When most people think about engines, they imagine the roar of a powerful V8, the turbo whistle of a performance car, or the efficiency of a modern diesel. But very few pause to think about the one component that makes all of this possible: the engine block.

The engine block may not look glamorous. At first glance, it’s just a large piece of cast iron or aluminum with holes and passages. Yet, it’s no exaggeration to say the block is the foundation of power. Without it, there would be no place to mount cylinders, no structure to hold the crankshaft, and no way to channel heat and oil.

Whether you’re driving a compact car through city streets, hauling goods with a heavy-duty truck, or racing on a circuit, the reliability and strength of your vehicle’s engine depend largely on the quality of its engine block.

Why the Engine Block Matters?

The engine block is the skeleton of the internal combustion engine. It houses the cylinders where combustion takes place, provides seating for the crankshaft and bearings, and offers the mounting points for critical accessories. Every other major engine component, from the pistons to the cylinder head, depends on the block for alignment and stability.

Combustion temperatures can exceed 2,000°C (3,600°F). Without cooling, the engine would destroy itself in seconds. The engine block solves this by incorporating coolant passages (water jackets). These channels allow coolant to flow around the cylinders, absorbing heat and carrying it away to the radiator.

Friction is the enemy of performance. To minimize it, the engine block is designed with oil galleries—small passages that route oil under pressure to bearings, pistons, and moving components. This lubrication reduces wear, prevents overheating, and ensures smooth operation.

The material and geometry of an engine block affect everything from fuel efficiency to horsepower output. A lighter aluminum engine block improves handling and acceleration, while a durable cast iron engine block withstands the punishing torque of heavy-duty applications.

Because it endures enormous stress—high pressure from combustion, vibration, and constant thermal cycling—the engine block’s strength and precision determine how long an engine lasts. Reinforced blocks are especially important in turbocharged, racing, or commercial engines.

Engine Block Materials

Not all engine blocks are created equal. Their performance characteristics depend heavily on the materials used.

Cast Iron Engine Block

For decades, cast iron has been the go-to material. It is:

- Strong and durable, ideal for high torque applications.

- Cost-effective to produce and machine.

- Excellent at wear resistance, making it long-lasting.

Aluminum Engine Block

As automakers chase lighter, more efficient vehicles, aluminum engine blocks have become the industry standard in many passenger cars. Benefits include:

- Lightweight, reducing vehicle mass and improving fuel economy.

- Excellent heat dissipation, allowing engines to run cooler.

- Adaptability, often reinforced with iron liners for durability.

Components of the Engine Block

The engine block isn’t a single piece of metal; it’s a carefully engineered structure with multiple integrated components:

Cylinders

The cylinders are the heart of combustion, where fuel and air ignite to push pistons up and down. Cylinder arrangement (inline, V-shaped, or flat) directly affects engine smoothness, compactness, and power delivery.

Deck Surface

This is the flat top of the engine block where the cylinder head is mounted. Precision here is critical—the surface must be perfectly machined to ensure a tight seal with the head gasket. Any imperfection can cause leaks, compression loss, or overheating.

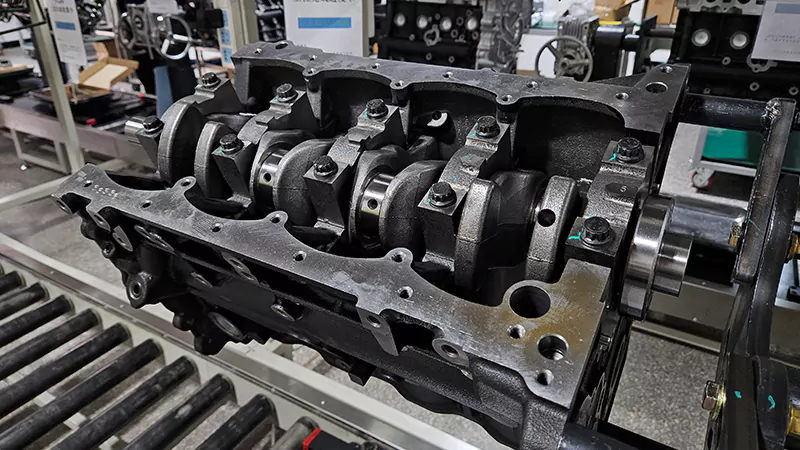

Crankcase

Located in the lower part of the block, the crankcase houses the crankshaft. It must be strong enough to withstand rotational forces while allowing lubrication and ventilation.

Main Bearing Caps

These are heavy-duty covers that clamp the crankshaft in place, preventing misalignment. In performance engines, reinforced bearing caps are often used to handle extra stress.

Coolant Passages (Water Jackets)

Running through the block, these passages act as cooling channels, allowing coolant to circulate around the cylinders and absorb excess heat.

Oil Galleries

Machined passages in the block that distribute oil under pressure. Without them, bearings and pistons would seize from friction.

Core Plugs (Freeze Plugs)

Small round plugs that seal off casting holes. They also provide a safety function—expanding coolant in freezing conditions can push them out, preventing the block from cracking.

Accessory and Timing Mounts

The block includes mounting points for timing chains or belts, oil pumps, and other accessories, ensuring everything is in proper alignment.

Engine Block Designs & Layouts

Engine blocks aren’t one-size-fits-all. Their design influences performance, packaging, and application.

- Inline (Straight) Engines: Cylinders are arranged in a single row. Compact and efficient, often used in smaller cars and trucks.

- V-Type Engines: Cylinders are split into two banks arranged in a “V” shape. Popular in performance and heavy-duty vehicles for their balance of power and compactness.

- Flat (Boxer) Engines: Cylinders lay flat, opposite each other. Known for a low center of gravity, used in brands like Subaru and Porsche.

Another important distinction is wet liner vs. dry liner blocks:

- Wet liners are removable sleeves directly in contact with coolant, making maintenance easier.

- Dry liners are pressed into the block, offering more rigidity but less service flexibility.

Conclusion

The engine block may appear simple, but it’s the soul of the engine. It supports, cools, lubricates, and protects every moving part. A weak block means a weak engine, but a well-engineered block ensures reliability, performance, and durability for years to come.

Are you looking for a reliable engine block manufacturer and supplier? At XINJIN, we specialize in precision-engineered engine blocks, cylinder heads, differentials, and drivetrain components.

- OEM & Wholesale Supply – trusted by partners worldwide.

- High-strength cast iron and lightweight aluminum solutions.

- Customization options to fit specific vehicle applications.

- Strict quality control to ensure durability and performance.

Contact us today to discuss your requirements and discover how we can support your business with high-quality engine components.