When we talk about car engines, we often focus on pistons, crankshafts, or turbochargers. But there’s one crucial component that rarely gets enough attention — the cylinder head. This single part is responsible for sealing the top of the engine, housing critical components, and ensuring that combustion — the very process that powers your car — happens efficiently and safely.

In this article, we’ll take a deep dive into what the cylinder head is, what it does, its parts, materials, and why it’s so important to your vehicle’s performance. Whether you’re a car enthusiast, mechanic, or business owner in the auto parts industry, this guide will give you a complete understanding of the cylinder head — explained in simple, everyday language.

What Is a Cylinder Head?

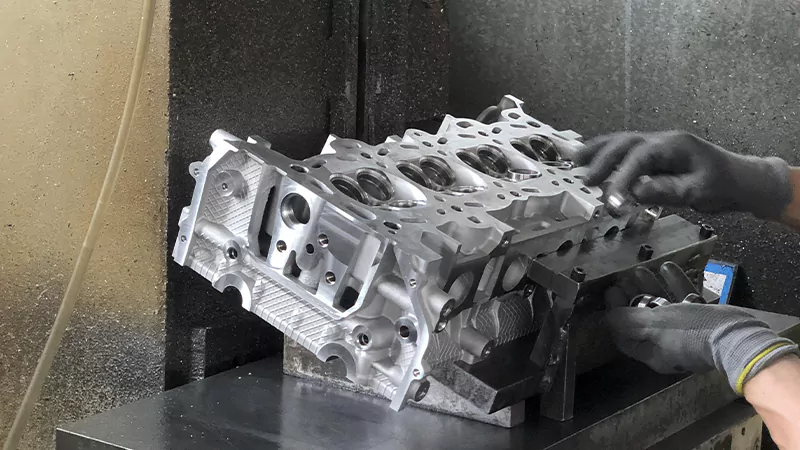

The cylinder head is a major component of an internal combustion engine (often called “IC engine”).

It’s located at the top of the engine block, forming the upper seal of the combustion chamber — the place where air and fuel mix and explode to generate power.

In simple terms, imagine your engine as a box of metal cylinders where pistons move up and down. The cylinder head acts as the lid of that box.

It keeps everything inside — fuel, air, and heat — under control.

A typical cylinder head is made from metal castings (usually aluminum or cast iron) and contains numerous channels and openings. These allow coolant, oil, air, and exhaust gases to pass through in a carefully controlled way.

The Basic Function of a Cylinder Head

The cylinder head performs several critical functions that directly affect how well your engine runs. Let’s break them down in simple terms:

1. Sealing the Combustion Chamber

The cylinder head’s main job is to close off the top of each cylinder, creating a sealed chamber with the help of a cylinder head gasket. This seal must withstand intense pressure and high temperatures — sometimes exceeding 1,000°C — every time the fuel-air mixture ignites.

Without a tight seal, the engine would lose compression, leading to power loss, oil leakage, or even engine damage.

2. Housing Critical Engine Components

The cylinder head holds many important parts that control how the engine “breathes” and burns fuel efficiently.

These include:

- Intake and exhaust valves

- Valve guides and valve seats

- Camshaft(s) (in overhead camshaft engines)

- Spark plugs or fuel injectors

Each of these components has a specific role. Valves open and close to allow air in and push exhaust gases out. Spark plugs ignite the fuel-air mixture. The camshaft controls the timing of these actions, ensuring your engine runs smoothly.

3. Directing Oil, Coolant, and Gases

Inside the cylinder head are many passageways, also called ports or galleries, that guide fluids and gases:

- Coolant circulates through the head to absorb heat and prevent overheating.

- Oil lubricates moving parts such as valves and camshafts.

- Air and exhaust gases flow in and out of the cylinders through intake and exhaust ports.

Without these internal channels, the engine would quickly overheat and seize up.

4. Withstanding Heat and Pressure

Because combustion happens right beneath it, the cylinder head must tolerate extreme temperatures and pressures.

To handle this stress, it’s made from durable materials like aluminum alloys or cast iron, and mounted securely with high-tensile bolts or studs. The shape of the head — especially the area known as the combustion chamber — is carefully engineered to control the flow of gases and maximize efficiency.

Cylinder Head Structure and Components

A cylinder head may look like a single metal block, but it’s actually a complex assembly containing multiple precision-engineered parts. Let’s explore these components one by one:

Combustion Chamber

This is the hollowed-out space on the underside of the cylinder head.

When the head is bolted to the block, this cavity combines with the top of the piston and the cylinder walls to form the combustion chamber.

The size and shape of this chamber influence:

- Compression ratio

- Fuel efficiency

- Power output

- Emissions

High-performance engines often use specially designed combustion chambers for better air-fuel mixing and faster flame travel.

Valves (Intake and Exhaust)

Valves control the “breathing” of the engine.

- Intake valves let the air-fuel mixture enter the cylinder.

- Exhaust valves allow burnt gases to exit after combustion.

They open and close in precise timing with the piston’s movement. Poorly sealing valves can cause compression loss, misfires, or reduced performance.

Valve Guides and Seats

Each valve slides up and down inside a valve guide, which keeps it aligned.

At the bottom, the valve closes against a valve seat to form an airtight seal.

These parts must be perfectly machined to maintain compression and prevent gas leakage.

Spark Plug Mounts / Injector Ports

In gasoline engines, the cylinder head includes threaded holes for spark plugs, which ignite the air-fuel mixture. In diesel engines, instead of spark plugs, you’ll find fuel injector ports, where injectors spray fuel into the combustion chamber.

Camshaft and Valvetrain

In OHC (Overhead Camshaft) or DOHC (Double Overhead Camshaft) engines, the camshaft is located in the cylinder head.

Its job is to open and close the valves using lobes that push on rocker arms or valve lifters.

The camshaft is synchronized with the crankshaft via a timing belt or timing chain.

Coolant and Oil Passages

The head contains internal channels that allow coolant and oil to circulate.

- Coolant removes heat from the combustion area.

- Oil lubricates the moving parts, reducing friction and wear.

Proper circulation keeps the engine temperature stable and ensures longevity.

Cylinder Head Gasket

Although technically a separate part, the cylinder head gasket is one of the most critical components.

It seals the joint between the cylinder head and the engine block, preventing the leakage of combustion gases, coolant, or oil.

A damaged gasket — known as a blown head gasket — can cause overheating, white smoke, or severe engine damage.

Cylinder Head Materials

Cylinder heads are mainly made from two materials:

Aluminum Alloy

Lightweight, excellent at conducting heat, and ideal for modern gasoline engines. Aluminum helps engines warm up and cool down quickly, improving fuel economy. However, it’s softer and more prone to warping if overheated.

Cast Iron

Stronger and more durable than aluminum, cast iron is often used in diesel and heavy-duty engines. It can handle higher compression ratios and extreme temperatures but is heavier and dissipates heat more slowly.

Some manufacturers use hybrid designs — for example, a cast iron block with an aluminum head — to balance strength and weight.

Reliable Cylinder Head Manufacturer

At XINJIN, we specialize in producing high-quality cylinder heads, cylinder blocks, and other precision engine components. With years of manufacturing experience and advanced casting and machining capabilities, we provide reliable solutions for both OEM and aftermarket applications.

Whether you need cylinder heads for Toyota, Isuzu, Nissan, Hyundai, or other vehicle brands, XINJIN delivers parts you can trust. Looking for a dependable cylinder head supplier?

Contact XINJIN today to discuss your requirements.

We offer OEM manufacturing, custom solutions, and bulk supply for global markets.