The engine block is the heart of every internal combustion engine. Often overshadowed by more glamorous components like turbochargers or cylinder heads, the engine block plays a quiet yet essential role in keeping vehicles running smoothly. Whether you’re a vehicle owner, a mechanic, or an automotive parts supplier, understanding the design, function, and significance of the engine block is vital.

This article provides a comprehensive overview of engine blocks—what they are, how they work, their key components, types, materials, common issues, and how modern innovations are reshaping their design and performance.

What Is an Engine Block?

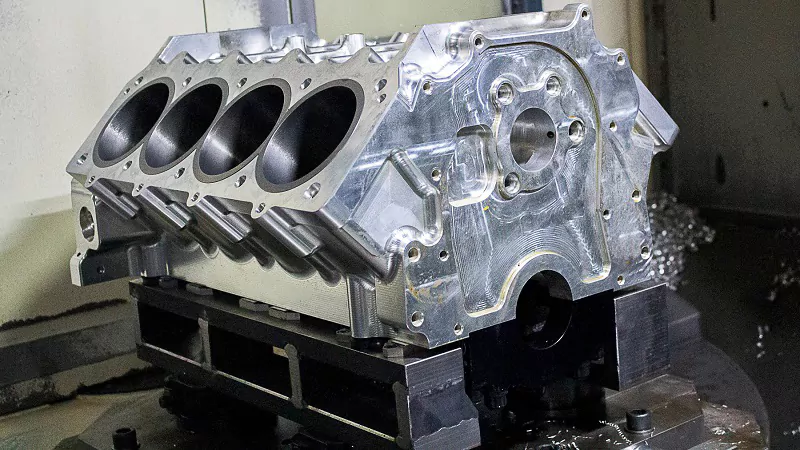

The engine block, also referred to as the cylinder block, is the main structure of an engine. It houses critical internal components such as the cylinders, pistons, crankshaft, and often the camshaft. Acting as the primary structural element, it holds everything in place and allows for the conversion of fuel into mechanical energy.

Typically cast from iron or aluminum alloy, the engine block must endure extreme heat and pressure while maintaining structural integrity and dimensional precision.

Core Functions of an Engine Block

An engine block isn’t merely a casing that holds engine components—it’s the structural and functional backbone of the internal combustion engine. Its design directly influences durability, power output, cooling efficiency, and even fuel economy. Let’s explore each of its fundamental roles in more detail:

1. Cylinder Housing

- Fewer cylinders (e.g., 3 or 4) offer better fuel economy and lower emissions, commonly found in compact cars.

- More cylinders (e.g., 6 or 8) provide smoother operation, greater torque, and higher power output, suitable for performance or heavy-duty vehicles.

2. Structural Support

The engine block serves as the load-bearing frame for the entire engine assembly. It must absorb and redistribute the immense forces generated by rapid combustion events, rotating crankshafts, and reciprocating pistons—all while maintaining dimensional stability.

Structural rigidity is essential for:

- Maintaining crankshaft alignment, reducing wear on bearings and journals.

- Preventing vibrations that could damage accessories or compromise engine mounts.

- Ensuring sealing surfaces remain flat, especially between the block and the cylinder head.

Modern engine blocks often feature cross-bolted main caps, reinforced bulkheads, and deep-skirted designs to increase strength and reduce flex during high-load operation. High-performance engines may also use girdles or bedplates to further stabilize the lower end of the block.

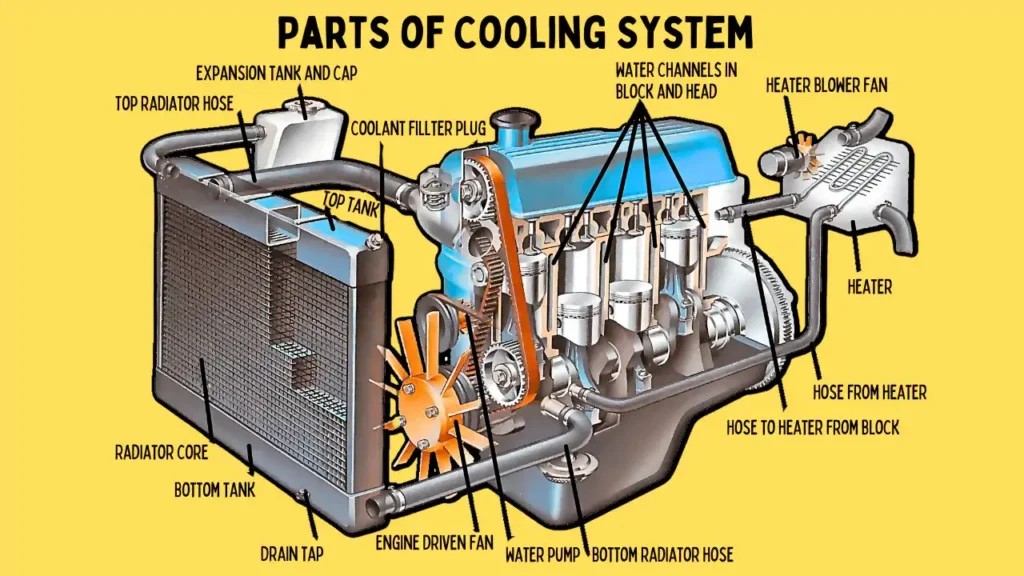

3. Coolant and Oil Circulation

One of the most underappreciated roles of the engine block is its role in thermal management and lubrication. Within the casting of the block are intricate coolant jackets and oil passages designed to maintain optimal operating conditions.

- Coolant jackets surround the cylinder walls and combustion zones to draw away excess heat. This helps prevent detonation, thermal expansion, and component warping.

- Oil galleries channel motor oil to crucial areas such as main bearings, piston cooling jets, and camshaft journals. These internal routes must be free from casting flaws or obstructions to ensure consistent lubrication.

The balance between cooling and oiling design is delicate: overly aggressive coolant flow may reduce thermal efficiency, while restricted oil galleries can lead to catastrophic bearing failure. Advanced manufacturing techniques like CNC-machined galleries and precision-drilled cooling circuits are now standard in high-performance or OEM-grade blocks.

4. Integration with Other Systems

The engine block acts as the central chassis to which most of the engine’s systems are connected. Every surface, bolt hole, and gasket interface must be precisely machined to accommodate mating parts like:

- Cylinder head(s): Where intake, exhaust, and combustion processes are finalized.

- Oil pan: Seals the bottom of the block and stores the engine’s oil supply.

- Timing system: Includes gears or chains that synchronize camshaft and crankshaft motion.

- Ancillary components: Such as the alternator, air conditioning compressor, and water pump.

Proper dimensional accuracy is critical. Misalignment can lead to oil leaks, timing issues, head gasket failure, or excessive noise and vibration. This integration is where OEM tolerances and quality control in aftermarket blocks become a significant concern for engine builders and automotive technicians.

Key Components Found in an Engine Block

The engine block houses and interfaces with a wide range of components. Though it’s typically a single casting, it includes various internal features and machined surfaces that make it a highly sophisticated piece of engineering.

Cylinder Bores

These vertical chambers guide the pistons during their stroke. They must be:

- Perfectly round and smooth, often finished with honing crosshatch patterns to aid oil retention.

- Coated or lined in aluminum blocks (e.g., with Nikasil or iron liners) to reduce wear.

- Consistently spaced to prevent vibration or uneven wear.

Modern performance engines often feature plasma-sprayed liners or cylinder sleeves to increase durability.

Crankcase

Located at the bottom of the block, the crankcase houses the crankshaft, which converts piston motion into rotational torque. It is subject to:

- High stress, particularly at main journal locations.

- Oil splash and windage, which affect crankshaft drag and oil control.

- Pressure fluctuations, often mitigated by a PCV (positive crankcase ventilation) system.

Some blocks incorporate windage trays or baffles in the crankcase design to reduce oil aeration at high RPMs.

Main Bearings

These are inserted between the block and the crankshaft, typically secured with bearing caps. They must:

- Handle continuous rotational loads and shock forces.

- Be precisely aligned to prevent crankshaft misfire or vibration.

- Maintain tight oil clearances, often within microns.

Oil Galleries

These are precision-drilled channels that distribute pressurized oil from the pump to critical moving parts. Any block defect (e.g., debris, casting flash) can restrict flow and lead to premature wear or failure.

Coolant Jackets

Surrounding the cylinders and combustion zones, these internal cavities carry coolant throughout the engine. Efficient cooling helps:

- Maintain combustion efficiency.

- Protect against overheating.

- Prolong the life of head gaskets, pistons, and valves.

Deck Surface

This top surface must be absolutely flat to ensure a proper seal with the cylinder head. Even minor warping can lead to:

- Head gasket failure

- Coolant-oil mixing

- Compression loss

Precision resurfacing may be required during rebuilds.

Materials: Cast Iron vs. Aluminum

Material selection for an engine block is one of the most influential decisions in both OEM and aftermarket design. Each option presents trade-offs in weight, thermal behavior, durability, and cost.

Cast Iron Engine Blocks

Cast iron has been the industry standard for over a century. It’s still widely used in heavy-duty vehicles, diesel applications, and budget-conscious manufacturing.

Advantages:

- Exceptional strength under thermal and mechanical stress.

- Excellent wear resistance, especially in the cylinder walls.

- Superior vibration damping, which improves engine NVH (noise, vibration, harshness) characteristics.

- Naturally resistant to cylinder bore distortion, making them suitable for high-compression applications.

Disadvantages:

- Significantly heavier, affecting vehicle balance and fuel economy.

- Slower heat dissipation, which can lead to hot spots if not well managed.

- Susceptible to rust, requiring proper coolant and anti-corrosion care.

Cast iron blocks are often preferred in trucks, industrial engines, and high-performance racing applications where strength outweighs the need for lightweight construction.

Aluminum Engine Blocks

Aluminum alloy blocks have become standard in passenger cars and light trucks, particularly since manufacturers are under pressure to reduce emissions and improve efficiency.

Advantages:

- Lightweight, often 40–60% lighter than iron, improving vehicle dynamics.

- Faster heat transfer, which can help reduce knock and improve thermal management.

- Corrosion-resistant, especially with proper coolant maintenance.

Challenges:

- Lower strength than iron, requiring structural reinforcements.

- Cylinder walls often need iron sleeves or plasma coatings to prevent rapid wear.

- More prone to warping under extreme heat or load.

Manufacturers often use open-deck aluminum blocks in economy vehicles and semi-closed or closed deck designs in performance models to balance weight savings with durability.

Types of Engine Blocks

Engine blocks are categorized based on their design and intended use. Here are the most common types:

1. Open Deck Block

In this design, the upper part of the cylinder bores is not supported by the surrounding block material. It allows better coolant flow and is often used in daily drivers.

2. Closed Deck Block

A more rigid design where the area around the top of the cylinders is reinforced. This setup is favored in high-performance or turbocharged engines due to its superior strength.

3. Semi-Closed Deck Block

A hybrid between open and closed deck designs, offering a balance of cooling and strength. It is common in OEM high-performance engines.

Common Engine Block Problems

Despite their durability, engine blocks can experience a range of issues—especially in high-mileage or poorly maintained engines.

1. Cracks

Usually caused by overheating or physical stress. Cracks can lead to coolant leaks, oil contamination, or loss of compression.

2. Warping

Excessive heat can warp the deck surface or cylinder bores, leading to head gasket failure or uneven wear.

3. Corrosion

Particularly in iron blocks without proper coolant maintenance, corrosion can compromise coolant jackets and lead to internal leaks.

4. Cylinder Wear

Over time, the inner surfaces of the cylinders may wear out, leading to oil burning, loss of power, or reduced compression.

5. Casting Defects

Occasionally, factory defects in the block’s casting can manifest as weak points, especially under high-performance conditions.

Inspection and Maintenance Tips

Routine inspection of the engine block is essential for long-term reliability:

- Monitor coolant and oil levels.

- Watch for white smoke (possible coolant leak) or blue smoke (oil burning).

- Check for visible cracks or oil leaks around the block.

- Listen for unusual knocking or rattling sounds.

During rebuilds, machinists often check the block for flatness, bore taper, and alignment of bearing journals. Honing or boring may be required to restore performance.

The Engine Block in Rebuilding and Aftermarket Upgrades

Engine blocks are often reused or upgraded during engine rebuilds. There are several aftermarket options:

- Bare Blocks: Provide the basic structure, allowing builders to choose their own internals.

- Short Blocks: Include the block, crankshaft, pistons, and rods—ideal for moderate performance builds.

- Long Blocks: Add cylinder heads and valvetrain—often a bolt-in solution for complete engine replacement.

High-performance aftermarket blocks often feature reinforced webbing, increased bore sizes, or compatibility with stroker kits.

Modern Innovations in Engine Block Design

As automotive technology advances, so too does engine block design. Recent trends include:

1. Lightweight Materials

Some manufacturers are experimenting with magnesium alloys or composite materials to reduce engine weight further without sacrificing strength.

2. Precision Casting

Advanced casting techniques, such as lost foam and sand core printing, allow for more intricate coolant passages and optimized structural geometry.

3. Thermal Management Enhancements

Modern blocks often integrate thermal barriers, variable coolant routing, and improved heat transfer features to support turbocharged or hybrid engines.

4. Digital Simulation and Testing

Engineers now use computer modeling and finite element analysis (FEA) to design blocks that balance strength, weight, and heat resistance even before prototyping.

Why the Engine Block Still Matters

While automotive headlines focus on electric drivetrains and autonomous systems, the internal combustion engine remains dominant—especially in commercial, industrial, and enthusiast markets. The engine block, as the cornerstone of this system, continues to evolve but retains its essential purpose.

Even as the industry embraces electrification, hybrid vehicles and performance applications still rely heavily on robust, efficient engine blocks. For businesses in the aftermarket parts sector, understanding the nuances of block design, compatibility, and performance is crucial for meeting customer expectations.

Final Thoughts

The engine block is far more than a piece of metal—it’s a carefully engineered foundation that brings together strength, precision, and endurance. Whether cast in iron or aluminum, open or closed deck, stock or modified, the engine block remains a critical component in nearly every internal combustion engine on the road today.

For professionals, enthusiasts, and suppliers alike, a deeper understanding of engine blocks translates into better service, smarter purchasing, and longer-lasting performance.