The cylinder head is one of the most critical components of an internal combustion engine. It sits atop the engine block and houses essential parts such as the intake and exhaust valves, spark plugs, and passages for coolant and oil. Over time, due to heat cycles, pressure, and wear, the surface of a cylinder head can become warped or uneven. This can lead to compression loss, coolant leaks, and decreased engine performance. One effective method to restore its flatness and ensure proper sealing with the engine block is skimming the cylinder head.

In this article, we will dive into what cylinder head skimming is, why it is necessary, how it is done, and the precautions to take to maintain engine longevity. Whether you are a professional mechanic or a car enthusiast, understanding this process is essential for keeping your engine running efficiently.

What Is Cylinder Head Skimming?

Cylinder head skimming, also known as resurfacing, is the process of removing a thin layer of metal from the cylinder head’s surface. This is done to restore a perfectly flat mating surface that interfaces with the engine block. Over time, the cylinder head can warp due to excessive heat, engine overheating incidents, or uneven torque distribution when tightening the head bolts.

Even a small deviation in flatness can lead to engine problems such as:

- Head gasket failure

- Coolant leakage

- Reduced compression

- Uneven combustion

Skimming ensures that the cylinder head surface is perfectly level, allowing the head gasket to form a tight seal and the engine to operate at peak efficiency.

Signs That Your Cylinder Head Needs Skimming

Before deciding to skim a cylinder head, it’s important to identify the symptoms that indicate warping or surface irregularities. Common signs include:

- Engine Overheating

Repeated overheating can cause the cylinder head to warp. If the engine consistently runs hotter than normal, it may be time to inspect the head. - Coolant Leaks

Warped cylinder heads can cause the head gasket to fail, leading to visible coolant leaks around the head or between cylinders. - Loss of Compression

Low compression in one or more cylinders can indicate that the cylinder head surface is not sealing properly with the block. - White Smoke from Exhaust

Coolant entering the combustion chamber due to head gasket failure produces white exhaust smoke. - Engine Misfire

Uneven sealing can lead to misfires and reduced engine performance.

If any of these issues are observed, inspecting the cylinder head for warping and considering skimming can prevent more serious engine damage.

Materials and Tools Needed for Skimming

Cylinder head skimming requires precision and the right equipment. While it’s generally done by professional machine shops, understanding the tools and materials involved helps in making informed decisions:

- Surface Grinder or Milling Machine: High-precision equipment to remove a uniform layer of metal.

- Dial Gauge or Straight Edge: Used to measure warping and determine the amount of material to remove.

- Coolant or Lubricant: Ensures smooth cutting and prevents overheating during the process.

- Cylinder Head Cleaning Tools: Wire brushes or chemical cleaners to remove carbon deposits and oil residues before skimming.

It’s important to note that even minor mistakes in the skimming process can alter engine performance or create new problems. Therefore, accuracy and careful measurement are crucial.

The Cylinder Head Skimming Process

1. Inspection and Measurement

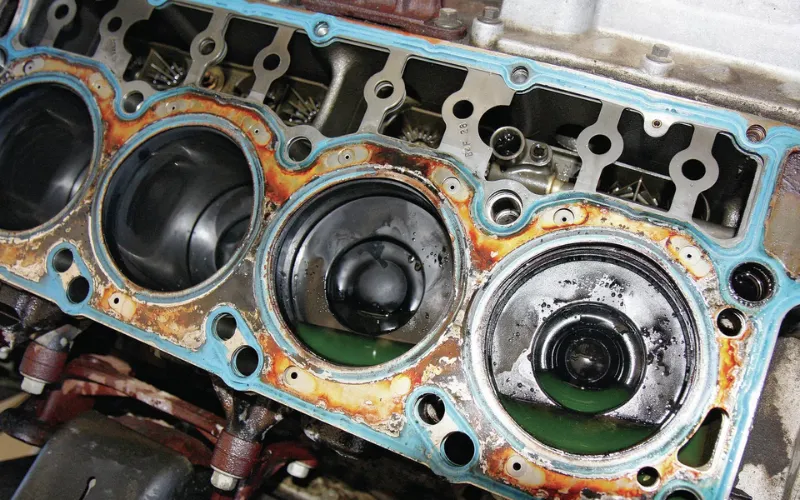

Before any material is removed, the cylinder head must undergo a thorough inspection. This begins with a detailed cleaning to remove oil, carbon deposits, and any debris from previous engine operation. Once clean, the head should be checked for cracks, pitting, corrosion, or any other structural damage that might compromise its integrity.

To assess warping, a straight edge and a feeler gauge are commonly used. The straight edge is placed across different sections of the cylinder head surface, and the feeler gauge measures gaps between the tool and the metal. Most manufacturers recommend tolerances of just a few thousandths of an inch; even minor deviations can affect head gasket sealing. If the cylinder head exceeds these tolerances, skimming becomes necessary to restore flatness and ensure proper engine performance.

2. Preparation

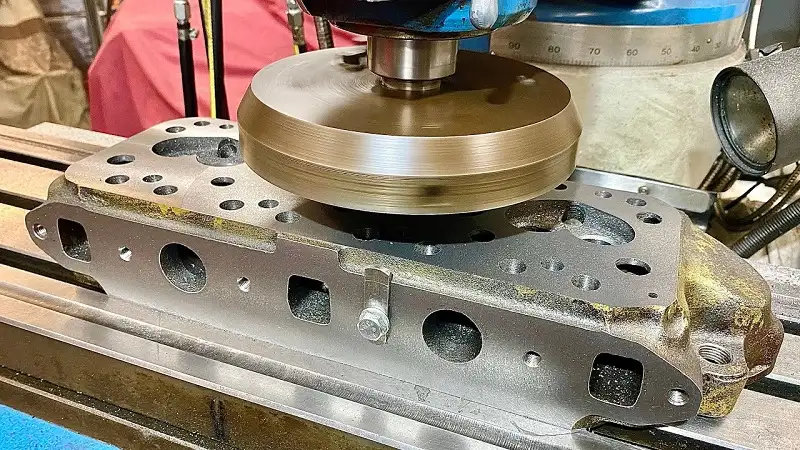

Once the inspection confirms that skimming is needed, the cylinder head is carefully secured on a milling machine or surface grinder. Proper alignment is critical to ensure that material is removed evenly across the entire surface. Any misalignment can create new warping or uneven surfaces, which can worsen sealing issues instead of solving them.

Before starting the cutting process, it is essential to remove all oil, grease, and coolant residues. Contaminants can interfere with the grinding process and reduce precision. Additionally, the operator must confirm that the machine is properly calibrated, with the cutting tools sharp and suitable for the cylinder head material—commonly aluminum or cast iron.

3. Material Removal

With the head in position and the machine ready, the skimming process begins. The surface grinder or milling machine removes a very thin layer of metal, typically between 0.1 mm to 0.5 mm, depending on the degree of warping. This step requires steady control, as excessive material removal can alter the combustion chamber volume, unintentionally increasing the compression ratio and potentially affecting engine performance.

During cutting, coolant or lubricant is often applied to prevent overheating, which can introduce new distortions or micro-cracks. The operator may make multiple light passes rather than a single deep cut, ensuring a consistent, uniform surface across the entire head.

4. Finishing

After the initial material removal, the cylinder head surface may still require fine finishing. This often involves using an abrasive pad or stone to smooth out minor imperfections left by the milling or grinding process. A smooth surface is crucial for optimal head gasket contact, as even microscopic roughness can lead to leaks under high-pressure combustion conditions.

At this stage, some machine shops also perform a light polish or lapping to further improve flatness and surface texture. This ensures that the cylinder head will form a perfect seal when reinstalled on the engine block.

5. Final Inspection

The last step is a thorough final inspection. The skimming process should be double-checked using the straight edge and feeler gauge to confirm that the surface is perfectly flat and free from deviations. Any areas that still show gaps or irregularities may require additional light skimming or polishing.

Once the measurements are within manufacturer specifications, the cylinder head is ready for reinstallation. At this point, valve seats and clearances should also be checked, as skimming can slightly alter these dimensions. Proper reassembly ensures that the engine will maintain compression, prevent leaks, and operate efficiently.

Benefits of Skimming Cylinder Heads

Skimming the cylinder head provides several advantages:

- Restores Proper Compression

A flat surface ensures the head gasket seals correctly, maintaining compression in each cylinder. - Prevents Coolant Leaks

Eliminating warps prevents coolant from leaking between the head and engine block. - Enhances Engine Efficiency

Proper sealing improves combustion efficiency, which translates to better fuel economy and smoother engine operation. - Extends Engine Lifespan

By preventing gasket failures and uneven combustion, skimming can prolong engine life and reduce costly repairs.

Risks and Considerations

While skimming is highly beneficial, there are some considerations to keep in mind:

- Material Limitations

Aluminum and cast iron cylinder heads can only tolerate a limited amount of material removal. Excessive skimming can compromise head integrity. - Impact on Compression Ratio

Skimming reduces combustion chamber volume, slightly increasing compression ratio. For high-performance engines, even small changes can affect engine behavior. - Professional Expertise Required

Skimming requires precise machinery and skilled operators. Attempting this without proper tools and experience can cause more harm than good. - Check Valve and Seat Geometry

After skimming, valve clearance and seating may need adjustment to maintain proper engine function.

When to Consider Cylinder Head Replacement Instead

Sometimes, skimming may not be the best solution. Cylinder heads with severe cracks, extensive corrosion, or metal fatigue may require replacement. In such cases, a new or remanufactured cylinder head ensures reliable performance and avoids recurring issues. If you are looking to purchase a cylinder head, you can contact XINJIN. We provide high-quality, cost-effective products along with excellent customer service. Any questions or concerns can be addressed directly by our professional team.

Conclusion

Cylinder head skimming is a vital process for maintaining engine performance, especially when dealing with warping caused by overheating or prolonged use. By restoring a perfectly flat surface, skimming ensures proper head gasket sealing, consistent compression, and efficient engine operation. While it offers numerous benefits, it is crucial to have the process done accurately and by skilled professionals to avoid unintended consequences.

For mechanics, car enthusiasts, or automotive workshops, understanding cylinder head skimming and its implications is key to optimizing engine performance and longevity. Whether addressing minor warping or preparing a cylinder head for a performance build, proper skimming can make a significant difference in overall engine health.