Engine oil is often described as the lifeblood of a vehicle’s engine, and for good reason. Every internal combustion engine relies on this fluid not only to reduce friction between moving parts but also to maintain proper temperature, prevent corrosion, and ensure the engine performs at its best. Without engine oil, a car would quickly overheat and suffer severe wear, leading to expensive repairs or even total engine failure. Understanding how engine oil works, how it flows through an engine, and when it needs to be replaced along with the oil filter is essential for every vehicle owner who wants to protect their investment.

The Role and Functions of Engine Oil

The primary function of engine oil is lubrication. Inside an engine, pistons, crankshafts, camshafts, and various bearings move at extremely high speeds, often thousands of times per minute. Engine oil forms a thin protective film between these metal surfaces, reducing friction and preventing direct metal-to-metal contact. This lubrication is vital not only for the longevity of engine components but also for the engine’s efficiency, as less energy is wasted overcoming internal friction.

Beyond lubrication, engine oil also acts as a cooling agent. While the vehicle’s coolant system manages the overall engine temperature, there are areas within the engine—such as the piston skirts and bearing surfaces—where coolant cannot reach directly. Circulating oil absorbs some of this heat and carries it away, helping maintain a stable operating temperature and preventing hotspots that can damage engine components.

Another critical role of engine oil is cleaning. Combustion produces soot, carbon deposits, and tiny metallic particles from engine wear. Oil contains detergents and dispersants that suspend these contaminants, preventing them from adhering to critical surfaces. As the oil passes through the oil filter, these particles are trapped, keeping the engine clean and maintaining optimal performance.

Engine oil also contributes to sealing. The oil film around the piston rings and cylinder walls improves compression and reduces blow-by gases. This sealing function is essential for efficient combustion and consistent engine power. Additionally, engine oil protects against corrosion. Combustion byproducts can be acidic, and condensation inside the engine can lead to rust. Oil contains additives that neutralize acids and prevent rust, extending the lifespan of engine parts.

How Engine Oil Flows Through the Engine

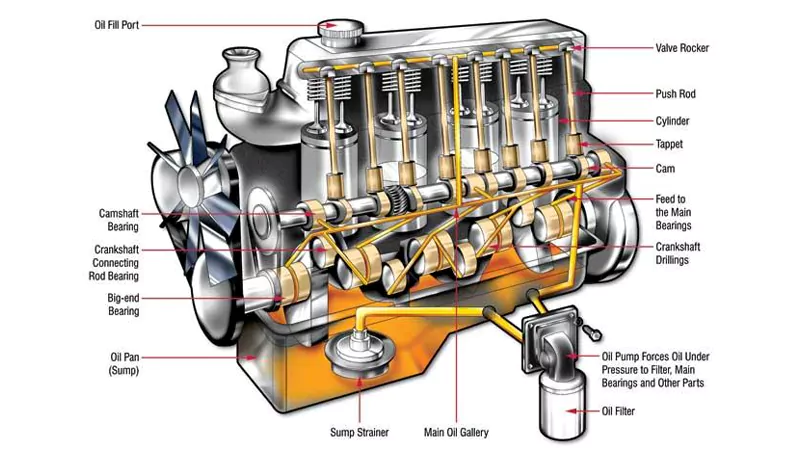

Understanding how oil circulates within the engine is key to appreciating its role. Engine oil starts in the oil pan, also called the sump, located at the bottom of the engine. From this reservoir, the oil pump draws the fluid and pressurizes it, sending it through passages known as oil galleries to reach various components.

The oil first flows to the crankshaft and connecting rod bearings, lubricating the moving parts as they rotate. From there, it moves to the camshaft, timing gears, and valve train, ensuring all high-friction surfaces receive proper lubrication. During this circulation, oil absorbs heat from the engine components and carries contaminants to the oil filter. The oil filter removes particles, preventing them from causing damage or accumulating as sludge. After completing its journey, the oil returns to the sump to be recirculated, forming a continuous loop that ensures protection at all times.

Oil viscosity and temperature are critical in this process. Thicker oil provides better lubrication but may not flow as easily at low temperatures, while thinner oil flows quickly but may offer less protection under extreme pressure. This balance is why selecting the right type of oil—whether synthetic or conventional—is crucial for engine performance.

Oil Types and Their Impact

Conventional oil is derived from refined crude oil and typically requires more frequent changes. It works well for standard driving conditions but can break down faster under high stress or extreme temperatures. Synthetic oil, on the other hand, is engineered to provide consistent viscosity and superior thermal stability. It can better resist breakdown, offer improved lubrication, and often extends the intervals between oil changes.

The choice between synthetic and conventional oil depends on your vehicle, driving habits, and manufacturer recommendations. Many modern engines, especially high-performance or turbocharged engines, benefit from synthetic oils due to their enhanced protective properties.

Oil and Oil Filter Replacement Intervals

Regular oil changes are essential for maintaining engine health. For vehicles using conventional oil, the typical replacement interval is every 3,000 to 5,000 miles, or roughly every three to six months. Synthetic oil allows longer intervals, usually between 7,500 and 10,000 miles, or six to twelve months. Regardless of oil type, the oil filter should be replaced at every oil change. The filter plays a crucial role in trapping contaminants, and a clogged filter can reduce oil flow, leading to inadequate lubrication and potential engine damage.

Signs that an oil change may be needed sooner include dark or dirty oil, unusual engine noises such as knocking, the oil warning light on the dashboard, or excessive exhaust smoke. Ignoring these signs can result in sludge buildup, overheating, and severe engine wear. Regular maintenance protects the engine, preserves efficiency, and prevents costly repairs.

Conclusion

Engine oil plays a critical role in lubrication, cooling, cleaning, sealing, and protecting against corrosion. Choosing the right type of oil and following recommended maintenance schedules ensures your engine operates reliably and lasts longer.

At XINJIN, we manufacture high-quality complete engines, engine blocks, cylinder heads, and related components. Whether you are looking for OEM-standard engines or custom solutions for your project, we provide professional guidance and direct factory support. Contact us today to discuss your engine requirements and secure high-performance components directly from the manufacturer.