If you take apart almost any modern engine, from a small hatchback to a sports sedan, you’ll find one thing in common — the camshaft sits right on top of the cylinder head. That’s the essence of an Overhead Camshaft Engine (OHC).

It sounds like a simple design change, but this layout is what made modern engines smoother, faster, and more efficient.

Back in the day, engines used what’s called an Overhead Valve (OHV) setup. The camshaft was buried deep in the engine block, and it used long pushrods to reach the valves. It worked fine — especially for low-revving engines — but once revs climbed past 5,000 rpm, the system’s inertia started showing its limits.

That’s when manufacturers began moving the camshaft upward. Placing it directly over the valves removed those pushrods completely. Fewer moving parts meant the valves could open and close faster, timing stayed accurate, and engines could safely spin higher.

That’s basically how the Overhead Camshaft Engine became the new standard.

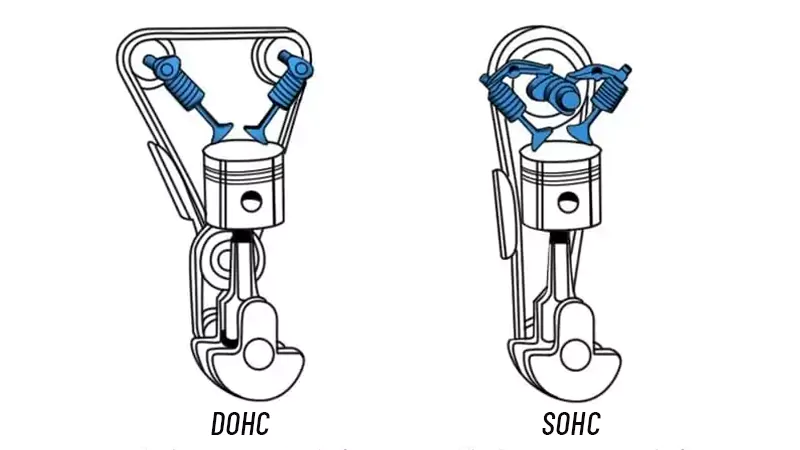

SOHC vs DOHC

A Single Overhead Camshaft (SOHC) engine uses one camshaft per cylinder head. It handles both intake and exhaust valves through short rocker arms. The design is simple and compact — great for reliability and easy maintenance.

A Double Overhead Camshaft (DOHC) engine takes it one step further, adding a separate cam for intake and exhaust. That allows better airflow, more precise valve timing, and support for four-valve-per-cylinder layouts. You’ll find DOHC setups in most modern gasoline and diesel engines because they breathe better and respond quicker at high rpm.

Both systems are still “overhead camshaft” engines — the difference is how much control the engineers want over the combustion process.

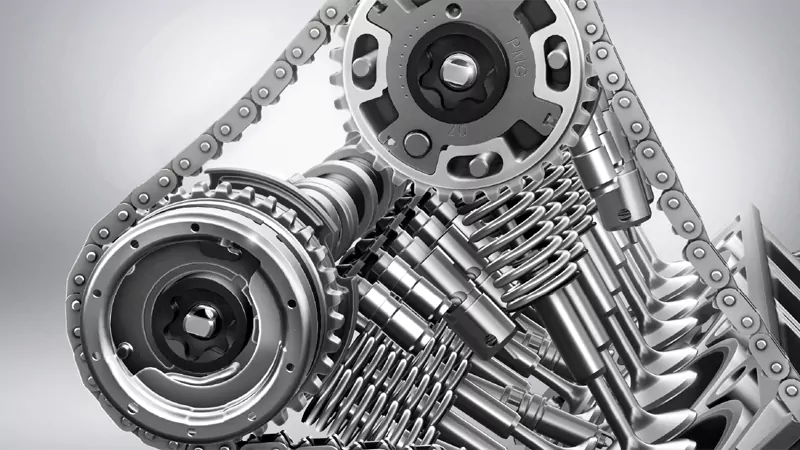

In an OHC engine, the cylinder head is no longer just a cover — it’s the core of the whole valve train. It holds the camshaft bearings, valve guides, seats, and all the oil channels that keep everything alive at high speed. That means the machining accuracy of the head directly affects how smoothly the camshaft rotates and how long it lasts. When tolerances are off, even by a few microns, the camshaft alignment suffers — and that leads to premature wear, oil pressure loss, or noise under load.

That’s why producing high-quality cylinder heads for OHC and DOHC engines isn’t just about casting metal; it’s about maintaining precision and consistency in every surface and bore.

VVT(Variable Valve Timing)

One of the things that really makes modern overhead camshaft engines interesting is Variable Valve Timing, or VVT. Basically, it lets the engine ‘decide’ when to open and close the valves depending on how you’re driving. On older engines with fixed cam timing, the valves open and close at the same moments no matter what — so at low speeds, the engine can feel sluggish, and at high speeds, it can’t breathe efficiently.

With VVT, the camshaft can twist slightly relative to the crankshaft, opening or closing the valves a bit earlier or later. The result? Smooth torque at low RPM, more power at high RPM, and even better fuel efficiency. And because the camshaft in an OHC engine sits right on top of the valves, the system can make these adjustments quickly and precisely. It’s one of those small engineering tweaks that makes a surprisingly big difference in how the engine feels on the road.

Manufacturing and Maintenance Insight

When it comes to overhead camshaft engines, the cylinder head is far more than just a cover. Its design directly dictates valve train behavior, airflow efficiency, and ultimately engine performance. Take a DOHC head as an example: each camshaft sits on precision-machined journals, and even a deviation of a few microns can alter valve timing under high RPM conditions. That might seem minor, but at 7,000–8,000 RPM, a tiny misalignment can reduce volumetric efficiency, increase friction, and accelerate wear on the valve train.

Material selection is another layer of complexity. Aluminum alloys are standard for their light weight and thermal conductivity, but they must withstand cyclic thermal expansion and mechanical stress from cam lobes and valve springs. The casting process itself — whether sand, permanent mold, or high-pressure die casting — affects porosity and structural strength, which in turn impacts long-term reliability.

Oil delivery also plays a subtle but critical role. In an OHC design, oil passages must ensure consistent lubrication for cam journals, rocker arms, and hydraulic lifters. Uneven oil flow can cause local overheating, increased friction, and eventual component failure. Designing these passages requires careful simulation and testing to balance flow rate, pressure, and cooling effect.

Finally, the valve seats and guides determine sealing integrity and precise motion. A head that compromises on guide alignment or seat concentricity can cause valve float, uneven combustion, or premature wear. For manufacturers, maintaining tight tolerances while ensuring repeatable mass production is a constant engineering challenge — and it’s exactly where expertise in precision machining and quality control separates reliable suppliers from average ones.”

At XINJIN, we specialize in producing high-precision cylinder heads for both SOHC and DOHC engines. We focus on maintaining tight tolerances in camshaft journals, valve guides, and oil channels, ensuring every cylinder head delivers the durability, precision, and performance modern engines demand.

For engine rebuilders, importers, and distributors, partnering with a reliable cylinder head manufacturer is critical. If you are looking for custom or bulk production of OHC cylinder heads, we welcome inquiries.