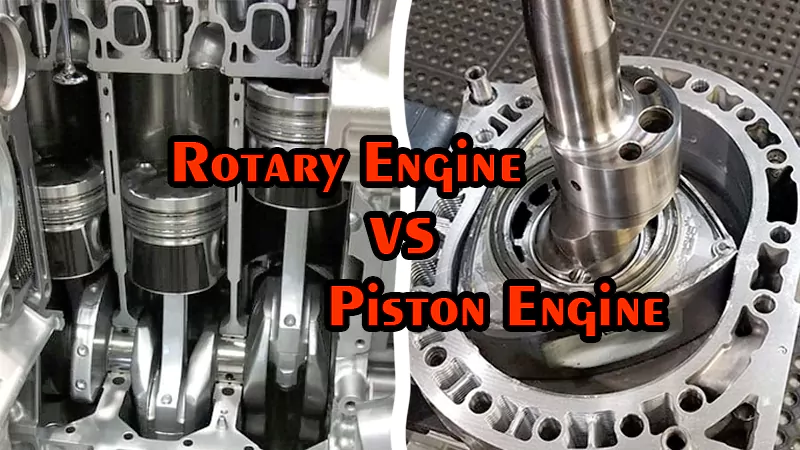

When it comes to internal combustion engines, most people immediately think of the conventional piston engine with its cylinders, pistons, connecting rods, and crankshaft. However, there is another fascinating design that has captured the imagination of engineers and car enthusiasts alike: the rotary engine, also known as the Wankel engine. While both serve the same purpose—converting fuel into mechanical power—the way they achieve this goal is fundamentally different. Understanding the distinctions between a rotary engine and a piston engine is essential for appreciating their advantages, disadvantages, and why one has dominated the automotive industry while the other remains a niche curiosity.

How a Piston Engine Works?

The piston engine, also called a reciprocating engine, relies on pistons that move up and down inside cylinders. Each piston is connected to a crankshaft through a connecting rod. The classic four-stroke cycle—intake, compression, power, and exhaust—takes place as the piston moves through its strokes. During the intake stroke, air and fuel enter the combustion chamber. The piston then compresses this mixture, and when the spark plug ignites it, the resulting explosion forces the piston downward. This motion is transferred to the crankshaft, which converts it into rotational motion to drive the wheels. Finally, the piston moves upward again to expel exhaust gases.

This process is repeated thousands of times per minute across multiple cylinders. The reason the piston engine has become so successful is its balance of efficiency, torque, durability, and adaptability. Manufacturers can build them in almost any size, from tiny motorcycle engines to massive diesel engines for ships and heavy equipment.

How a Rotary Engine Works?

The rotary engine takes a very different approach. Instead of pistons moving up and down, it uses a triangular-shaped rotor that turns within an oval-like housing called an epitrochoid. As the rotor turns, its three tips—sealed with special strips called apex seals—remain in contact with the housing, creating three separate chambers. Just like the piston engine, the four stages of intake, compression, combustion, and exhaust still occur, but they happen in different chambers simultaneously as the rotor spins.

The rotary engine does not have a conventional crankshaft. Instead, it uses an eccentric shaft. The rotor’s movement pushes against this shaft, creating continuous rotational motion. Interestingly, while the rotor makes one complete turn, the eccentric shaft actually completes three revolutions. This characteristic gives the rotary engine a remarkably smooth power delivery and the ability to achieve high RPMs compared to piston engines.

Power Delivery and Performance

When comparing a rotary engine vs piston engine in terms of performance, the rotary stands out for its compact size and high power-to-weight ratio. A relatively small rotary engine can generate power figures that rival much larger piston engines. This is one reason why Mazda’s legendary RX-7 sports car, powered by a twin-rotor engine, became so iconic among enthusiasts. The engine’s ability to rev freely and produce a thrilling, linear surge of power makes it ideal for racing, drifting, and other motorsport applications.

However, the rotary’s strength at high RPM comes with a trade-off. At lower engine speeds, torque output is generally weaker than that of piston engines. This means that for everyday driving, a piston engine feels more responsive, especially when accelerating from a stop. Drivers of rotary-powered cars often have to rev the engine higher to access its full potential, which may not be ideal for typical commuting.

Efficiency and Fuel Consumption

One of the most significant weaknesses of the rotary engine is fuel efficiency. The shape of the combustion chamber is long and narrow, which makes complete combustion difficult. The flame front has to travel further, leading to pockets of unburned fuel. This results in poor fuel economy compared to piston engines of similar output.

The piston engine, by contrast, has a more compact combustion chamber that promotes more efficient burning of the air-fuel mixture. As a result, piston engines generally achieve better miles per gallon, especially at low and mid-range RPMs. In an era where fuel economy standards and consumer concerns are increasingly important, this has been a decisive factor in why piston engines dominate mass production.

Emissions and Environmental Challenges

Another drawback of the rotary engine is emissions. Because of the incomplete combustion issue, rotary engines tend to produce higher levels of hydrocarbons. Meeting modern emission regulations has always been a struggle. Mazda worked extensively to improve this with the Renesis engine used in the RX-8, redesigning the intake and exhaust ports to minimize overlap and improve combustion. While this reduced emissions compared to earlier designs, it was still not enough to keep pace with tightening global standards.

The piston engine also faces environmental challenges, but continuous improvements in fuel injection, turbocharging, and hybrid integration have allowed it to evolve and remain viable. Rotary engines have not enjoyed the same level of investment from multiple manufacturers, leaving Mazda as the sole champion of the design.

Reliability and Maintenance

When discussing rotary engine vs piston engine reliability, the piston engine is generally considered more durable and longer-lasting. With decades of refinement, piston engines are known for running hundreds of thousands of miles with proper maintenance.

When discussing rotary engine vs piston engine reliability, the piston engine is generally considered more durable and longer-lasting. With decades of refinement, piston engines are known for running hundreds of thousands of miles with proper maintenance.The rotary engine, on the other hand, has an infamous weak point: the apex seals. These seals are critical for maintaining compression in the chambers. Over time, they are prone to wear, leading to loss of power, hard starting, and in severe cases, complete engine failure. While enthusiasts often argue that proper maintenance and frequent oil checks can keep a rotary engine healthy, the reality is that it demands more attention than a piston engine, which has discouraged many everyday drivers.

Size, Weight, and Packaging

One of the most appealing qualities of the rotary engine is its compact size. A rotary can produce impressive power while occupying far less space than a piston engine of similar output. This allows for lower hood lines, better weight distribution, and lighter vehicles. Sports cars like the RX-7 benefited greatly from this characteristic, achieving excellent handling thanks to the engine’s small footprint and placement near the center of the chassis.

The piston engine, although larger, offers more flexibility in configuration. Inline, V-shaped, and boxer layouts give designers options for balancing packaging and performance. While heavier, piston engines can be designed to deliver more torque and withstand the demands of heavy-duty applications.

Why the Piston Engine Won the Mainstream

When analyzing rotary engine vs piston engine from a historical perspective, it becomes clear why the piston engine became the standard choice for mass production. Fuel efficiency, emissions compliance, durability, and versatility all tipped the scale in favor of piston designs. Consumers demanded engines that were cost-effective, reliable, and practical for everyday use.

The rotary engine, while innovative and exciting, failed to meet these demands on a large scale. High fuel consumption, maintenance concerns, and regulatory hurdles limited its adoption. Mazda’s perseverance kept the rotary alive longer than most, but even they had to discontinue the RX-8 in 2012 due to emission regulations.

The story of the rotary engine does not end in the past. Mazda has continued research, and in 2023 it reintroduced a rotary engine not as a primary power source but as a range extender in the Mazda MX-30 plug-in hybrid. In this role, the compact size and smooth operation of the rotary make it ideal for generating electricity without driving the wheels directly. Beyond cars, rotary engines also find use in drones, motorcycles, and small aircraft where weight and packaging matter more than ultimate efficiency.

Looking forward, the rotary engine is unlikely to replace the piston engine in mainstream cars. However, as a specialized solution for certain applications, it still has a future. Enthusiasts also continue to keep the rotary spirit alive through restorations, modifications, and motorsport.

Conclusion

The debate of rotary engine vs piston engine is not simply about which is better. Each has unique strengths that make it suitable for different purposes. The piston engine remains king of the road due to its efficiency, reliability, and adaptability, while the rotary engine holds a special place in automotive history for its innovation, compact design, and unforgettable high-revving performance. For everyday drivers, the piston engine is the logical choice. For enthusiasts, engineers, and dreamers, the rotary remains a symbol of what happens when we challenge convention and think differently about how power can be created.