What Is an Engine Block?

The engine block is the main structure of an engine that houses the cylinders, pistons, crankshaft, and other essential components. It provides the foundation for the engine and ensures that all moving parts operate smoothly and efficiently. In addition to its structural role, the engine block also serves as a medium for heat management, fluid channels, and mechanical integration.

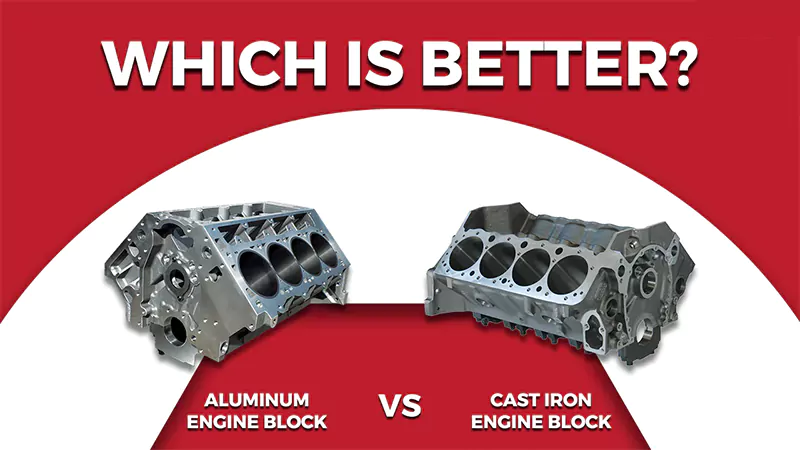

Modern engine blocks are designed to withstand high temperatures, extreme pressures, and continuous mechanical stress. The choice of material is therefore a crucial factor in ensuring the engine’s performance and lifespan.

Common Engine Block Materials

1. Cast Iron

Advantages of Cast Iron:

- High Strength and Durability: Cast iron is highly resistant to wear and deformation, making it suitable for engines that operate under heavy loads.

- Excellent Machinability: Cast iron can be precisely machined to create complex geometries needed for cylinder bores and coolant channels.

- Vibration Dampening: Its dense structure helps reduce engine vibrations and noise.

Disadvantages of Cast Iron:

- Heavy Weight: Cast iron engine blocks are heavier than alternative materials, which can negatively impact fuel efficiency and vehicle handling.

- Corrosion Susceptibility: Though generally resistant, cast iron can corrode over time if not properly protected or maintained.

- Heat Conductivity: Cast iron has lower thermal conductivity compared to aluminum, which may result in slower heat dissipation.

2. Aluminum Alloy

Advantages of Aluminum Alloy:

- Lightweight: Reduces overall vehicle weight, improving fuel economy and handling.

- Good Heat Dissipation: Aluminum conducts heat effectively, helping maintain optimal engine temperatures and reduce overheating risks.

- Corrosion Resistance: Aluminum naturally forms an oxide layer, which helps resist corrosion over time.

Disadvantages of Aluminum Alloy:

- Lower Strength: Aluminum is softer than cast iron, which may lead to wear over time, especially in high-performance applications.

- Cost: Aluminum engine blocks are generally more expensive to produce than cast iron blocks.

- Complex Manufacturing: Aluminum requires advanced casting and machining techniques, which can increase production complexity.

Recommendation:

If you are looking to purchase high-quality aluminum engine blocks or cylinder heads, Xinjing Engine offers premium products along with professional service. Their solutions ensure both reliability and performance for a wide range of applications.

3. Compacted Graphite Iron (CGI)

Advantages of CGI:

- High Strength-to-Weight Ratio: CGI is stronger than traditional cast iron while being lighter, making it suitable for high-performance and diesel engines.

- Thermal Efficiency: Offers better heat transfer than cast iron, enhancing engine cooling and performance.

- Durability: Resists fatigue and cracking, which is crucial for heavy-duty applications.

Disadvantages of CGI:

- Manufacturing Difficulty: CGI requires specialized casting processes, which may increase production costs.

- Machining Challenges: The hardness of CGI makes it harder to machine compared to cast iron and aluminum.

4. Hybrid Materials

Advantages of Hybrid Materials:

- Balanced Performance: Combines the lightweight nature of aluminum with the strength of cast iron.

- Customizable Properties: Allows engineers to tailor materials to meet performance, durability, and fuel efficiency goals.

- Advanced Applications: Often used in high-performance sports cars and racing engines.

Disadvantages of Hybrid Materials:

- High Cost: Material complexity and specialized manufacturing increase production expenses.

- Repair Difficulty: Repairing hybrid engine blocks can be challenging due to the combination of materials.

Factors Influencing Engine Block Material Selection

1. Vehicle Type

2. Engine Size and Performance

3. Cost Considerations

4. Manufacturing Techniques

Modern casting techniques, such as sand casting, die casting, and precision casting, influence the choice of material. Certain materials require more advanced machinery and skilled labor, which may affect production timelines and costs.

Heat Management and Material Performance

Engine block materials play a crucial role in heat management. Efficient heat transfer ensures that the engine operates at optimal temperatures, preventing overheating and prolonging the lifespan of internal components.

- Cast Iron: Retains heat longer, providing stable operating temperatures but slower cooling.

- Aluminum Alloy: Offers rapid heat dissipation, reducing the risk of hotspots and improving efficiency.

- CGI and Hybrid Materials: Provide a balance of heat retention and transfer, suitable for high-performance applications.

Wear Resistance and Longevity

The engine block material directly affects wear resistance. Pistons, bearings, and cylinder liners exert continuous friction, and a material that resists wear extends engine life.

- Cast Iron: Excellent wear resistance, especially when paired with durable cylinder liners.

- Aluminum Alloy: May require hardened coatings or inserts to improve wear resistance.

- CGI: Provides high durability without significant weight penalties.

Environmental and Sustainability Considerations

Increasingly, automotive manufacturers consider the environmental impact of engine block materials. Aluminum is highly recyclable, reducing the ecological footprint. Cast iron and CGI, while durable, are heavier and may require more energy to produce and transport.

Innovations in Engine Block Materials

Modern engineering has introduced several innovations in engine block materials:

- Aluminum with Ceramic Coatings: Enhances wear resistance and heat management.

- Magnesium Alloys: Even lighter than aluminum, used in specialized racing engines.

- Composite Materials: Carbon fiber reinforced polymers are being explored for ultra-lightweight applications.

- Additive Manufacturing: 3D printing allows for complex internal geometries that improve cooling and structural integrity.

These innovations aim to optimize the balance between strength, weight, efficiency, and durability.

Conclusion

The choice of engine block material significantly affects the performance, efficiency, and longevity of an engine. While cast iron offers durability and cost-effectiveness, aluminum alloys provide lightweight and improved heat dissipation. Compacted Graphite Iron and hybrid materials combine the advantages of traditional materials, making them suitable for high-performance applications. Manufacturers must consider vehicle type, engine performance, cost, and manufacturing capabilities when selecting the optimal material.

Understanding engine block materials helps enthusiasts, engineers, and vehicle owners make informed decisions when upgrading, repairing, or purchasing engines. As automotive technology continues to evolve, new materials and manufacturing techniques will further enhance engine performance, fuel efficiency, and sustainability.