The compression ratio is one of the most critical parameters in internal combustion engine design, directly affecting power output, fuel efficiency, combustion stability, and engine longevity. Simply put, it describes how much the air-fuel mixture inside a cylinder is compressed before ignition. This seemingly simple ratio has profound implications on engine behavior. Engineers carefully design the compression ratio to balance performance, fuel consumption, emissions, and mechanical reliability, making it a cornerstone of both gasoline and diesel engine development.

What is the Compression Ratio?

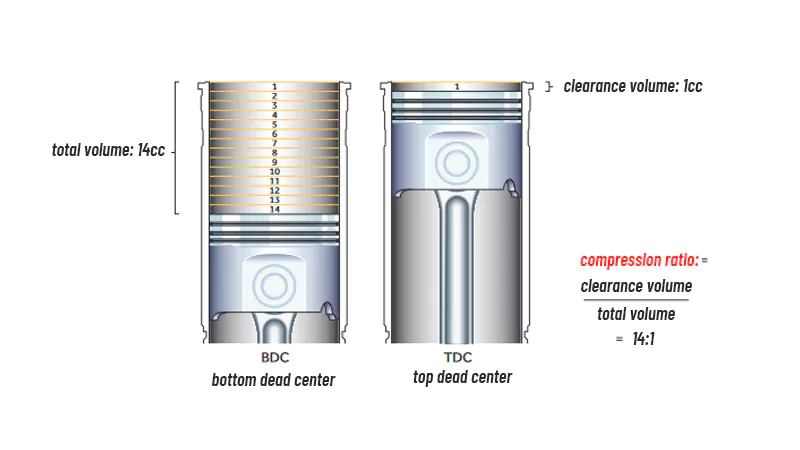

Compression ratio (CR) is defined as the ratio of the cylinder’s total volume when the piston is at bottom dead center (BDC) to the volume when the piston is at top dead center (TDC). The formula is:

CR = (Vd + Vc) / Vc

Where:

- Vd is the displacement volume, the space swept by the piston moving from TDC to BDC.

- Vc is the clearance volume, the remaining space above the piston at TDC.

Displacement volume Vd can be calculated as:

Vd = π/4 × b2 × s

Where b is the cylinder bore and s is the piston stroke. This formula allows engineers to predict the theoretical compression ratio during engine design. Understanding this ratio helps explain why engines with identical displacement can behave differently: the compression ratio determines how tightly the mixture is compressed, which influences the energy available for combustion.

How Compression Ratio Affects Engine Performance?

The compression ratio has a direct and measurable effect on several key aspects of engine performance. A higher compression ratio increases the pressure and temperature of the air-fuel mixture before ignition, which allows the engine to extract more energy from the fuel. This results in higher torque and horsepower outputs. Additionally, higher compression ratios improve thermal efficiency, meaning the engine converts a greater proportion of fuel energy into useful work rather than waste heat.

However, higher compression also increases the risk of engine knocking, where the mixture ignites prematurely due to excessive pressure and temperature. Knocking can damage pistons, cylinder heads, and valves. To mitigate this, engines with high compression ratios often require high-octane fuel that resists premature ignition. Conversely, lower compression ratios reduce the risk of knocking but generally sacrifice efficiency and power. Turbocharged engines often adopt lower compression ratios to prevent detonation under boost, while naturally aspirated engines can safely use higher ratios for maximum efficiency.

Components That Influence Compression Ratio

The actual compression ratio of an engine depends on several engine components:

- Cylinder Head Design: The volume and shape of the combustion chamber determine the clearance volume at TDC. Compact, hemispherical chambers reduce Vc and increase CR, while larger chambers lower it.

- Piston Top Shape: Domed pistons increase compression by reducing clearance volume, whereas dished pistons lower compression. Flat-top pistons provide a balance.

- Head Gasket Thickness: Thicker gaskets slightly increase the clearance volume, reducing CR; thinner gaskets do the opposite.

- Piston Deck Height: The distance between the piston at TDC and the cylinder block surface also influences Vc and therefore the final compression ratio.

Even minor changes in these components can noticeably alter engine performance, which is why precision machining and assembly are crucial in engine manufacturing and modification.

Typical Compression Ratios

Compression ratios vary significantly depending on fuel type, engine design, and application:

- Naturally aspirated gasoline engines: 9:1 to 11:1

- Turbocharged gasoline engines: 8:1 to 10:1, to prevent detonation under boost

- Diesel engines: 14:1 to 22:1, since diesel relies entirely on compression heat for ignition

- High-performance gasoline engines: up to 13:1 or slightly higher when using high-octane fuels

These ranges illustrate how engineers balance efficiency, power, and reliability according to engine purpose.

While compression ratio can be calculated theoretically from cylinder geometry, actual compression ratio may vary due to manufacturing tolerances, carbon buildup, or assembly differences. Mechanics measure it using specialized tools: cylinders are often filled with a liquid, and the displaced volume is measured to determine the real CR. During engine rebuilding or tuning, compression ratio can be adjusted by:

- Modifying the combustion chamber shape on the cylinder head

- Installing pistons with different dome heights

- Changing gasket thickness

- Adjusting piston deck height

Such modifications require careful engineering, as improper adjustments can lead to knocking, reduced efficiency, or mechanical damage.

Conclusion

In conclusion, the compression ratio is a defining characteristic of an internal combustion engine. It is determined by the ratio of cylinder volumes at BDC and TDC and is influenced by piston design, cylinder head shape, gasket thickness, and other factors. A well-designed compression ratio balances power, fuel efficiency, reliability, and fuel requirements. Precision in both calculation and manufacturing is essential, making the compression ratio not only a number but a critical aspect of engine performance and design.