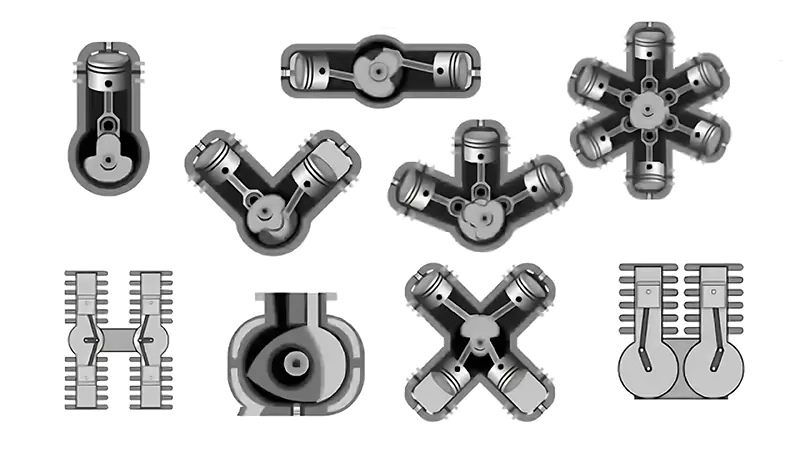

The engine is the heart of any vehicle, and the cylinder serves as its core power unit. Fuel is burned inside the cylinder and converted into mechanical energy, which powers the vehicle. The number of cylinders directly influences an engine’s potential power output: more cylinders typically mean higher power and smoother operation. Modern engines often come in configurations with four, six, or eight cylinders, but there are also unique layouts with one, twelve, or even sixteen cylinders, each designed for specific performance and packaging requirements. While the basic principles of internal combustion engines are universal, design, functionality, and application vary greatly. This article explores the main engine layouts used in the automotive industry, from the simplest single-cylinder engines to complex multi-bank configurations and specialized designs.

Single-Cylinder Engines

Single-cylinder engines are piston engines containing only one cylinder. They are commonly used in motorcycles, scooters, go-karts, all-terrain vehicles, and small industrial machinery. These engines are produced in both two-stroke and four-stroke versions.

The first gasoline engine developed by Carl Benz in 1879 was a single-cylinder, two-stroke design, marking the beginning of modern automotive propulsion.

Advantages

Single-cylinder engines are less expensive to manufacture due to their simple construction. Their design allows greater airflow around the cylinder, making air-cooling more effective compared to multi-cylinder engines. Because of their larger bore and stroke relative to engine size, they generate high torque at low revolutions per minute (RPM), making them ideal for load-carrying applications or vehicles that require strong low-end torque.

Limitations

Single-cylinder engines tend to produce significant vibrations because of unbalanced forces created by the movement of the large piston. Manufacturers typically use counterweights on the crankshaft to balance up to 85–90% of the primary unbalanced force. High-performance models, such as the Ducati Supermono, use a dummy connecting rod attached to a weighted rocker arm to counteract piston mass, reduce vibration, and allow higher engine revs. Despite these measures, single-cylinder engines require heavier flywheels than multi-cylinder engines, which can result in slower acceleration and uneven power delivery.

Applications

Most single-cylinder engines for vehicles run on petrol using a four-stroke cycle, but diesel single-cylinder engines are still used in stationary industrial applications due to their durability and efficiency.

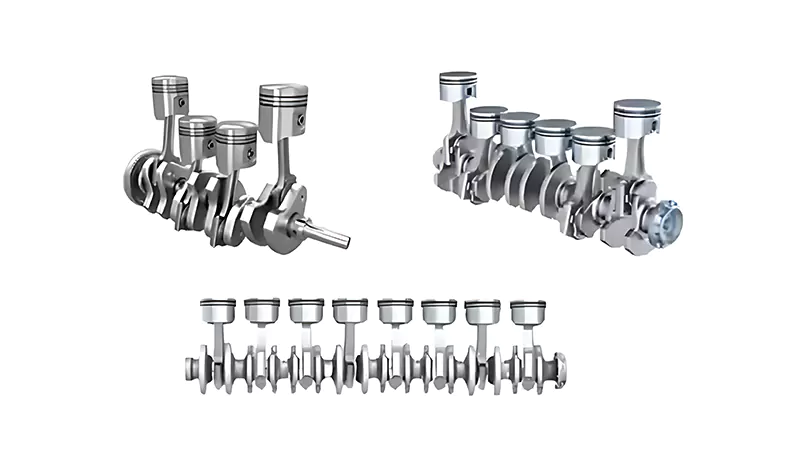

Inline engines, also known as straight engines, feature cylinders arranged in a single row along the crankshaft. Common configurations include I-4, I-6, and I-8 engines. Inline engines are renowned for their simplicity, cost-effectiveness, and ease of maintenance.

Inline engines provide even weight distribution along the engine block, contributing to good mechanical balance. They are relatively compact, making them suitable for small engine bays in passenger vehicles. Four-cylinder inline engines dominate the market because they offer an ideal balance between fuel economy, emissions, and manufacturing cost. BMW, for instance, is famous for its high-performance inline six-cylinder engines, which combine smooth operation with strong mid-range power.

Drawbacks

Long inline engines, such as I-6 or I-8, can be prone to flexing, leading to potential issues with rigidity under high load. Cooling can also be challenging because the longer engine block can create hotspots, especially at the center cylinders. The higher center of gravity compared to flat or V-type engines may negatively affect handling, and these engines can produce noticeable noise on uneven surfaces.

V-Type Engines

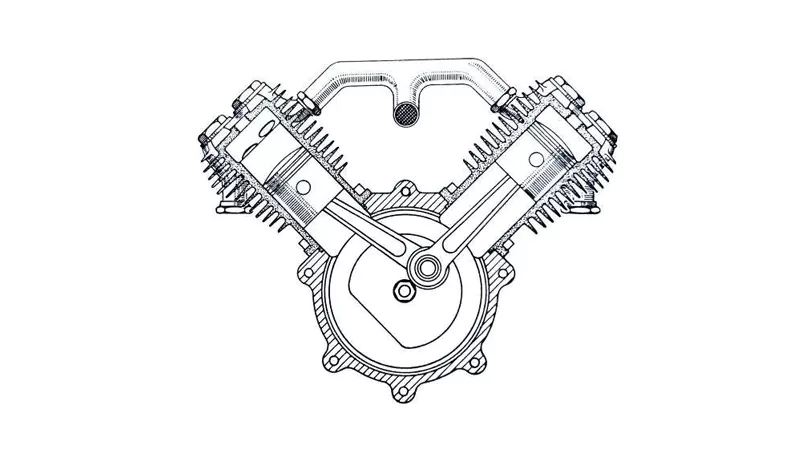

V-type engines arrange cylinders in two banks forming a V shape, with both banks sharing a common crankshaft. This configuration allows for better packaging of more cylinders in a limited engine bay. Common configurations include V6, V8, V10, and V12 engines.

Advantages

V-engines offer smoother operation than equivalent inline engines, thanks to better inherent balance. The V-shaped layout shortens engine length while maintaining cylinder capacity, making it ideal for high-performance and luxury cars. V-engines provide more compact packaging for larger engines, allowing manufacturers to fit six, eight, or even twelve cylinders into vehicles without requiring excessively long engine bays.

Applications

High-end motorcycles often use V4 engines for compact performance, while sedans, SUVs, and sports cars employ V6 and V8 layouts. Ferrari, Mercedes-AMG, and other performance brands rely heavily on V-type engines for their superior balance of power, smoothness, and size efficiency.

Limitations

V-engines are more complex, containing additional parts such as multiple cylinder heads, camshafts, and more extensive cooling systems. This complexity increases manufacturing difficulty, weight, and maintenance costs. Cooling can be problematic due to closely spaced cylinder banks, and fuel efficiency is generally lower than inline engines.

Flat and Boxer Engines

Flat engines, also called horizontally opposed engines, have cylinders positioned flat and opposite each other across the crankshaft. Boxer engines are a specialized form of flat engines in which opposing pistons mirror each other’s motion, achieving excellent balance and minimal vibration.

Advantages

Flat engines reduce the vehicle’s center of gravity, improving handling, stability, and cornering performance. The layout allows for smoother power delivery and efficient cooling, particularly when air-cooled designs are used. Porsche, Subaru, and Toyota currently produce boxer engines, with Porsche’s 911 featuring flat-six engines and Subaru’s BRZ and Toyota 86 employing flat-four layouts.

Drawbacks

Flat engines are wider than inline or V-type engines, which can complicate packaging in smaller cars. Maintenance can be more challenging due to the positioning of cylinder heads. Despite these challenges, the balance and stability offered by flat engines make them highly desirable in sports cars and performance vehicles.

W Engines

W engines use three or four banks of cylinders sharing a common crankshaft, forming a W shape when viewed from the front. Three-bank W engines are often called broad-arrow engines.

Advantages

W engines are shorter than equivalent V engines but wider, allowing manufacturers to fit more cylinders in a shorter length. This configuration offers high power output while saving longitudinal space in the engine bay. Volkswagen Group is known for mass-producing W engines, including W12 engines used in luxury vehicles such as the Audi A8 and Bentley Continental.

The complexity of W engines, including multiple cylinder heads and extensive componentry, increases production difficulty and maintenance costs. As a result, they remain rare and are primarily used in exotic and high-performance vehicles.

Rotary (Wankel) Engines

Rotary engines, developed and popularized by Mazda, employ a triangular rotor rotating eccentrically within an oval chamber. Unlike piston engines, Wankel engines complete the four-stroke cycle differently while achieving similar combustion outcomes.

Advantages

Rotary engines are lightweight, compact, and feature minimal moving parts, resulting in smooth operation and a low center of gravity. These engines are highly responsive and allow for high-revving performance in compact designs.

Limitations

Wankel engines consume more fuel, produce higher emissions, and require more frequent maintenance. The Mazda RX-8, the last production car to feature a rotary engine, was discontinued in 2012 largely due to these inefficiencies. While no mainstream vehicles currently use rotary engines, their engineering remains influential in performance car design.

Radial Engines

Radial engines have cylinders arranged radially around a central crankcase, resembling the spokes of a wheel. Historically used in aircraft, radial engines deliver high power and reliability. Cylinders fire in a specific alternating order to maintain smooth operation. While primarily for aviation, radial engines have occasionally been adapted for tanks, motorcycles, and even some cars in the past.

X, U, and H Engines

X Engines: Four-cylinder banks form an X around a common crankshaft. Early examples include Ford’s X-8 and the Packard X-2775. These engines offered high power but were heavy and mechanically complex, limiting widespread adoption.

U Engines: Two parallel straight engines with separate crankshafts coupled to a shared output shaft. This layout can cancel gyroscopic forces when crankshafts rotate oppositely and allows shared components, as seen in the Bugatti U-16 and Suzuki RG500 motorcycles.

H Engines: Two flat engines stacked with separate crankshafts geared to a common output shaft. H engines provide excellent mechanical balance and allow many cylinders in a compact longitudinal space. Famous examples include the Napier Sabre aircraft engines and the Lotus 43 Formula One car.

Opposed-Piston Engines

Opposed-piston engines feature two pistons per cylinder moving toward and away from each other, eliminating the need for cylinder heads. This design reduces heat loss, improves thermal efficiency, and lowers emissions. The longer effective stroke allows more complete combustion, but mechanical complexity and additional weight make them challenging compared to conventional engines. Despite these challenges, opposed-piston engines remain an innovative solution for specialized applications in automotive and industrial sectors.

Conclusion

From single-cylinder simplicity to the multi-bank sophistication of W, X, U, and H engines, each layout offers unique advantages and compromises in terms of power delivery, balance, packaging, cost, and maintenance. Inline engines provide affordability and fuel efficiency, V-engines offer compact high power, flat engines improve stability, and specialized engines cater to high-performance or industrial requirements. Understanding the differences in engine layouts is essential for selecting the right powertrain for specific vehicle applications.

As a professional engine manufacturer, we are committed to designing and producing high-quality engines that meet the demands of a wide range of automotive applications. Whether for passenger cars, or high-performance vehicles, our expertise ensures reliable and efficient engine solutions. Contact us today for your project.