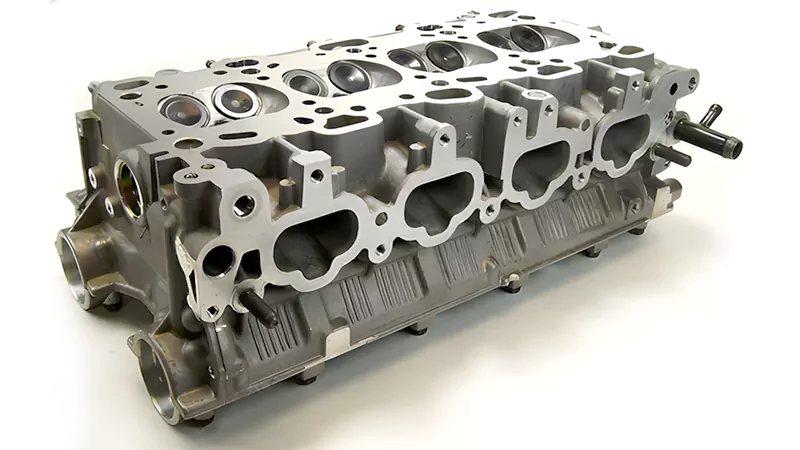

The Mitsubishi 4G63 engine is a legend in the automotive world. From its dominance in the World Rally Championship to its cult status in the Lancer Evolution series and the Eclipse DSM community, this iron-block powerhouse has earned its reputation as one of the most capable four-cylinder engines ever built. However, any seasoned tuner or mechanic will tell you that the secret to unlocking the 4G63’s true potential—or simply keeping it on the road for another 200,000 miles—lies almost entirely in the 4G63 cylinder head.

Whether you are rebuilding a stock daily driver or aiming for a 1,000-horsepower drag strip monster, choosing the right cylinder head is a critical decision. In this guide, we will dive deep into the technical nuances of the 4G63 head, explore common failure points, and analyze what you should look for when sourcing a new replacement from a manufacturing perspective.

Before purchasing a replacement, it is vital to understand that not all 4G63 heads are created equal. The 4G63 enjoyed a long production run, and Mitsubishi made significant architectural changes over the years.

The early generation (1G) heads, found in the 6-bolt engines, are famous for their massive intake ports. Enthusiasts often prefer these for high-RPM power because they allow for incredible airflow. However, the later 2G (7-bolt) heads, while having smaller ports, were designed to increase air velocity, which improves mid-range torque and throttle response.

With the progression of the Lancer Evolution, the cylinder head saw further refinements. The Evo IX, for instance, introduced MIVEC (Mitsubishi Innovative Valve timing Electronic Control system) on the intake side. If you are sourcing a 4G63 cylinder head, you must ensure the casting is compatible with your specific block and oiling system requirements.

When you are in the market for a new casting, you are likely looking for two things: longevity and performance. Because the 4G63 is a high-interference engine, a failure in the cylinder head often leads to catastrophic engine damage. Here is what you must evaluate:

Most aftermarket cylinder heads are cast from aluminum alloys. However, the grade of the aluminum and the heat treatment process (such as T6 tempering) determine how the head handles thermal expansion. A high-quality 4G63 cylinder head should use a refined alloy that resists “dropping” valve seats or developing stress cracks between the valves—a common issue in high-boost applications.

For a factory, the goal is to produce a head that meets or exceeds OEM flow numbers. If the casting is too rough, it creates turbulence. If the ports are inconsistent, cylinders will run at different volumetric efficiencies, making the engine difficult to tune. Look for heads that demonstrate “clean” casting marks or those that have been finished with precision CNC machining.

The relationship between the valve, the guide, and the seat is measured in microns. If the valve guide clearance is too loose, you will burn oil and lose compression. If the valve seat is not perfectly concentric to the guide, the valve will not seal properly, leading to power loss and eventual valve burnt-out. Professional-grade manufacturing ensures that these components are pressed and machined with extreme accuracy.

To choose the right head, you must understand why the old one failed. The 4G63 faces several “occupational hazards” that modern manufacturing has sought to rectify.

The 4G63 generates immense heat, especially in the exhaust manifold area. Over time, this heat cycles the aluminum, leading to hairline cracks, usually between the intake and exhaust valve seats or near the spark plug holes. Modern replacement heads often feature reinforced “thick-wall” sections in these high-stress areas to provide more “meat” for the metal to dissipate heat.

Inadequate oiling or poor surface finishing can lead to the camshaft journals galling. When choosing a new 4G63 cylinder head, inspect the cam journals. They should be mirror-smooth. Manufacturers who utilize high-precision line boring machines can guarantee that the camshafts spin with minimal friction, which is vital for both timing accuracy and engine life.

Older heads often suffer from internal corrosion due to neglected coolant changes. This thins the walls between the combustion chamber and the cooling system. A brand-new casting eliminates this risk entirely, providing a fresh start with full wall thickness and optimal thermal transfer.

For businesses and large-scale distributors, sourcing a 4G63 cylinder head directly from a manufacturing facility offers advantages that a local parts store cannot match.

Factories that specialize in cylinder heads use dedicated tooling and automated CNC centers. This means the 100th head off the line is identical to the 1st. For a B2B client, this consistency reduces the rate of returns and warranty claims.

A factory partner can often provide “blank” or “semi-finished” heads. This allows performance shops to perform their own custom porting or install oversized valves without having to work around pre-installed, lower-grade components.

By eliminating the middleman, you can invest more in the quality of the alloy and the precision of the machining while still maintaining a competitive price point. This is especially important for the 4G63 market, where customers range from budget-conscious repairers to high-end racing teams.

The Mitsubishi 4G63 remains a masterpiece of engineering, but its performance is only as good as its breathing apparatus. Choosing a new 4G63 cylinder head is an investment in the engine’s future. By focusing on casting integrity, machining precision, and correct generational fitment, you ensure that this legendary motor continues to deliver the power and reliability it is known for.

In a market flooded with used, cracked, or poorly refurbished parts, opting for a brand-new, factory-spec cylinder head is the most reliable path for any serious build or professional repair.