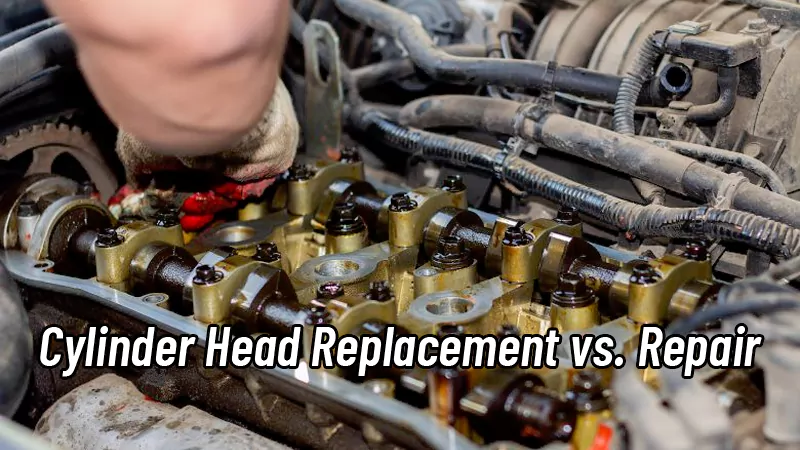

Think of your car’s engine as a grand symphony. Each component has its own role, from the pistons moving rhythmically to the crankshaft turning in precise timing. Yet the conductor of this orchestra is the cylinder head, the part that governs the combustion process and keeps the whole performance in harmony. When this conductor falters, the consequences can be serious. A cracked or damaged cylinder head disrupts performance, leads to overheating, and in the worst cases, brings the engine to a halt. At that point, every vehicle owner or fleet manager is faced with the crucial choice: should the cylinder head be repaired, or is replacement the only reliable solution?

What Causes Cylinder Head Failure?

The cylinder head endures some of the harshest conditions in the engine. Positioned above the block, it withstands enormous pressure and temperature fluctuations. Over time, this exposure inevitably leads to wear and sometimes failure. Cracking is perhaps the most common issue. When an engine overheats, metal expands beyond its safe limits and fractures appear. Poor cooling system maintenance, a failing water pump, or a clogged radiator often lies at the heart of this problem. Even rapid changes in temperature—like pouring cold coolant into a hot engine—can shock the metal and cause cracks to form.

Mechanical failure represents another common pathway to damage. A broken valve spring, for example, can let the valve drop and strike the piston, while a faulty camshaft or improper installation of components can place abnormal stress on the head. When bolts are over-tightened or unevenly torqued, the structure can distort, setting the stage for bigger problems later.

The combustion chambers inside the head are particularly sensitive. With repeated exposure to extreme pressure and heat, they can warp or sink. This deformation disrupts compression, reducing efficiency and sometimes allowing oil or coolant to leak. In engines where low-quality coolant is used, corrosion and erosion can make things even worse, eating away at delicate passages and gradually undermining structural strength.

Recognizing the Symptoms

Cylinder head problems rarely appear suddenly. Instead, there are usually warning signs that, if spotted early, can save both money and downtime. White smoke flowing from the exhaust often indicates that coolant has entered the combustion chamber. Persistent overheating, even when coolant levels appear correct, points to a deeper problem inside the head or its gasket. Many drivers also notice a significant loss of power, engine misfires, or the unsettling appearance of a milky substance on the oil dipstick, which means coolant and oil are mixing. In some cases, coolant leaks may even be visible externally along the head’s surface. Ignoring these symptoms usually allows minor defects to escalate into catastrophic damage.

Can Cylinder Heads Be Repaired?

The natural question most vehicle owners ask is whether a damaged cylinder head can be saved. In many cases, the answer is yes, but the extent of the damage matters greatly. Small cracks can often be repaired through welding or a process called metal stitching, where specialized inserts restore strength to the weakened area. When a head has warped, machining and resurfacing can restore the flatness needed for a proper seal. If valves, seals, or guides are damaged, these can typically be replaced without scrapping the entire unit.

Repairs make sense when damage is limited to minor cracks or slight warping, and when the head has not already been heavily worked on in the past. However, when cracks stretch across combustion chambers or coolant passages, or when the head has been overheated multiple times, repairs become unreliable. In such cases, the structural integrity is already compromised, and no amount of welding or machining can guarantee long-term performance.

Repair Vs. Replacement

The choice between repairing and replacing a cylinder head is never trivial. Repair tends to be the cheaper solution in the short term. It preserves the original OEM part, which often fits better than aftermarket alternatives, and it can be completed more quickly when the issues are minor. However, repaired heads may not fully regain their original strength. They are more prone to future problems, especially in high-stress operating environments.

Replacement, on the other hand, offers peace of mind. A brand-new or remanufactured head restores the engine to like-new condition and provides greater reliability over the long haul. While the upfront cost is higher, it often proves more economical for fleet operators or those who rely heavily on their vehicles, since it reduces downtime and avoids repeat failures. For an individual car owner with an older vehicle, repair might be a practical choice. But for businesses managing multiple units or vehicles covering high mileage, replacement usually represents the smarter investment.

Preventing Cylinder Head Problems

While the debate between repair and replacement is important, prevention remains the best strategy. Proper cooling system maintenance is vital, since overheating is the leading cause of damage. Using the manufacturer-recommended coolant and changing it at regular intervals helps prevent corrosion and erosion. Drivers should never ignore the engine temperature gauge; overheating warnings should be taken seriously, and engines should be shut down immediately to avoid cracks and warping. Regular inspections by qualified technicians can catch small leaks, worn gaskets, or early signs of distortion before they become costly issues. Even the installation process matters—head bolts must always be torqued to specification, as improper tightening is a surprisingly common cause of long-term failure.

Conclusion

The cylinder head serves as both the brain and the heart of the engine. Without it, the combustion process cannot function, and the entire symphony of mechanical motion falls apart. Damage to this critical part often begins with overheating, poor maintenance, or mechanical stress, and if left unaddressed, it leads to serious consequences. Recognizing the early warning signs—smoke, overheating, oil contamination, or loss of power—can prevent total failure and guide owners toward timely repair or replacement.

Repair can restore functionality when the damage is minor, but replacement is often the only reliable solution when cracks, warping, or corrosion have gone too far. For individuals, the choice may depend on budget and vehicle age, but for businesses and fleet operators, replacement is usually the more cost-effective path in the long run.

Ultimately, a well-maintained cylinder head ensures that your engine orchestra continues to play in perfect harmony, delivering performance, efficiency, and reliability for years to come.

If you are a distributor, workshop, or parts wholesaler looking for a trusted supplier, we are a professional cylinder head manufacturing factory. At XINJIN, We provide high-quality products, support customization, and offer bulk supply to meet your business needs. Get in touch with us today to discuss cooperation and secure reliable cylinder head solutions for your market.