlenecks in performance or lead to engine failure.

10 Key Steps to Choosing the Right Cylinder Head

Selecting the perfect cylinder head for your engine isn’t just about grabbing the most expensive or best-reviewed option. It involves careful evaluation of your engine’s needs, performance goals, and component compatibility. Below are ten essential steps that will guide you through the decision-making process with confidence.

1. Define Your Engine Goals

Your engine’s intended use should drive your decision-making process. Are you building for:

- Street driving and daily reliability?

- Off-road torque and durability?

- Track racing and high-rev horsepower?

- Heavy-duty towing or commercial use?

Different applications require different characteristics in a cylinder head. A street car may benefit from better fuel atomization and low-end torque, while a race car needs high airflow and high-RPM stability.

Start by clearly defining your goal. This will help determine the best combination of materials, port shapes, valve sizes, and combustion chamber volume.

2. Know Your Engine Platform

Compatibility is non-negotiable. A cylinder head must match your engine block in terms of bolt pattern, coolant passage alignment, valve train geometry, and combustion chamber design.

Be sure to gather the following information before shopping for a new head:

- Engine make, model, and displacement

- Year of manufacture

- Camshaft configuration (OHV, SOHC, DOHC)

- Bore and stroke size

- Piston type (flat, dome, dished)

Matching these specs ensures proper installation and optimal performance.

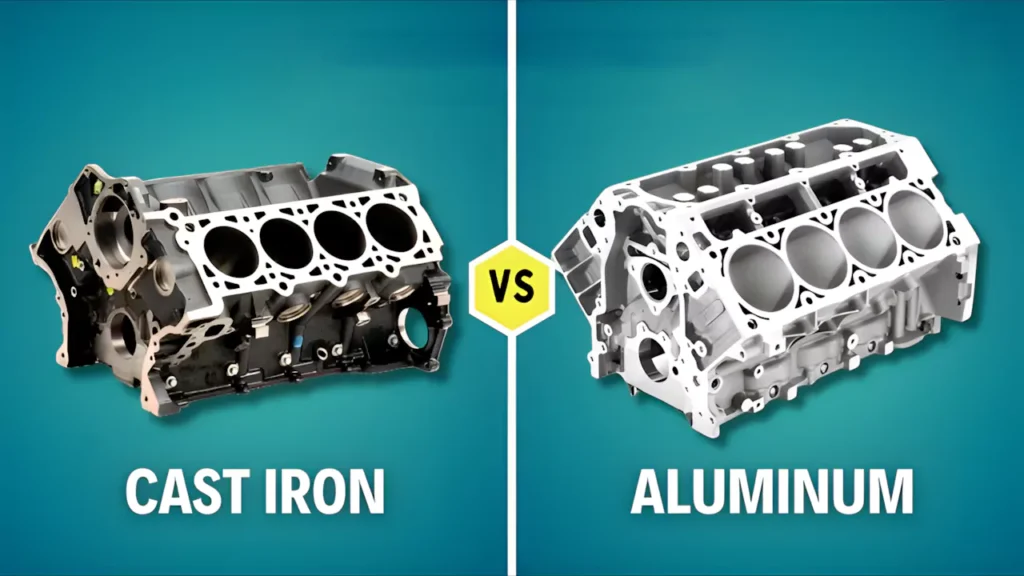

3. Material: Cast Iron vs. Aluminum

Most cylinder heads are made from either cast iron or aluminum. Each has its pros and cons depending on your priorities.

Cast Iron Heads

- Advantages: More durable, resistant to warping, typically less expensive.

- Best for: Heavy-duty applications, budget builds, or restorations.

Aluminum Heads

- Advantages: Lighter weight, better heat dissipation, improved performance potential.

- Best for: Performance builds, racing, and modern engine upgrades.

4. Port and Valve Design

Airflow is king when it comes to engine performance, and this is where cylinder heads make a huge difference. Port size, shape, and valve diameter directly impact how efficiently the engine breathes.

Port Types:

- Stock or Small Port: Best for street use and low-RPM torque.

- High-Flow or CNC Ported: Ideal for high-performance and racing applications.

- Raised Ports: Often used in drag racing for high-RPM gains.

Valve Size:

Larger valves generally allow more air and fuel into the cylinder, boosting horsepower at higher RPMs. However, larger valves may reduce low-end torque and require changes to piston clearance or camshaft timing.

5. Combustion Chamber Size and Compression Ratio

The size of the combustion chamber affects the engine’s compression ratio—a key factor in power output and fuel type compatibility.

- Smaller chambers raise the compression ratio, boosting efficiency and power.

- Larger chambers lower the compression ratio, often necessary for forced induction or low-octane fuel.

Make sure the combustion chamber volume works in harmony with your pistons and head gasket to achieve the ideal compression ratio for your application.

6. Valve Train Compatibility

Cylinder heads must work with the existing or planned valve train system. Consider:

- Rocker arm ratio

- Pushrod length

- Valve spring seat pressure

- Camshaft lift and duration

- Retainers and locks

Mismatched components can lead to valve float, piston interference, or camshaft failure.

7. Intake and Exhaust Manifold Fitment

The cylinder head’s port layout and bolt pattern must match your intake and exhaust manifolds. While some aftermarket heads are designed for stock manifolds, high-performance heads may require custom or upgraded components.

8. Cooling and Oil Flow Considerations

Efficient cooling and oil flow are essential for engine longevity, especially under high-stress conditions.

Look for features like:

- High-capacity coolant passages

- Improved oil drainback design

- Compatibility with upgraded radiators or oil coolers

9. Budget and Brand Reputation

While it’s tempting to chase top-tier performance parts, always factor in your total project budget. Cylinder heads vary widely in price, from a few hundred to several thousand dollars.

When choosing a brand or supplier, consider:

- Reputation in the market

- Warranty and after-sales support

- Availability of technical assistance

- Online reviews and user feedback

10. Consider Fully Assembled vs. Bare Heads

You can purchase cylinder heads as:

- Bare heads: No valves, springs, or hardware—ideal if you’re reusing or customizing your valve train.

- Assembled heads: Come ready to install with all necessary components—great for time savings and compatibility assurance.

Final Thoughts

Choosing the right cylinder head is a crucial step in any engine project. It requires balancing performance goals, engine compatibility, material properties, and budget constraints. By understanding the factors outlined above, you’ll be better equipped to select a cylinder head that enhances your engine’s reliability, efficiency, and power.

Whether you’re an experienced builder or a first-time enthusiast, take the time to research, ask questions, and consult with professionals or suppliers. The right decision today can save you countless hours—and dollars—down the road.