The term engine head typically refers to the cylinder head in an internal combustion engine. The cylinder head is a critical component that sits atop the engine block, sealing the cylinders while housing numerous key components. It controls air and fuel intake, exhaust flow, combustion, and plays a central role in engine performance and durability. Let’s explore the engine head in full detail.

How Does The Engine Head Work?

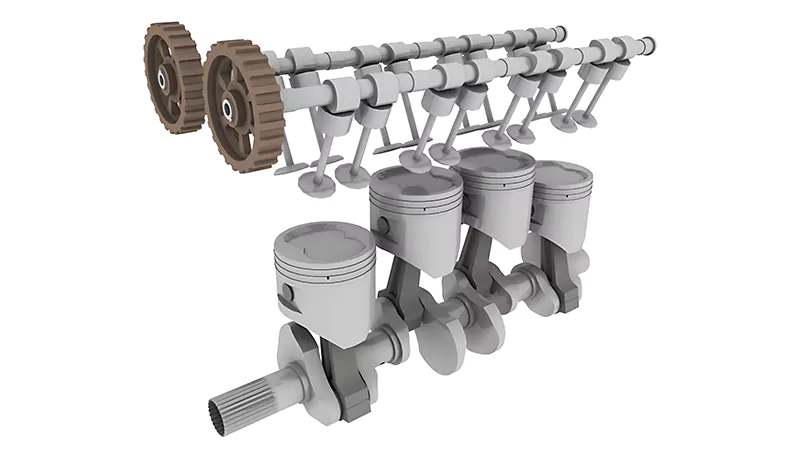

The cylinder head sits on top of the engine block and contains the valves, which regulate the flow of air and fuel into the cylinders and the expulsion of exhaust gases. The camshaft, driven by the crankshaft, opens and closes the valves at precise intervals.

Inside the head, the combustion chambers are where the air-fuel mixture ignites. This controlled explosion generates power that drives the vehicle. The cylinder head also contains passages for coolant and oil, which maintain operating temperature and lubricate moving parts such as the camshaft, valve train, and lifters.

In essence, the cylinder head ensures proper air-fuel delivery, efficient combustion, and safe heat dissipation, making it integral to engine function.

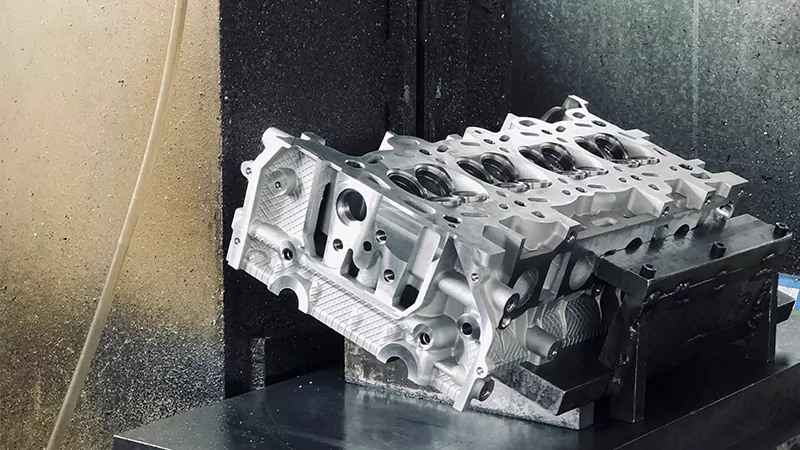

What Material Is Used To Make An Engine Head?

Cylinder heads must withstand high temperature, pressure, and mechanical stress while providing good thermal conductivity. Common materials include:

- Aluminum Alloy: Lightweight, excellent heat dissipation, widely used in modern engines. Often used with precision casting and CNC machining to maintain dimensional stability.

- Cast Iron: Heavier, very durable, and resistant to wear. Often used in heavy-duty or industrial engines.

The choice of material affects heat management, engine weight, and long-term durability.

Areas in an Engine Head

Combustion Chambers

The cylinder head houses the combustion chambers where the air-fuel mixture ignites. Chamber shape (hemispherical, pentroof, wedge) affects airflow, combustion efficiency, and engine power. Proper design minimizes heat loss and prevents knock.

Valve Seats

Valve seats are precision-machined surfaces where valves close tightly. They prevent combustion gas leakage, maintain compression, and are typically hardened to resist wear.

Intake and Exhaust Ports

These passages guide air-fuel mixture into cylinders and exhaust gases out. Their geometry, smoothness, and cross-sectional area significantly influence engine volumetric efficiency and performance.

Coolant Passages

Cylinder heads include passages for coolant circulation. Proper flow prevents hotspots, maintains optimal combustion temperature, and protects against warping.

Oil Passages

Oil passages deliver lubrication to camshaft journals, lifters, valve stems, and rocker arms. Proper lubrication prevents premature wear and ensures smooth operation at high RPM.

Valve Technologies

Valves

Engine heads contain intake and exhaust valves. These control airflow and gas expulsion. Valves must withstand high temperatures and repeated impacts. Typical materials are hardened steel alloys for durability.

Valve Springs

Valve springs return valves to the closed position. Their stiffness must be calibrated to engine RPM and camshaft profile. Incorrect spring tension can cause valve float or poor sealing.

Valve Guides

Cylindrical sleeves that guide valve movement, ensuring alignment and smooth motion. Often made from cast iron or bronze.

Camshaft

Controls valve timing via lobes pushing lifters. Camshaft profile determines valve lift, duration, and overlap, directly affecting torque and power curves.

Timing Chain & Timing Belt

- Timing Chain: Metal, durable, placed inside the engine, lasts long but noisy. Replacement is labor-intensive.

- Timing Belt: Rubber reinforced with fibers, quieter, external, requires periodic replacement. Less expensive but shorter lifespan.

Spark Plugs

In gasoline engines, spark plugs ignite the air-fuel mixture. Placement and heat rating are critical for combustion efficiency.

Fuel Injectors

Deliver fuel to intake ports or directly into the combustion chamber.

- Port Fuel Injection (PFI): Sprays fuel into intake ports.

- Direct Injection (DI): Sprays fuel directly into combustion chamber.

Head Gaskets

Seals cylinder head to engine block, preventing oil, coolant, and combustion gas leaks. Gasket failure can lead to overheating and compression loss.

Bolts and Fasteners

Secure the cylinder head and maintain proper sealing. Correct torque sequence is critical to prevent warping.

Components in an Engine Head

Modern engines often use multiple valves per cylinder to optimize performance:

- Two Valves: 1 intake, 1 exhaust – typical in small engines.

- Three Valves: 2 intake, 1 exhaust – balances airflow and cost.

- Four Valves: 2 intake, 2 exhaust – improves combustion efficiency and power output.

Variable Valve Timing (VVT) allows the timing of intake/exhaust valves to adjust dynamically. This enhances fuel efficiency, reduces emissions, and improves performance across RPM ranges.

Types of Engine Heads

Cylinder head designs differ based on valve placement, camshaft configuration, and airflow management. The main types are:

Overhead Valve (OHV)

- Valves are located in the engine block and actuated via pushrods and rocker arms.

- Simple and reliable design, with fewer components in the cylinder head.

- Limited high-RPM performance due to inertia of pushrods, which can restrict valve speed and timing accuracy.

Single Overhead Camshaft (SOHC)

- A single camshaft in the cylinder head controls both intake and exhaust valves.

- Offers better valve timing precision than OHV.

- Fewer moving parts than DOHC, balancing complexity and performance.

Dual Overhead Camshaft (DOHC)

- Two camshafts in the cylinder head separately control intake and exhaust valves.

- Allows higher engine RPM and precise valve timing.

- Supports advanced technologies like variable valve timing (VVT) for optimized efficiency and performance.

Crossflow

- Intake and exhaust ports are positioned on opposite sides of the cylinder head.

- Promotes efficient airflow through the combustion chamber.

- Enhances volumetric efficiency and overall engine performance, especially in naturally aspirated and high-performance engines.

Conclusion

The cylinder head is central to engine performance, efficiency, and longevity. Understanding its materials, components, valve technologies, and configurations is essential for mechanics, engineers, and enthusiasts. From proper airflow management to precise valve timing, every detail in the engine head affects how your engine performs.

Looking for reliable, precision-engineered cylinder heads for your business? Get in touch to explore custom solutions, volume pricing, and technical support.