The engine is the beating heart of your car—a complex machine that transforms fuel into the power that moves your vehicle. Whether you’re a complete beginner or someone with a bit of mechanical know-how, understanding the engine’s internal structure can deepen your appreciation for how your car works and help you maintain it better.

In this article, we’ll take an in-depth look at the key components inside a typical internal combustion engine, explain their functions, and reveal how they all work together to generate the power that drives your wheels.

What Is an Engine and How Does It Work?

The Engine Defined

An engine, specifically an internal combustion engine (ICE), is a device that converts the chemical energy stored in fuel into mechanical energy. This mechanical energy then powers your car. Most cars use gasoline or diesel engines. Inside the engine, fuel mixes with air, burns (combusts), and the resulting energy pushes parts inside the engine to create motion.

Think of the engine as your car’s heart and muscles—it pumps energy and converts it into movement.

The Four-Stroke Cycle

Most car engines operate using a four-stroke cycle, which repeats thousands of times per minute:

- Intake Stroke: The piston moves down, the intake valve opens, and a mixture of air and fuel enters the cylinder.

- Compression Stroke: The intake and exhaust valves close, and the piston moves up, compressing the air-fuel mixture to a high pressure and temperature.

- Power Stroke: The spark plug ignites the compressed mixture, causing an explosion that forces the piston down, generating power.

- Exhaust Stroke: The exhaust valve opens, and the piston moves up, pushing out the burnt gases.

This cycle constantly repeats, driving the crankshaft and creating the power your car needs to move.

Key Internal Engine Components and Their Functions

1. Cylinder Block

The cylinder block is the engine’s main structure, usually made from cast iron or aluminum alloy. It houses the cylinders—precise, smooth chambers where the pistons move up and down.

The block must be strong enough to withstand the high pressures and temperatures from combustion, while also dissipating heat efficiently.

2. Cylinder Head

The cylinder head sits on top of the cylinder block, sealing the cylinders and forming the combustion chamber. It contains essential parts like intake and exhaust valves, spark plugs, and fuel injectors. Its design influences airflow and combustion efficiency and must withstand extreme heat and pressure.

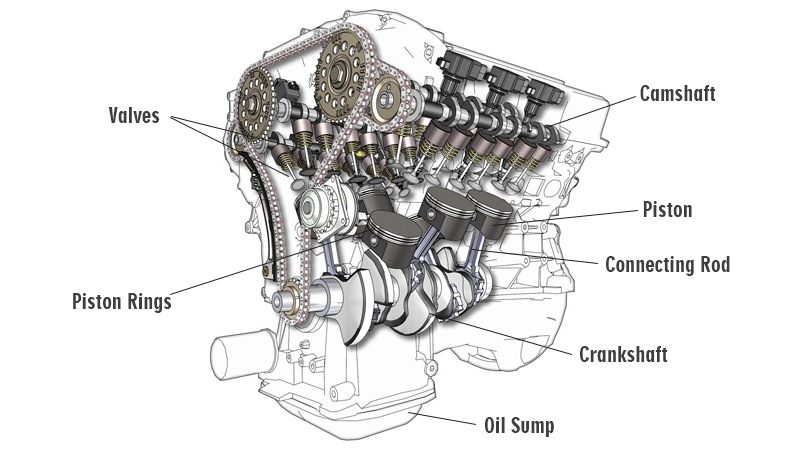

3. Pistons

Pistons are cylindrical components that move up and down inside the cylinders. They take the force generated by burning fuel and transfer it to the connecting rods. Made from lightweight, heat-resistant materials like aluminum alloys, pistons have piston rings that ensure a tight seal between the piston and cylinder wall to prevent gas leakage and control oil consumption.

4. Connecting Rods

Connecting rods link pistons to the crankshaft. They convert the piston’s linear (up and down) motion into rotational motion. They need to be very strong and durable to handle the enormous forces during combustion.

5. Crankshaft

The crankshaft converts the pistons’ up-and-down movement into rotational motion that ultimately powers the wheels. It has counterweights to balance the engine and reduce vibrations.

6. Valvetrain (Valve Mechanism)

The valvetrain controls the opening and closing of the intake and exhaust valves, regulating airflow into and out of the cylinders. Key components include:

- Valves: Intake valves allow air/fuel mixture in; exhaust valves let combustion gases out.

- Valve springs: Keep valves closed when they need to be sealed.

- Rocker arms and lifters: Transfer motion from the camshaft to the valves.

7. Camshaft

The camshaft has lobes (cams) that push the valves open at precisely the right time. It rotates at half the speed of the crankshaft to maintain correct valve timing.

8. Spark Plugs

Spark plugs ignite the compressed air-fuel mixture, creating the explosion that drives the piston down. The timing and condition of spark plugs heavily affect engine performance and efficiency.

9. Lubrication System

The engine contains hundreds of moving parts rubbing against each other. The lubrication system pumps oil to coat these parts, reducing friction and preventing wear. It also helps cool engine components and keeps them clean by suspending contaminants.

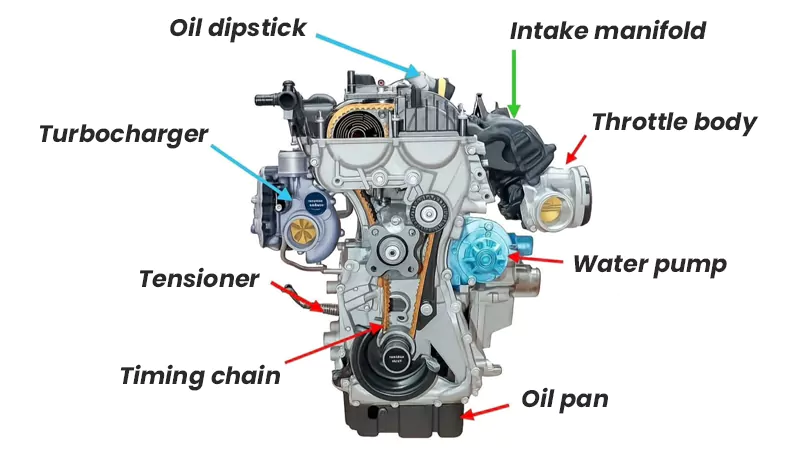

10. Cooling System

Burning fuel generates massive heat. The cooling system circulates coolant (usually a mixture of water and antifreeze) to absorb heat and prevent the engine from overheating. It consists of components like the water pump, radiator, thermostat, and hoses.

Supporting Systems Inside the Engine

1. Intake System

The intake system delivers clean air to the cylinders:

- Air filter: Removes dust and debris from the air.

- Intake manifold: Distributes air evenly to each cylinder.

- Throttle body: Controls how much air enters the engine, responding to your accelerator pedal input.

2. Exhaust System

The exhaust system removes harmful gases produced during combustion:

- Exhaust manifold: Collects gases from cylinders.

- Catalytic converter: Converts toxic gases into less harmful emissions.

- Muffler: Reduces engine noise.

3. Turbocharger

A turbocharger uses exhaust gas energy to spin a turbine that compresses incoming air, packing more oxygen into the cylinders.

More oxygen allows burning more fuel, increasing engine power without increasing size.

Synchronizing the Engine Timing Systems

For the engine to run smoothly, the crankshaft and camshaft must be perfectly synchronized. This ensures valves open and close at exactly the right moments relative to piston position.

1. Timing Belt or Chain

The timing belt (made of rubber) or timing chain (metal) connects the crankshaft to the camshaft, maintaining precise timing. Chains tend to last longer but are noisier; belts are quieter but need regular replacement.ition.

2. Tensioners

Tensioners keep the timing belt or chain taut, preventing slippage or skipping teeth, which could cause serious engine damage.

How Energy Flows Inside the Engine?

The engine converts fuel into motion through a series of energy transformations:

- Fuel and air mix and enter the cylinder.

- The piston compresses this mixture.

- The spark plug ignites it, causing an explosion.

- The explosion pushes the piston down, generating mechanical force.

- The connecting rod and crankshaft convert this force into rotational energy.

- Exhaust gases exit, and the cycle repeats.

This seamless cycle occurs thousands of times per minute, powering your car smoothly and reliably.

Conclusion

Your engine’s intricate parts work under extreme stress. Regular maintenance—like checking oil levels, replacing oil and filters, inspecting belts, and monitoring coolant—ensures longevity and prevents breakdowns.

An engine may seem like a mysterious mechanical beast, but its inner workings follow precise engineering and careful design. Each component—from the cylinders and pistons to the valves and turbocharger—plays a critical role in turning fuel into forward motion.

As a trusted manufacturer of precision engine parts, we provide reliable, durable, and expertly engineered components to keep your engines performing at their best. Contact us today to learn more about our product range, custom solutions, and how we can support your business needs.