The cylinder head is one of the most important components of any internal combustion engine. Serving as the interface between the combustion chamber and the rest of the engine, it houses critical parts such as valves, spark plugs, and fuel injectors. Among the many parameters that reflect engine health and performance, cylinder head temperature (CHT) is often overlooked, yet it plays a crucial role in preventing engine damage, optimizing efficiency, and extending component lifespan.

In this guide, we will cover everything you need to know about cylinder head temp: what it is, why it matters, how to measure it, factors that influence it, optimal ranges for different engines, strategies for management, and its significance in performance tuning. This comprehensive understanding is essential for car enthusiasts, professional mechanics, and performance tuners alike.

What is Cylinder Head Temperature?

Cylinder head temperature refers to the heat generated within the cylinder head during engine operation. Unlike the standard coolant temperature, which represents an average measurement of the engine’s cooling system, CHT focuses on the actual temperature at the cylinder head itself. This localized heat comes from three main sources:

- Combustion Heat: Each time the air-fuel mixture ignites, temperatures rise sharply inside the combustion chamber, transferring heat to the cylinder head.

- Frictional Heat: Moving components such as valves and camshafts generate friction, adding to the thermal load.

- Heat Transfer from Engine Components: The engine block and exhaust system also radiate heat, which further raises the cylinder head temperature.

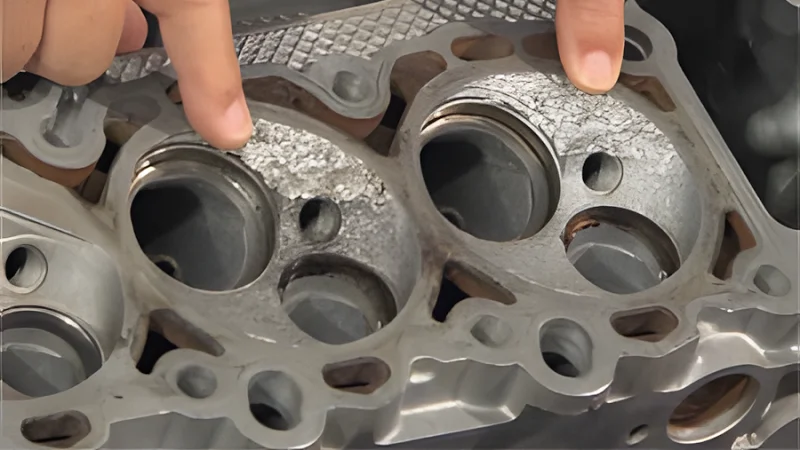

High cylinder head temperatures, if left unchecked, can lead to serious issues such as warped heads, blown head gaskets, valve seat damage, and even catastrophic engine failure. Understanding cylinder head temperature is especially important for high-performance engines, turbocharged vehicles, and diesel engines, all of which tend to generate higher thermal loads.

Why Cylinder Head Temperature Matters

1. Engine Performance

2. Engine Longevity

3. Safety

Factors Affecting Cylinder Head Temperature

Several factors influence cylinder head temperature, ranging from engine load to environmental conditions:

- Engine Load: Heavy towing, aggressive acceleration, or high-speed driving increases combustion temperatures, raising CHT.

- Ambient Temperature: Hot weather reduces the efficiency of air- and liquid-cooled engines, elevating cylinder head heat.

- Cooling System Efficiency: Radiator size, coolant type, water pump condition, and proper airflow all affect CHT. A restricted or malfunctioning cooling system can lead to dangerously high temperatures.

- Combustion Conditions: Lean fuel mixtures, advanced ignition timing, and high turbo boost pressure all increase thermal stress on the cylinder head.

- Engine Design: Aluminum cylinder heads dissipate heat faster than cast iron but are more susceptible to warping. The design of coolant passages and valve placement also affects temperature distribution.

- Maintenance Status: Deposits, carbon buildup, or worn components can interfere with heat dissipation, causing localized overheating.

Understanding these factors allows mechanics and car enthusiasts to diagnose problems more effectively and make informed tuning decisions.

How to Measure Cylinder Head Temperature

1. Thermocouples

2. Infrared Sensors

3. Engine Management Systems (ECUs)

Modern ECUs can estimate CHT using algorithms based on coolant temperature, engine load, and RPM. While indirect, this approach allows for real-time adjustments in ignition timing, fuel mixture, or turbo boost to protect the engine from excessive heat.

Optimal Cylinder Head Temperature Ranges

The ideal cylinder head temperature range varies by engine type and operating conditions:

- Naturally Aspirated Gasoline Engines: Typically operate between 190–250°F (88–121°C).

- Turbocharged Gasoline Engines: May reach 250–300°F (121–149°C) during high-load conditions.

- Diesel Engines: Usually run hotter, between 300–400°F (149–204°C), due to higher compression and combustion pressures.

Maintaining CHT within these ranges is critical to avoid pre-ignition, warping, and head gasket failure. For high-performance engines, continuous monitoring is strongly recommended.

Strategies to Manage Cylinder Head Temperature

1. Optimize Cooling System

- Upgrade radiators or intercoolers for high-load or performance engines.

- Use high-quality coolant with proper additives to improve heat transfer.

- Ensure unobstructed coolant flow and check for leaks, blockages, or worn water pumps.

2. Engine Tuning Adjustments

- Maintain correct air-fuel mixtures to avoid lean combustion.

- Adjust ignition timing to reduce pre-ignition risk.

- Monitor and regulate turbo boost in forced induction engines.

3. Thermal Management Components

- Use cylinder head gaskets and head studs designed for high temperatures.

- Apply thermal barrier coatings to combustion chambers or exhaust ports.

- Install oil coolers or upgraded oil pans to assist heat dissipation.

4. Operational Awareness

- Avoid prolonged high-load driving in extreme temperatures without monitoring.

- Gradually warm up engines to reduce thermal shock.

- Keep a close eye on CHT monitoring for tuning if using aftermarket or high-performance modifications.

Common Misconceptions About Cylinder Head Temperature

- Coolant Temperature Alone Reflects Engine Heat: While coolant readings provide useful data, they do not reflect localized CHT spikes under heavy load.

- High CHT Always Indicates Damage: Temporary spikes are normal under extreme conditions. It is sustained overheating that causes problems.

- Aluminum Cylinder Heads Don’t Overheat: Aluminum dissipates heat efficiently but is more prone to warping than cast iron when exposed to prolonged heat.

Cylinder Head Temperature in Performance Applications

In racing or high-performance vehicles, cylinder head temp becomes even more critical. Engines pushed to their limits experience extreme thermal stress, and real-time CHT monitoring allows for proactive adjustments:

- ECUs can dynamically modify ignition timing, fuel mixture, and turbo boost to prevent overheating.

- Advanced thermocouples and data logging provide precise temperature feedback.

- Aftermarket components such as high-flow radiators, intercoolers, and thermal coatings help manage the extra heat generated during high-RPM or boost-heavy operation.

Proper CHT management ensures consistent performance, protects engine components, and reduces the likelihood of catastrophic failure during competitive conditions.

Conclusion

Cylinder head temperature is a vital metric for engine health, efficiency, and safety. By understanding what CHT is, the factors that affect it, how to measure it, and strategies to manage it, vehicle owners and mechanics can make informed decisions that extend engine life and enhance performance. Proper cooling system maintenance, tuning adjustments, thermal management upgrades, and real-time monitoring are essential to keeping CHT within safe limits.

Whether you drive a daily commuter, a heavy-duty diesel truck, or a high-performance racing vehicle, prioritizing cylinder head temp today ensures reliable operation and prevents costly engine repairs tomorrow.

FAQ Section:

Q1: What is cylinder head temperature (CHT)?

A1: Cylinder head temperature is the heat measured at the engine’s cylinder head, which reflects the thermal stress from combustion, friction, and heat transfer from other components.

Q2: How can I measure cylinder head temperature?

A2: CHT can be measured using thermocouples, infrared sensors, or estimated through engine management systems (ECUs) for real-time monitoring.

Q3: What is the optimal cylinder head temperature range?

A3: Gasoline engines usually operate between 190–250°F (88–121°C), turbocharged engines between 250–300°F (121–149°C), and diesel engines between 300–400°F (149–204°C).

Q4: What causes cylinder head overheating?

A4: Overheating can be caused by high engine load, inefficient cooling systems, lean fuel mixtures, advanced ignition timing, or blocked coolant passages.

Q5: Why is monitoring CHT important for high-performance engines?

A5: High-performance engines generate more heat, and monitoring CHT helps prevent detonation, engine damage, and ensures optimal performance under heavy loads.