Engines may look like a single solid piece of machinery from the outside, but inside they are made up of many complex components working together. Understanding these parts and how they function is the foundation of knowing how engines produce power. Below, we’ll take a closer look at engine configurations and the most important engine components in detail.

Common Engine Layouts

The heart of every engine is the cylinder, where fuel combustion takes place. Small machines like lawn mowers usually have a single cylinder, but automobiles typically use multiple cylinders — four, six, or eight are the most common.

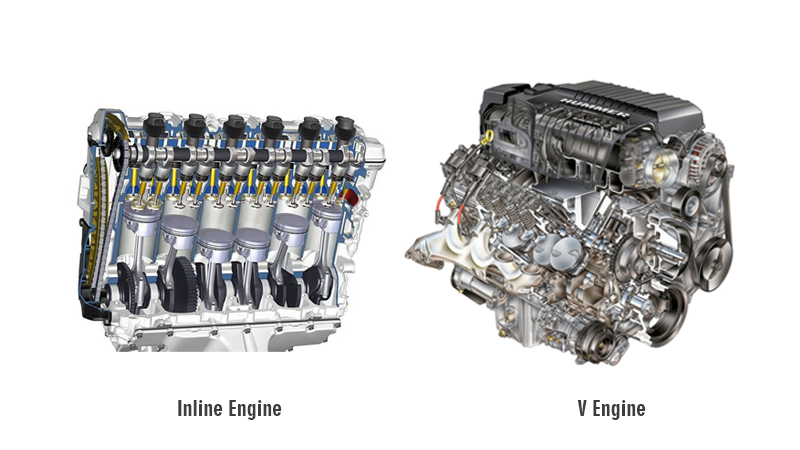

Multi-cylinder engines can be arranged in several different layouts, and each comes with its own strengths and weaknesses.

Inline Engines

- All cylinders are arranged in a straight line within a single bank.

- Inline-four engines are the most widely used across the automotive industry.

Pros: Compact, simple to manufacture, easy to service.

Cons: Less smooth in larger sizes, limited scalability.

V-Type Engines

- Cylinders are divided into two banks set at an angle, forming a V-shape.

- Found in many V6 and V8 engines.

Pros: Shorter overall length compared to inline designs, good balance for higher power, suitable for larger vehicles.

Cons: More expensive to build, tighter engine bays make servicing more complex.

Flat / Boxer Engines

- Cylinders are positioned opposite each other, lying flat.

- Known for use by Subaru and Porsche.

Pros: Naturally balanced, reduces vibration, lowers center of gravity for better handling.

Cons: Wider footprint, more costly to manufacture.

Essential Engine Components

1. Spark Plug

Provides the ignition source that lights the air-fuel mixture inside the cylinder. Precise timing is critical; a spark that is too early or too late can cause misfires, poor fuel economy, or even engine damage.

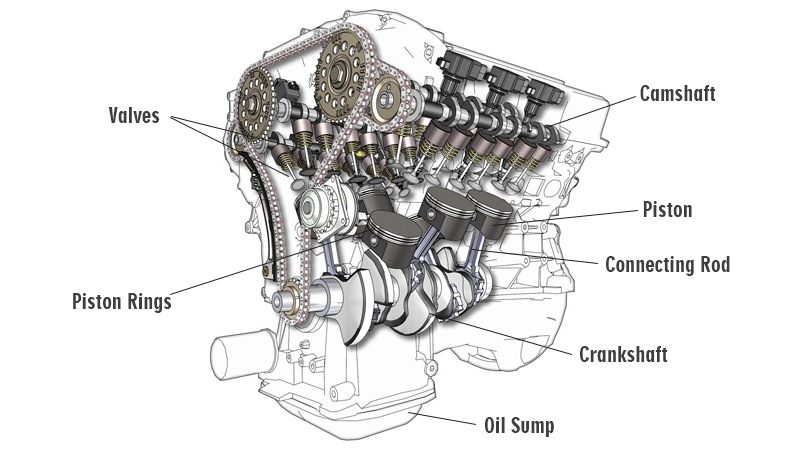

2. Valves

Control the flow of gases in and out of the cylinder.

- Intake valves allow fresh air and fuel in.

- Exhaust valves release burned gases.

During compression and combustion, both must remain sealed to maintain chamber pressure. Modern engines often use variable valve timing to maximize efficiency and performance.

3. Piston

A cylindrical metal component that moves up and down inside the cylinder. The piston directly translates the force of combustion into motion. High-performance pistons are typically made from lightweight aluminum alloys.

4. Piston Rings

Thin rings fitted around the piston to ensure a tight seal.

- They prevent combustion gases from leaking into the crankcase.

- They also stop engine oil from entering the combustion chamber.

When piston rings wear out, oil consumption increases and the engine may begin to “burn oil.” Advances in ring materials have made modern engines more durable and efficient.

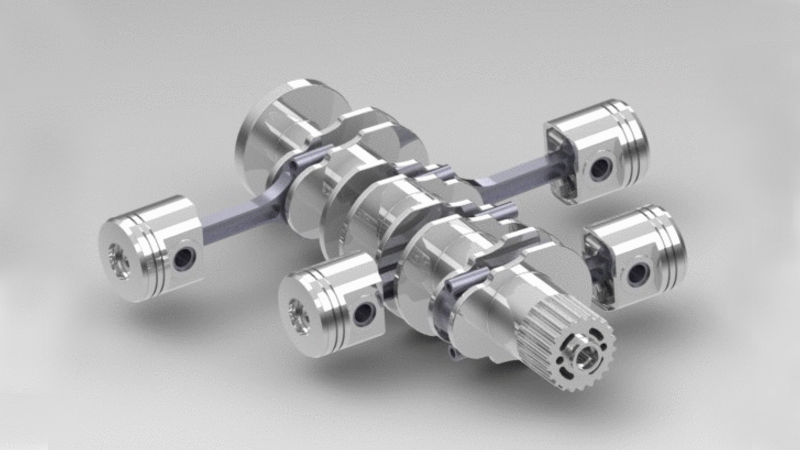

5. Connecting Rod

Links the piston to the crankshaft. It pivots at both ends to handle the changing angles of motion. Because it experiences extreme stress, the connecting rod must be strong yet lightweight, often made from forged steel or performance alloys.

Transforms the pistons’ up-and-down motion into rotational force, which ultimately drives the vehicle’s wheels. Precision balancing is essential; any imbalance can cause vibration and reduce engine life.

7. Oil Sump (Oil Pan)

Located at the bottom of the engine, the sump stores engine oil. An oil pump circulates the oil to lubricate moving components, reduce friction, and control heat. Without proper lubrication, an engine would seize in minutes.

Conclusion

Every component of an engine — from the spark plug to the crankshaft — plays a critical role in making the system work as a whole. The choice of engine layout, the quality of materials, and the precision of design all determine performance, durability, and cost.

For drivers, understanding these basics helps explain why engines differ from one vehicle to another, and why maintenance is so important for long-term reliability.