What is a Crankshaft and How It Works?

The crankshaft is the beating heart of any internal combustion engine. Its main role is to convert the reciprocating motion of the pistons into rotary motion, which ultimately drives the wheels of a car or motorcycle. Despite being a single piece of metal, a crankshaft experiences some of the most extreme forces in an engine and directly affects engine smoothness, performance, and longevity. Understanding its structure, function, and critical components is essential for maximizing engine efficiency and durability.

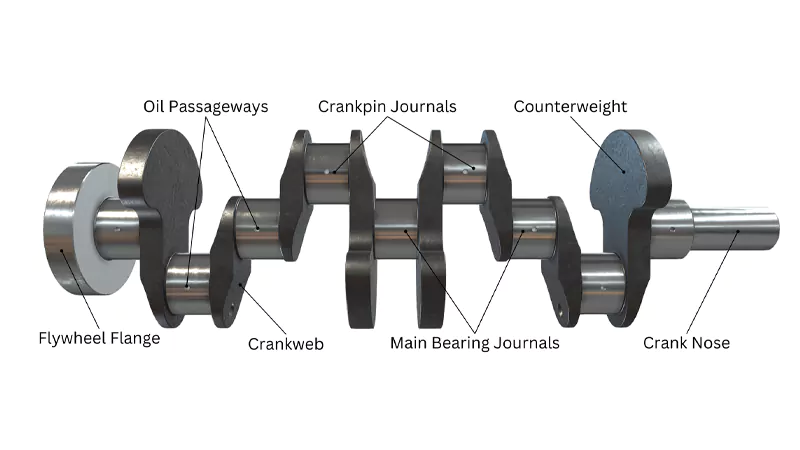

Crankshaft Components

Main Journals

The main journals are the central surfaces on which the crankshaft rotates. They rest in the main bearings, which are secured in the engine block by main caps. These journals carry the majority of the engine’s load and are responsible for keeping the crankshaft aligned during high-speed rotation. Their diameter, surface finish, and lubrication design are critical for durability, as any misalignment or insufficient lubrication can lead to bearing wear or catastrophic failure. Main journals are typically precision-ground and polished to ensure smooth rotation, minimize friction, and withstand extreme forces generated by combustion and piston movement.

Rod Journals(Crankpin Journals)

Rod journals, also known as crank pins or big end journals, are the surfaces where the connecting rods attach to the crankshaft. Each rod journal connects the “big end” of a connecting rod, transmitting the linear motion of the piston into rotational motion. The rod journals are offset from the main journals, creating the crank throw, which defines the engine stroke. The offset distance directly affects piston travel and, therefore, engine displacement. Rod journals also feature oiling passages to ensure proper lubrication under high RPM and extreme loads, preventing metal-to-metal contact and reducing wear on the bearing surfaces.

Crank Webs

Crank webs, sometimes called crank arms, are the structural elements connecting main journals to rod journals. They provide rigidity and strength, resisting twisting forces caused by piston acceleration and combustion pressure. The shape and thickness of the crank webs are carefully engineered to balance strength and weight. Thicker webs provide more durability for high-performance applications, while thinner webs reduce overall crankshaft weight for high-revving engines. Additionally, the web geometry can influence the crankshaft’s ability to be balanced dynamically, affecting engine smoothness and vibration characteristics.

Crank Throw or Crank Radius

The crank throw, also referred to as the crank radius, is the distance from the centerline of the main journal to the centerline of the rod journal. This measurement determines the piston’s vertical travel, which is known as the engine stroke. The stroke length, in combination with the bore diameter, defines the engine’s displacement. Longer crank throws result in higher torque at lower RPMs, while shorter throws allow higher engine speeds with less piston acceleration stress. Proper crank throw design is critical for achieving the desired balance between torque, engine speed, and mechanical reliability.

Oiling Passages in Journals

Both main and rod journals contain oiling passages, small drilled holes that deliver pressurized engine oil to the bearing surfaces. These passages are often cross-drilled or designed as straight-shot oiling systems, ensuring that a thin film of oil separates the journals from the bearings. Proper oiling reduces friction, prevents overheating, and dramatically increases the lifespan of the crankshaft and its associated components. Chamfered oil holes are standard in quality crankshafts to avoid turbulence and cavitation in the oil flow.

Fillets and Stress Relief

At the junctions between journals and webs, radius fillets are machined to reduce stress concentrations. Sharp corners would create weak points prone to cracking under cyclic loads. By using a proper radius fillet, engineers spread the load more evenly across the crankshaft material, enhancing fatigue resistance and improving durability. In high-performance or racing applications, these fillets are optimized to withstand higher RPMs and combustion pressures.

The Flywheel, Nose, and Counterweights

At one end of the crankshaft is the flywheel flange, which attaches the flywheel. The flywheel smooths out pulsating forces from combustion, reducing vibrations and improving engine balance. The opposite end is the nose, where the crank pulley is mounted to drive essential engine accessories. Counterweights balance the forces from pistons, rings, and connecting rods, reducing vibration and ensuring smooth operation. Properly designed radius fillets at stress points prevent cracks and fatigue failure, critical for crankshaft longevity.

The crankshaft is subjected to immense forces. Combustion pressures in naturally aspirated gasoline engines can reach 100 bar, while diesels or forced induction engines may see up to 200 bar. A single piston under 100 bar generates roughly 18,000 pounds of force, repeated thousands of times per minute. Multi-cylinder engines increase these forces, creating complex vibrations and torsional twisting. Despite this, a well-designed crankshaft can withstand these stresses for hundreds of thousands of hours.

Crankshaft Manufacturing Methods

Crankshaft manufacturing greatly affects strength and performance. Casting is cost-effective but produces brittle parts due to random grain structures. Forging compresses and aligns grain structure, improving strength and ductility, with steel alloys like 4140, 5140, and 4340 commonly used for performance applications. Billet crankshafts are CNC-machined from solid metal billets, retaining optimal grain structure and allowing custom designs. Billet machining provides precision, accurate journal placement, and superior balance.

Surface hardening increases wear resistance and durability. Induction hardening quickly hardens journal surfaces for mass production, but can leave uneven stress. Tufftriding creates a uniform, wear-resistant layer, while nitriding hardens surfaces evenly without warping. High-performance engines often use these treatments to withstand extreme forces. After regrinding, surface treatment must be reapplied to restore hardness and wear resistance.

Flat-Plane vs Cross-Plane Crankshafts

Crankshafts are categorized into flat-plane and cross-plane designs. Flat-plane crankshafts have journals in a single plane, allowing higher RPM, lower weight, and compact size, ideal for inline-four engines and high-revving applications. They produce more vibration but enable faster engine response. Cross-plane crankshafts have journals offset 90 degrees, offering smoother operation, better low-end torque, and the signature V8 sound. However, they are bulkier and heavier, limiting high RPM capability. Choosing the correct design depends on performance goals and engine configuration.

Conclusion

The crankshaft isn’t just another engine part—it’s the heart that keeps your engine alive and kicking. Every rotation, every combustion stroke, every piston movement pushes it to its limits. A poorly designed or weak crankshaft can turn even the most powerful engine into a headache, while a well-engineered crankshaft makes the car feel smooth, responsive, and reliable, even under extreme conditions.

At XINJIN, we don’t just make crankshafts—we engineer peace of mind for your engine. Whether it’s a high-performance build, a daily driver, or a custom project, our precision-machined crankshafts, forged or billet, are designed to last, perform, and keep every piston firing exactly where it should. Choosing the right crankshaft isn’t just about metal and machining—it’s about making sure your engine performs at its absolute best, mile after mile.