When you lift the hood of a vehicle, most eyes go straight to the engine block. Yet one of the most important elements of engine performance rests above it—the cylinder head. This vital component may look like a solid block of metal, but inside it are precision-engineered parts and pathways that control how air, fuel, and exhaust move through the engine.

Understanding the cylinder head is crucial for anyone who works with engines, whether it’s a mechanic diagnosing problems, an enthusiast tuning for performance, or a car owner making decisions about maintenance. This article breaks down the cylinder head into its major parts, explains their functions, and explores how they collectively affect engine reliability and efficiency.

What Is a Cylinder Head?

The cylinder head is a cast metal assembly bolted to the top of the engine block. Together with the pistons and cylinders, it creates the combustion chamber where fuel is burned to produce power.

But the head does more than just seal the cylinders. It supports the valvetrain, manages airflow, allows fuel delivery, and contains channels for oil and coolant circulation. In short, the cylinder head is an engine’s control center for combustion and cooling.

Cylinder Head Parts in Detail

1. Casting Body

- Cast Iron: Strong and resistant to wear, common in heavy-duty and diesel applications.

- Aluminum: Lightweight, with better thermal conductivity, favored in modern gasoline engines.

2. Combustion Chamber

The combustion chamber is shaped into the underside of the cylinder head. Its geometry controls compression ratio, flame travel, and efficiency. Small differences in chamber design can influence power output, fuel economy, and emissions.

3. Intake and Exhaust Valves

- Intake Valves: Allow fresh air (and fuel in some designs) to enter.

- Exhaust Valves: Release burned gases after combustion.

4. Valve Seats

Each valve closes against a hardened surface called the valve seat. These rings must create a perfect seal to maintain compression. Worn or damaged seats reduce efficiency and lead to power loss.

5. Valve Guides

Valves slide up and down inside cylindrical guides. These maintain alignment and help transfer heat from the valve stem to the head. Excessive wear in guides can cause oil consumption and smoking exhaust.

6. Valve Springs and Retainers

Every valve has a spring that forces it closed when the camshaft is not pushing it open. Retainers hold the springs in place. If springs weaken, valves may “float” at high RPMs, leading to misfires or engine damage.

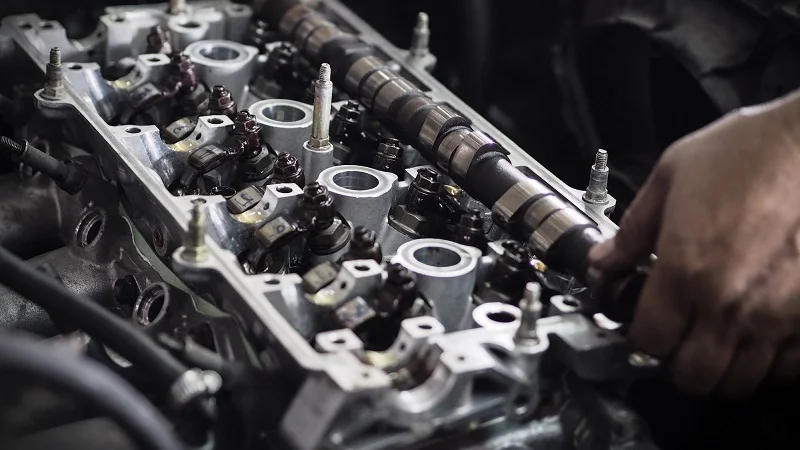

7. Camshaft (OHC and DOHC engines)

- Single Overhead Camshaft (SOHC): One camshaft per cylinder bank, operating both intake and exhaust valves.

- Dual Overhead Camshaft (DOHC): Two camshafts per bank, allowing independent control for intake and exhaust, often used in multi-valve engines.

8. Rocker Arms and Pushrods (OHV designs)

In pushrod (overhead valve) engines, the camshaft is in the block, and motion is transferred through pushrods to rocker arms on the head. Rocker arms then open the valves. Although bulkier, this design is still used in many V8 engines for its torque characteristics and simplicity.

9. Camshaft Bearings and Caps

These keep the camshaft aligned and reduce friction as it spins at high speeds. Without smooth operation here, valve timing would become erratic.

10. Spark Plugs

In gasoline engines, spark plugs thread into the head and ignite the compressed mixture. Their location inside the chamber affects burn efficiency and performance.

11. Fuel Injectors

Modern engines often integrate fuel injectors into the head, especially in direct-injection systems. Accurate injector placement helps achieve complete combustion and reduced emissions.

12. Coolant Passages

Channels inside the head allow coolant to absorb heat and transfer it to the radiator. Poor coolant flow or blocked passages are common causes of overheating.

13. Oil Passages

Lubrication pathways deliver oil to critical moving parts, such as camshaft lobes, lifters, and rocker arms. Adequate oil flow reduces wear and prevents failure under high loads.

14. Exhaust Ports

Exhaust gases travel from the combustion chamber through ports in the head before reaching the manifold. Port design influences back pressure and scavenging, which impact performance.

15. Intake Ports

Fresh air or an air-fuel mixture enters through intake ports. Smooth, optimized ports improve airflow, which translates to more efficient combustion.

16. Head Gasket Surface

The bottom surface of the head mates with the block and is sealed by a head gasket. A flat, precise surface is critical for preventing leaks of gases, oil, or coolant.

17. Cylinder Head Cover

Also known as the rocker cover, this seals the top of the cylinder head, keeping oil inside and contaminants out. In modern designs, it may include PCV (positive crankcase ventilation) systems.

Why Cylinder Head Parts Matter

- Efficient fuel combustion

- Stable engine temperatures

- Consistent lubrication

- Longer service life

Common Cylinder Head Issues

- Warping – Overheating can distort the head, leading to sealing issues.

- Cracks – Aluminum heads are particularly susceptible to cracking under thermal stress.

- Blown Head Gasket – Failure at the gasket surface can cause coolant and oil mixing or loss of compression.

- Valve Damage – Burnt or bent valves reduce compression and cause misfires.

- Carbon Deposits – Excess buildup on valves and ports hinders airflow and combustion.

Maintenance Tips for Cylinder Head Longevity

- Maintain cooling systems: Regular coolant flushes prevent overheating.

- Use quality oil: Ensures proper lubrication of valvetrain components.

- Check valve clearances: Prevents premature wear and ensures smooth operation.

- Inspect gaskets: Look for leaks early to avoid larger failures.

- Avoid overheating: Even one severe overheating incident can warp a head.

Cylinder Head and Performance

For enthusiasts, the cylinder head is one of the most effective areas for performance upgrades. Porting, polishing, larger valves, and advanced camshaft profiles can dramatically increase airflow and horsepower. High-performance heads often feature CNC machining for precision flow improvements.

Even in stock form, the design of a head determines whether an engine emphasizes torque, efficiency, or high-revving power. That’s why manufacturers invest so much effort in head geometry.

Conclusion

The cylinder head is far more than just a cover for the engine block—it is a carefully engineered assembly that manages combustion, airflow, cooling, and lubrication. Each part, from the valves and springs to the oil passages and injector mounts, serves a vital role in ensuring the engine performs reliably.

Recognizing the function of these parts not only helps with diagnosing issues but also highlights the importance of maintenance and quality design. Whether in a compact commuter car or a performance machine, the cylinder head remains at the heart of engine efficiency and durability.