When it comes to building a high-performance engine, the foundation of your build starts with the engine block. This critical component houses the cylinders, pistons, crankshaft, and other essential engine parts, meaning its quality directly affects durability, performance, and reliability. Over the years, engine blocks have primarily been produced using two methods: casting and billet CNC machining. Understanding the differences between cast engine blocks and billet engine blocks is vital for anyone looking to upgrade their vehicle, build a race engine, or simply optimize performance.

In this article, we will dive deep into the advantages and disadvantages of each type of engine block, explore their applications, and help you determine which is best suited for your project. Whether you are a street car enthusiast or a professional drag racer, this guide will provide the insights you need to make an informed decision.

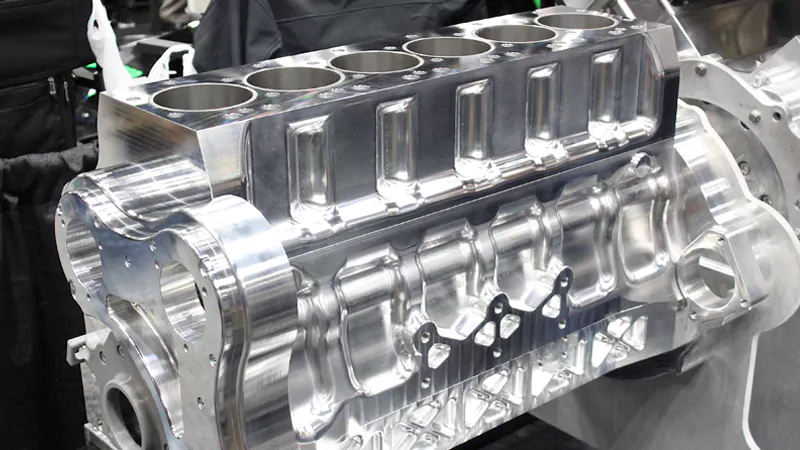

What is a Billet Engine Block?

A billet engine block takes a completely different approach. Instead of casting, the block is made from a solid piece of high-grade aluminium or steel, which is then CNC-machined into the exact shape of the engine block. This method is significantly more labor-intensive and expensive but offers numerous performance advantages.

Advantages of Billet Engine Blocks

- Superior Strength and Durability

Because a billet block is machined from a solid piece of metal, it eliminates any porosity or weak spots associated with casting. This results in a denser, more uniform structure that can withstand extreme horsepower, torque, and high RPMs. - Precision Machining

CNC machining ensures tighter tolerances and precise dimensions, which is critical for high-performance engines where every micron counts. This precision improves reliability and reduces the likelihood of warping or deformation. - Customizable Design

Billet blocks can be fully customized, allowing engine builders to design larger bore sizes, additional oil channels, reinforced cylinder walls, and improved coolant flow tailored for specific racing or performance applications. - High-Performance Applications

Billet engine blocks are the preferred choice for drag racing, drifting, endurance racing, and extreme forced-induction builds. They are often paired with aftermarket crankshafts, high-lift camshafts, and oversized pistons to maximize output.

Disadvantages of Billet Engine Blocks

- High Cost

Billet blocks are significantly more expensive than cast blocks. Prices can range from a few thousand to tens of thousands of dollars, depending on the material, machining, and complexity of the build. - Availability

Unlike cast blocks, billet blocks are usually produced in limited quantities. This means lead times can be longer, and finding a ready-made billet block for a specific engine may be more challenging. - Weight Considerations

Depending on the material and design, billet blocks can sometimes be heavier than cast aluminium blocks. However, this is often offset by the added strength and durability.

What is a Cast Engine Block?

Traditional cast engine blocks have been the standard in the automotive industry for decades. In simple terms, a cast engine block is made by pouring molten iron or aluminium into a mold, allowing it to cool and solidify into the shape of the engine block. Once cast, the block undergoes machining to create precise surfaces for the cylinders, crankshaft, and other components.

Advantages of Cast Engine Blocks

- Cost-Effective Manufacturing

Casting allows manufacturers to produce engine blocks in large quantities at a relatively low cost. This is why almost every mass-produced car on the market uses a cast engine block. - Availability

Cast engine blocks are widely available for almost every type of engine, from economy cars to trucks. Replacement parts are easier to find, and aftermarket support is abundant. - Sufficient for Standard Applications

For daily drivers, family cars, or even moderately tuned vehicles, a cast engine block provides more than enough strength and reliability.

Disadvantages of Cast Engine Blocks

- Potential Weak Spots

The casting process can sometimes create porosity, air pockets, or other minor defects in the material. While this usually doesn’t affect performance in stock applications, it can limit durability under extreme loads, such as in drag racing or high-boost forced induction setups. - Limited Customization

Cast engine blocks are made to specific molds, meaning modifications or custom designs are limited compared to billet blocks.

Key Considerations Before Choosing

When deciding between a billet block and a cast block, consider the following:

- Your Engine Goals

Are you building a street car, or a high-horsepower race engine? For extreme performance, billet is superior. - Budget Constraints

Billet blocks are costly. Cast blocks are practical if you have budget limitations. - Availability and Lead Time

Cast blocks are widely available, while billet blocks may require ordering and waiting for CNC machining. - Durability Requirements

Consider the stresses your engine will face. High-boost turbo engines, high-RPM builds, and racing engines benefit from the superior strength of billet blocks. - Customization Needs

Billet blocks allow modifications to bore size, wall thickness, and coolant passage design. Cast blocks are limited to their original mold design.

Conclusion

Choosing between a billet engine block and a cast engine block ultimately depends on your build goals, budget, and performance requirements. If your goal is to maximize engine performance and durability, investing in a billet block may be worth the cost. However, for everyday reliability and affordability, a cast block will serve you well.

At XINJIN, we specialize in manufacturing OEM engine blocks, cylinder heads, and complete engine components. With decades of experience and precision CNC machining, we deliver high-quality, durable, and reliable products for both standard applications and high-performance builds. Upgrade your engine today with our OEM-engineered blocks and cylinder heads. Contact us now to get a quote and expert guidance for your next project.