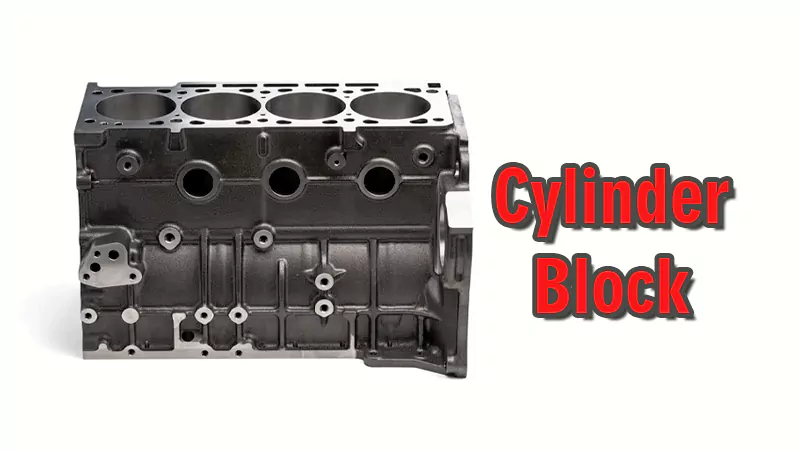

The engine assembly begins with the engine block, also referred to as the cylinder block. The engine block is the largest component of the engine and serves as the foundational structure that houses critical engine components.

Materials and Construction

The engine block is typically made from cast iron or cast aluminium alloys. Cast iron has been the predominant material for over a century, valued for its strength and durability. Early engines used individual cylinders connected by networks of brass pipes for oil and coolant circulation, which were difficult to mass-produce and expensive. The advent of cast engine blocks allowed the integration of cylinders, oil passages, and main crankshaft saddles, significantly reducing production costs and enabling mass production.

In the last 20 to 30 years, aluminium alloy blocks have become increasingly common. Aluminium is significantly lighter than cast iron, reducing engine weight by approximately 30%, which benefits fuel efficiency and performance. Billet aluminium blocks, machined from a solid aluminium block, are rare and primarily used in racing or restoration due to their high cost.

Cylinder Design

The primary function of the engine block is to house the cylinders, where pistons move up and down. In cast iron blocks, cylinders are machined directly into the block. In aluminium alloy blocks, cylinder liners may be inserted to provide durable wear surfaces, or chemical coatings such as Nicosil may be applied. These liners provide the hardness necessary to withstand piston movement, as aluminium is softer than cast iron.

The cylinder surface is critical for minimizing friction and maintaining proper lubrication. A fine crosshatch pattern is created during honing to form small diamond-shaped grooves that retain oil. This ensures that piston rings run on a thin film of oil rather than contacting the cylinder wall directly.

Deck Surface and Cylinder Head Interface

The top surface of the engine block, known as the deck, mates with the cylinder head and is separated by a gasket. The deck must be perfectly flat to maintain a gas-tight seal under the high pressure of combustion. While cylinder heads may warp and require resurfacing, the deck of the block is typically more rigid and less prone to deformation.

Inline engines usually have a single deck, whereas V-shaped or W-shaped engines have multiple decks, each corresponding to a cylinder head. When machining is required, all decks must be processed to the same height.

Lubrication System

Oil galleries run throughout the engine block, supplying lubricant to main bearings, journals, and other critical components. Oil is pumped from the sump into the main gallery, then directed to the cylinder head to lubricate the camshafts and valve train. Some engines include oil jets that spray lubricant onto the underside of pistons, lubricating the wrist pins and cylinder walls while aiding cooling. Proper lubrication ensures reduced wear and maintains clearances between moving components.

Crankcase and Main Caps

The lower portion of the engine block, known as the crankcase, houses the crankshaft. Main caps secure the crankshaft within the saddles and contain bearings. Each main cap is machined to fit its specific saddle and must be returned to its original position during assembly. The oil pan or sump mounts to the underside of the block and contains engine oil, sealed with a gasket or instant adhesive.

Core Plugs

Core plugs, often referred to as freeze plugs or expansion plugs, seal openings left by the casting process. They allow removal of sand from the internal mold during production. While commonly believed to prevent engine damage from frozen coolant, their primary purpose is manufacturing-related. Core plugs are made of thin metal and may corrode, potentially causing leaks, but they are relatively easy to replace.

Engine Mounts and Accessory Bosses

The engine block provides secure mounting points for attachment to the vehicle chassis, often with rubber isolators to reduce vibration. Machined bosses allow installation of accessories such as water pumps, alternators, and air conditioning compressors. These mounts and bosses provide structural support for both the engine and its auxiliary components.

Coolant System Integration

The engine block contains cavities for coolant circulation to regulate cylinder temperature. Proper cooling prevents pre-ignition, reduces wear from thermal expansion, and maintains clearances between pistons and cylinder walls. Coolant typically flows from the lower block to the cylinder head and returns via the radiator. Effective system design avoids air pockets, ensuring complete coolant drainage and efficient thermal management.

Conclusion

The engine block is the foundation of every internal combustion engine, providing structural strength, housing critical components, and ensuring proper lubrication and cooling. From cylinder design to oil galleries, core plugs, and mounting points, each feature is carefully engineered to optimize performance and durability.

As a dedicated engine manufacturer, we design and produce high-quality engine blocks that meet the rigorous demands of modern vehicles, ensuring reliability, efficiency, and long-lasting performance. Contact us today to learn more.